Oil shale liquefaction method

A technology of oil shale and reactor, which is applied in the field of oil shale liquefaction, can solve the problem of low calorific value of bio-oil, achieve high quality, be conducive to industrial application, and be easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

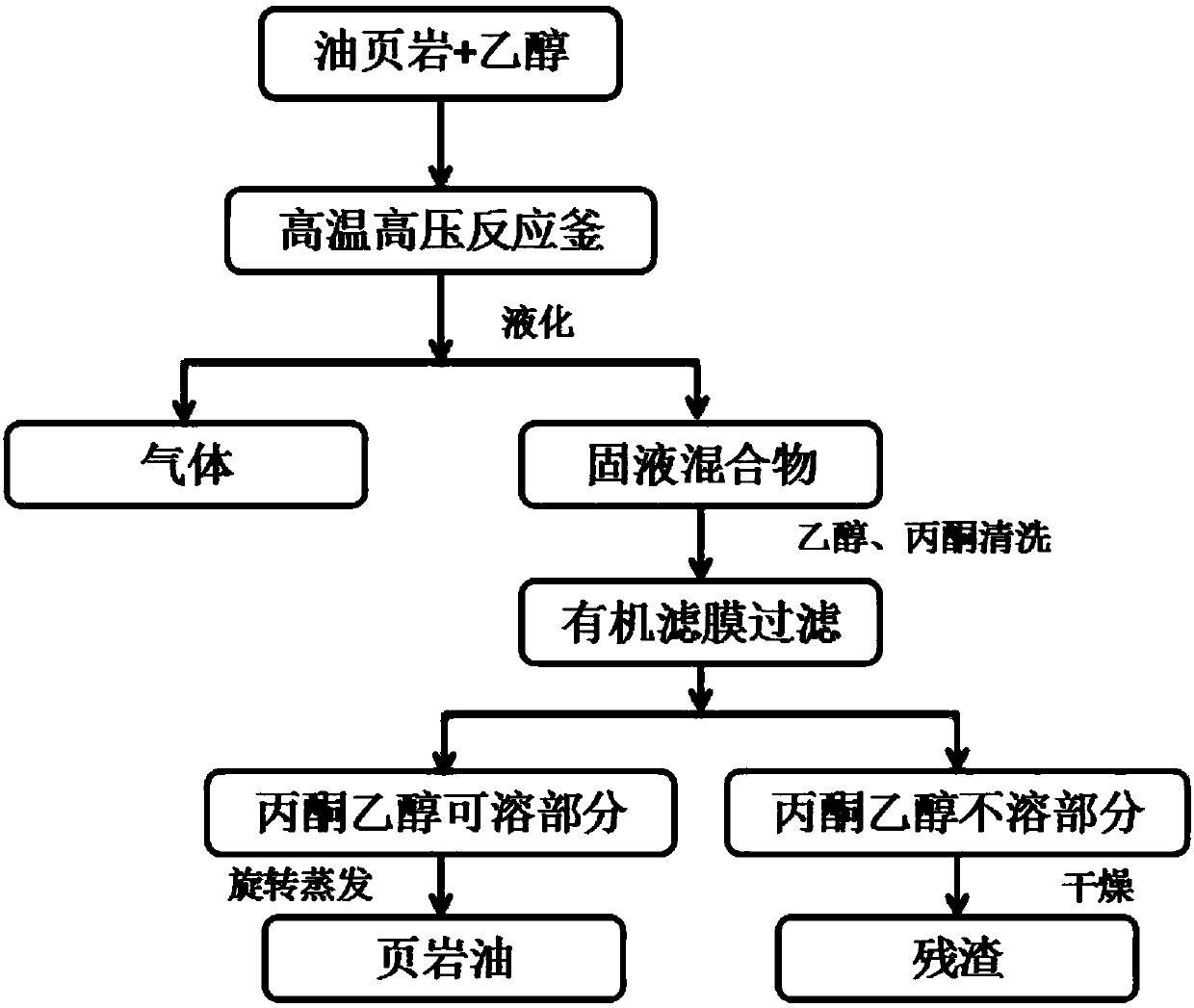

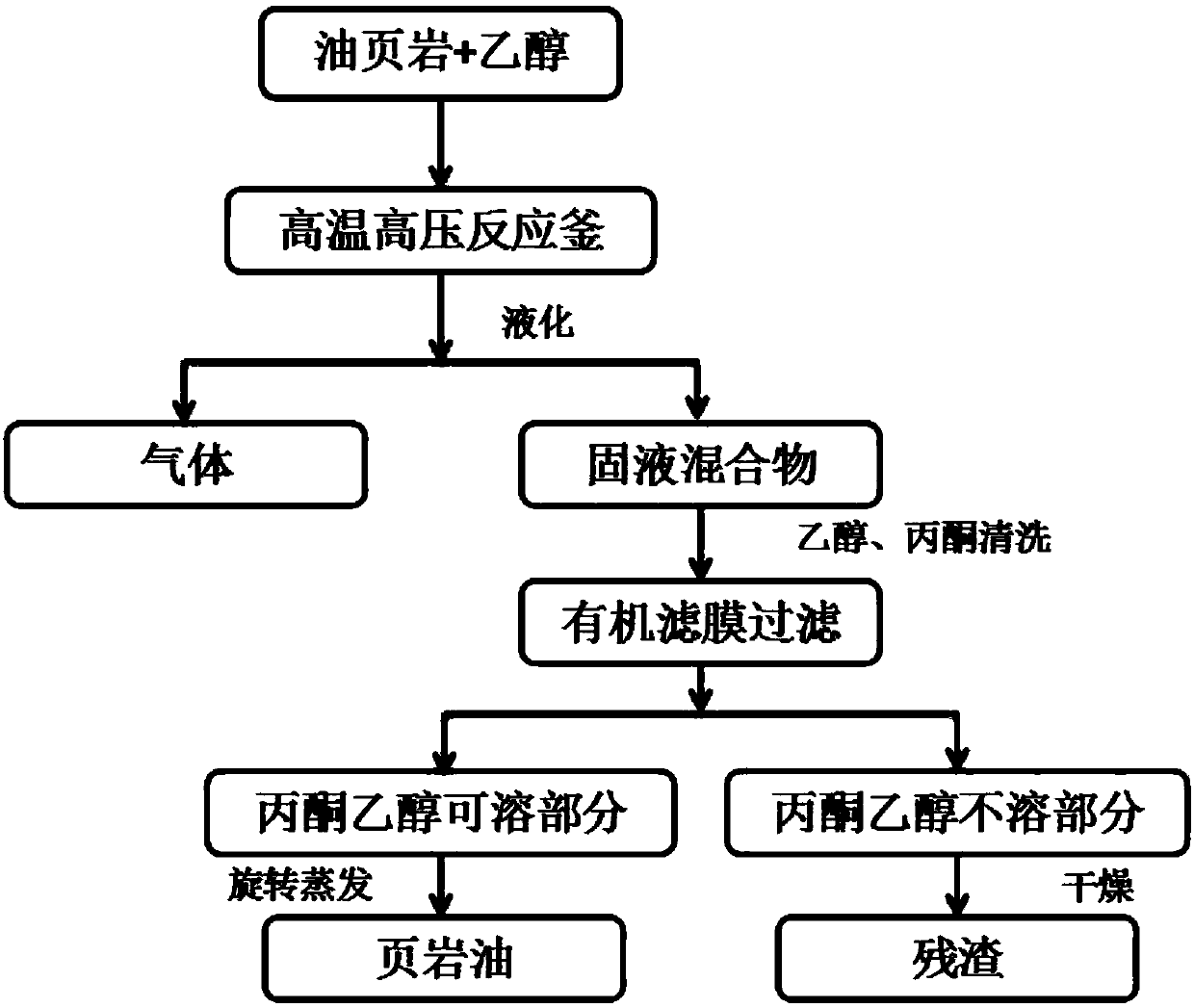

Image

Examples

Embodiment 1

[0019] Example 1: First add 20g of oil shale powder and 200ml of ethanol into a clean intermittent high-temperature and high-pressure reactor, then stir evenly with a glass rod, then seal the reactor, replace the air in the reactor with high-purity nitrogen, and turn on the power Heat the reactor at a heating rate of 4-5.5°C / min, the temperature is heated to 280°C, the reaction time is 30min, the pressure is 5MPa, and the ethanol solvent is kept in a sub / supercritical state during the liquefaction reaction, and then after the reaction, Remove the jacket and use a fan to cool the reactor. When it cools down to about 30°C, open the exhaust valve and collect the gas by drainage. Then open the reactor, pour out the mixture of oil and residue, and clean the inner wall of the reactor with organic solvents. and the pipeline in the still to obtain the organic liquid and the residue mixture. Finally, the above mixture is filtered through an organic filter membrane and extracted with ace...

Embodiment 2

[0020] Embodiment two: basic steps are identical with embodiment, wherein when heating in reactor, temperature is heated to 320 ℃, and reaction time is 30min, and pressure is at 20MPa, and the oil production rate under this condition is 3.42%.

Embodiment 3

[0021] Embodiment three: basic steps are identical with embodiment, wherein when heating in reactor, temperature is heated to 360 ℃, and reaction time is 210min, and pressure is at 30MPa, and the oil production rate under this condition is 18.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com