A kind of graphene-copper composite fiber and preparation method thereof

A graphene fiber and composite fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as weak adhesion, and achieve the effects of less time-consuming and energy-consuming, simple preparation process, and dense fiber structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

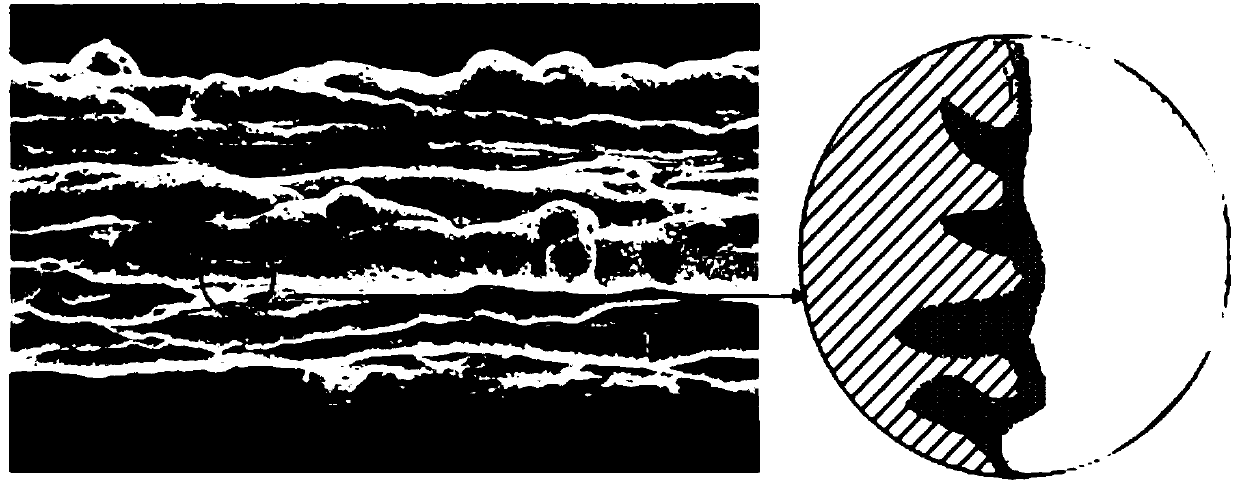

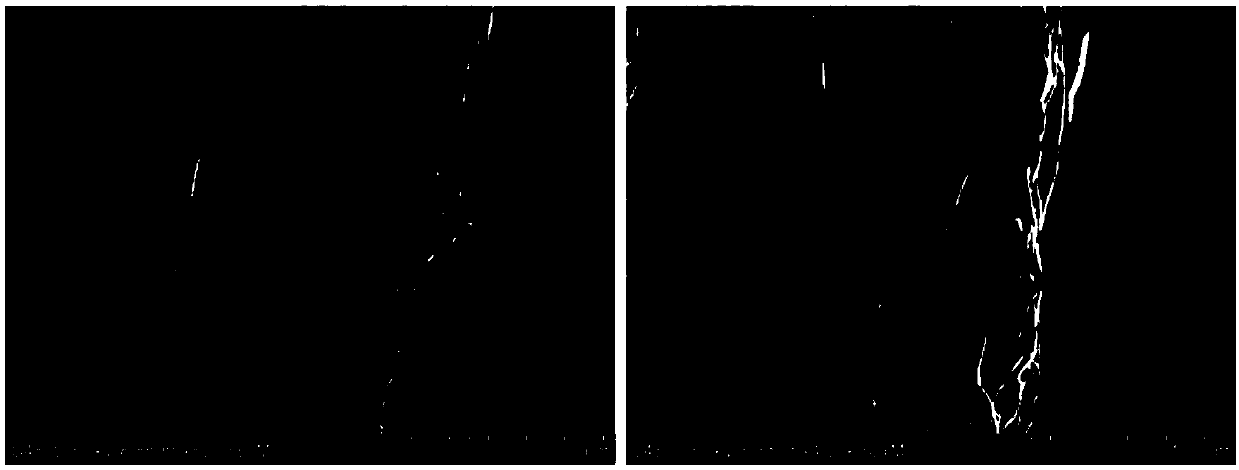

Image

Examples

Embodiment 1

[0025] A kind of electroplating method prepares the method for graphene and copper composite fiber, comprises following process:

[0026] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 5 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 5 microns (Carbon Valley Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 10mg / mL; The inner diameter of spinning head is 100 microns; : 1), the external heating temperature when receiving the wire is 200 ℃.

[0027] (2) Place the graphene oxide fiber in a high-temperature furnace for heating and reduction at a temperature of 800° C. After heating for 1.5 hours, a graphene fiber with a diameter of 5 microns is obtained.

[0028] (3) Graphene fiber is fixed on the negative pole of electroplating tank and carries out electroplating, and electroplating tank positive pole is high-purity copper bar, applies t...

Embodiment 2

[0030] A kind of electroplating method prepares the method for graphene and copper composite fiber, comprises following process,

[0031] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 10 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 5 microns (Carbon Gu Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 8mg / mL; The internal diameter of spinning head is 250 microns; Coagulation bath is the mixed solution of ethyl acetate and dichloromethane (both volume ratios are 10 : 1), the external heating temperature when receiving wire is 80 ℃.

[0032] (2) Place the graphene oxide fiber in a high-temperature furnace to heat and reduce it at a temperature of 2200° C. After heating for 3 hours, a graphene fiber with a diameter of 10 microns is obtained;

[0033] (3) Graphene fiber is fixed on the negative pole of electroplating tank and carries o...

Embodiment 3

[0035] A kind of electroplating method prepares the method for graphene and copper composite fiber, comprises following process:

[0036] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 30 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 50 microns (Carbon Valley Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 11mg / mL; The inner diameter of spinning head is 500 microns; The coagulation bath is the mixed solution of ethyl acetate and dichloromethane (both volume ratios are 200 : 1), the external heating temperature when receiving wire is 100 ℃.

[0037] (2) Put the graphene oxide fiber in a high-temperature furnace for heating and reduction at a temperature of 3000° C. After heating for 1 hour, a graphene fiber with a diameter of 30 microns is obtained.

[0038] (3) Graphene fiber is fixed on the negative pole of electroplating tank and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com