Bone cement and preparation method thereof

A technology of bone cement and tricalcium phosphate, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of hindering bone replacement, slow degradation rate, slow degradation of calcium phosphate bone cement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A bone cement prepared from the following ingredients in parts by weight: 25 parts of hydroxyapatite, 0.8 part of α-tricalcium phosphate, 0.8 part of β-tricalcium phosphate, 7.5 parts of ε-polylysine, and 2 parts of coral powder 10 parts of high-chain cross-linked carboxymethyl starch, 1.5 parts of alanine modified polylactic acid, 1.5 parts of collagen, 5.5 parts of glucose, 3.5 parts of sodium carboxymethyl cellulose, 6 parts of sodium polyphosphate, 55 parts of water .

[0017] The preparation method of the above bone cement is as follows: (1) dissolve the glucose in water, and stir the prepared glucose solution for 40 minutes at a speed of 120r / min; (2) heat the glucose solution to 50°C, and then add sodium carboxymethyl cellulose (3) Modified hydroxyapatite, α-tricalcium phosphate, β-tricalcium phosphate, ε-polylysine, coral powder, high-chain cross-linked carboxymethyl starch, and alanine The polylactic acid, collagen, sodium polyphosphate and the curing solution...

Embodiment 2

[0019] A bone cement prepared from the following components by weight: 10 parts of hydroxyapatite, 8 parts of α-tricalcium phosphate, 8 parts of β-tricalcium phosphate, 1.8 parts of ε-polylysine, and 10 parts of coral powder 5 parts of high-chain cross-linked carboxymethyl starch, 5 parts of alanine modified polylactic acid, 0.5 parts of collagen, 1.5 parts of glucose, 0.8 parts of sodium carboxymethyl cellulose, 1.5 parts of sodium polyphosphate, 35 parts of water .

[0020] The preparation method of the above bone cement is as follows: (1) dissolve the glucose in water, and stir the prepared glucose solution for 20 minutes at a speed of 240r / min; (2) heat the glucose solution to 30°C, and then add sodium carboxymethylcellulose (3) Modified hydroxyapatite, α-tricalcium phosphate, β-tricalcium phosphate, ε-polylysine, coral powder, high-chain cross-linked carboxymethyl starch, and alanine The polylactic acid, collagen, sodium polyphosphate and the curing solution are mixed to...

Embodiment 3

[0022] A bone cement prepared from the following ingredients in parts by weight: 15 parts of hydroxyapatite, 2 parts of α-tricalcium phosphate, 2 parts of β-tricalcium phosphate, 6.5 parts of ε-polylysine, 4 parts of coral powder 9 parts of high-chain cross-linked carboxymethyl starch, 2.5 parts of alanine modified polylactic acid, 0.8 parts of collagen, 2.5 parts of glucose, 1.5 parts of sodium carboxymethyl cellulose, 3 parts of sodium polyphosphate, 40 parts of water .

[0023] The preparation method of the above bone cement is as follows: (1) dissolve the glucose in water, and stir the prepared glucose solution for 25 minutes at a speed of 200r / min; (2) heat the glucose solution to 37°C, and then add sodium carboxymethylcellulose (3) Modified hydroxyapatite, α-tricalcium phosphate, β-tricalcium phosphate, ε-polylysine, coral powder, high-chain cross-linked carboxymethyl starch, and alanine The polylactic acid, collagen, sodium polyphosphate and the curing solution are mix...

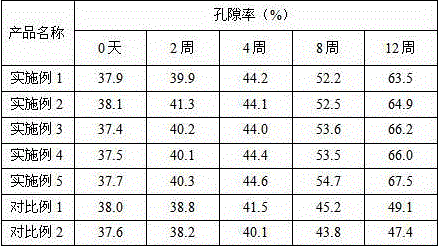

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com