Sub-region mixing type denitration system of flue gas

A flue gas and denitrification technology, applied in the field of flue gas denitrification, can solve the problems of poor uniformity of ammonia nitrogen ratio and flow field, insufficient mixing of ammonia gas and flue gas, etc., and achieve reduced concentration deviation, compact structure and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

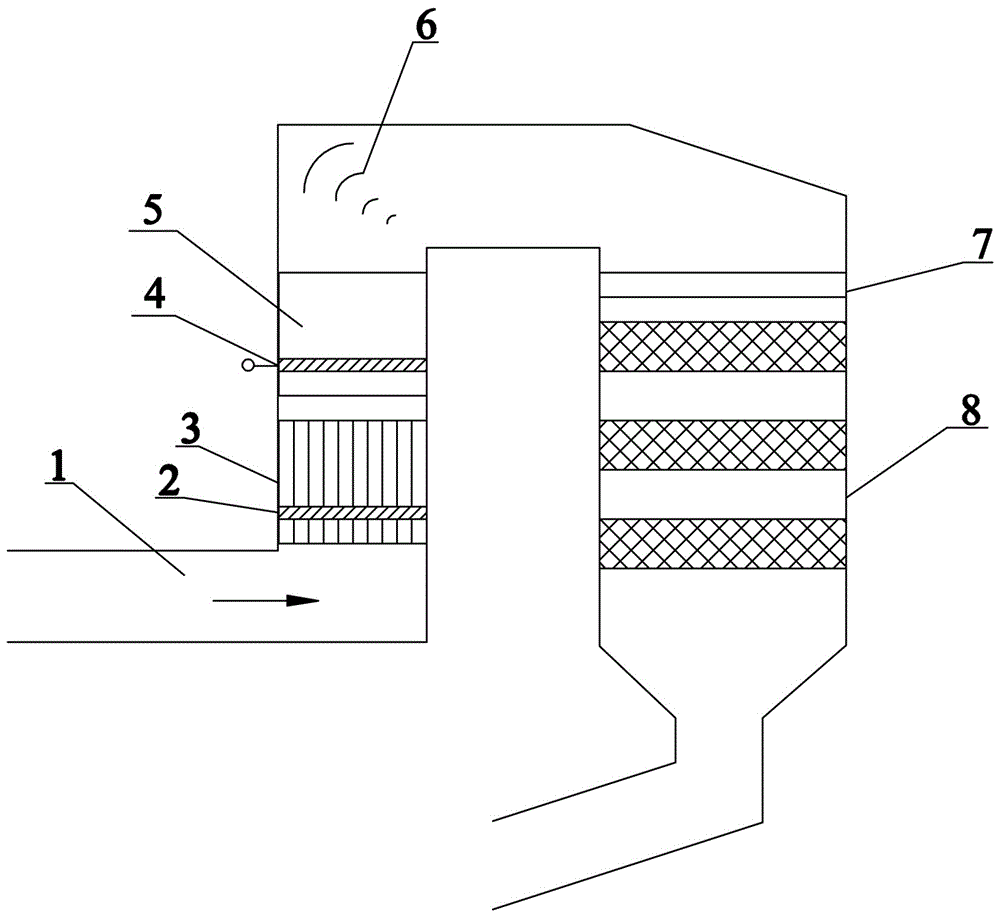

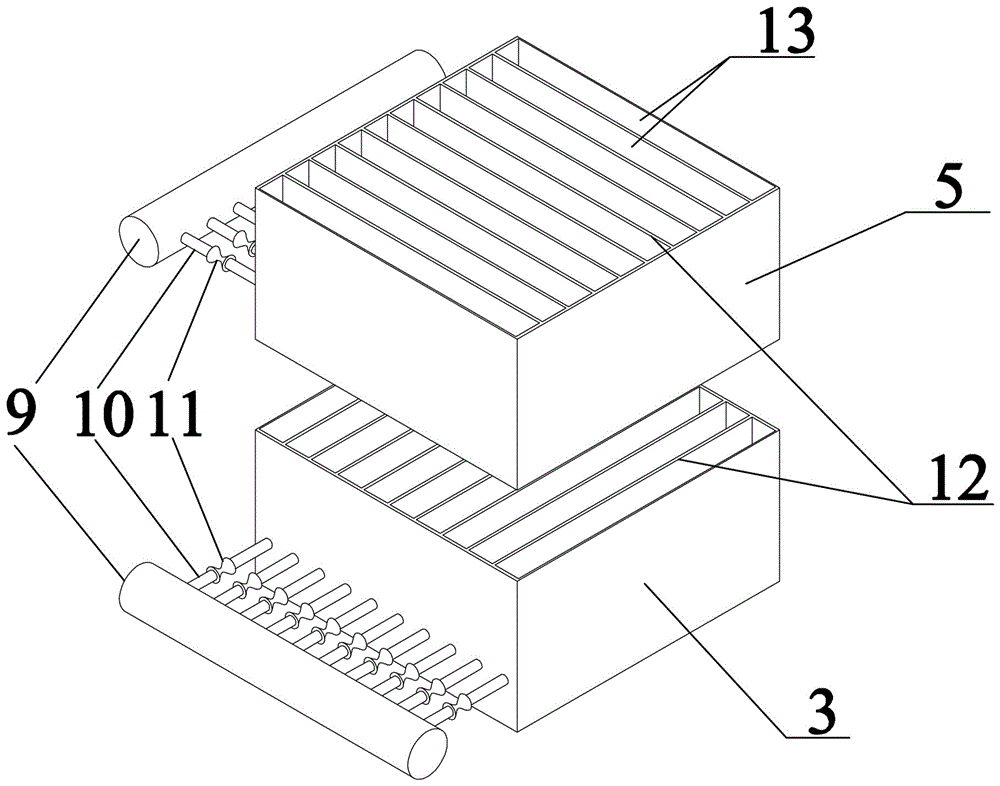

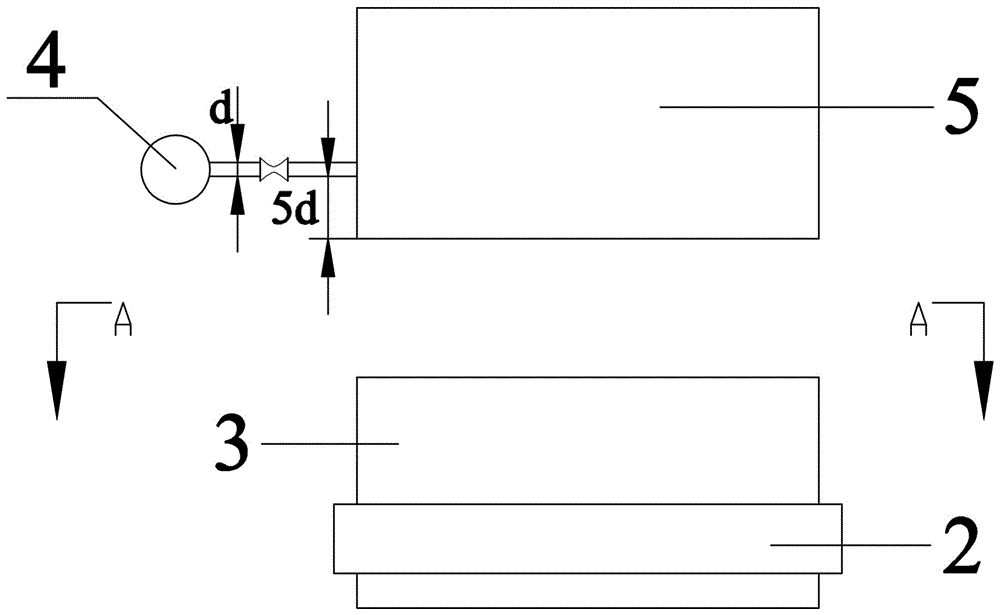

[0027] see Figure 1-4 , a flue gas zoned mixed denitrification system, comprising an SCR inlet flue 1, a first layer of ammonia injection grille 2, a first layer of clapboard partitions 3, and a second layer of ammonia injection grille 4 arranged in sequence along the direction of flue gas advancement , the second layer partition partition 5, the deflector 6, the rectification grid 7 and the SCR reactor 8, the deflector 6 is arranged at the upper corner of the SCR inlet flue 1, and the rectification grid 7 is arranged at The SCR reactor 8 inlet, the first layer partition partition 3 and the second layer partition partition 5 are arranged adjacently in front of the deflector 6 (see figure 1 ), each layer of ammonia injection grid 7 is composed of ammonia supply main pipe 9, several ammonia injection branch pipes 10 and regulating valve 11, ammonia supply main pipe 9 is connected with several ammonia injection branch pipes 10, and the starting position of each ammonia injection...

Embodiment 2

[0030] see Figure 5 , the flue gas partition mixed denitrification system of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. Some differences are: the first partition partition 3 and the second partition partition 5 are respectively located Plate 6 front and rear.

[0031] Treat a coal-fired power plant with a boiler load of 300MW and a flue gas volume of 1017000Nm by adopting the flue gas partitioned mixed denitrification system of this embodiment 3 / h, ammonia nitrogen ratio 0.80, NO in flue gas x The concentration is 400mg / Nm 3 , so that NO in flue gasx Concentration decreased to 36mg / Nm 3 The denitrification efficiency is 91%, and the ammonia escape concentration is reduced to 3ppm, meeting the requirements of the "ultra-low emission" standard for coal-fired boilers in power plants.

Embodiment 3

[0033] The mixed denitrification system for flue gas partitions in this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the distance between the branch pipe 10 of each layer of ammonia injection and the bottom end of the partition of the corresponding layer is 10 times the diameter d of the ammonia branch pipe 10.

[0034] Treat a coal-fired power plant with a boiler load of 600MW and a flue gas volume of 2,200,000Nm by using the flue gas partitioned mixed denitrification system of this embodiment 3 / h, ammonia nitrogen ratio 0.85, NO in flue gas x The concentration is 500mg / Nm 3 , so that NO in flue gas x Concentration decreased to 44mg / Nm 3 The denitrification efficiency is 91%, and the ammonia escape concentration is reduced to 3ppm, meeting the requirements of the "ultra-low emission" standard for coal-fired boilers in power plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com