Natural biomass adsorbent, and preparation method and application thereof

A technology of biomass adsorbent and adsorbent, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of complex process and low adsorption capacity, and achieve high adsorption efficiency and good hydrophilicity The effect of sex and adsorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

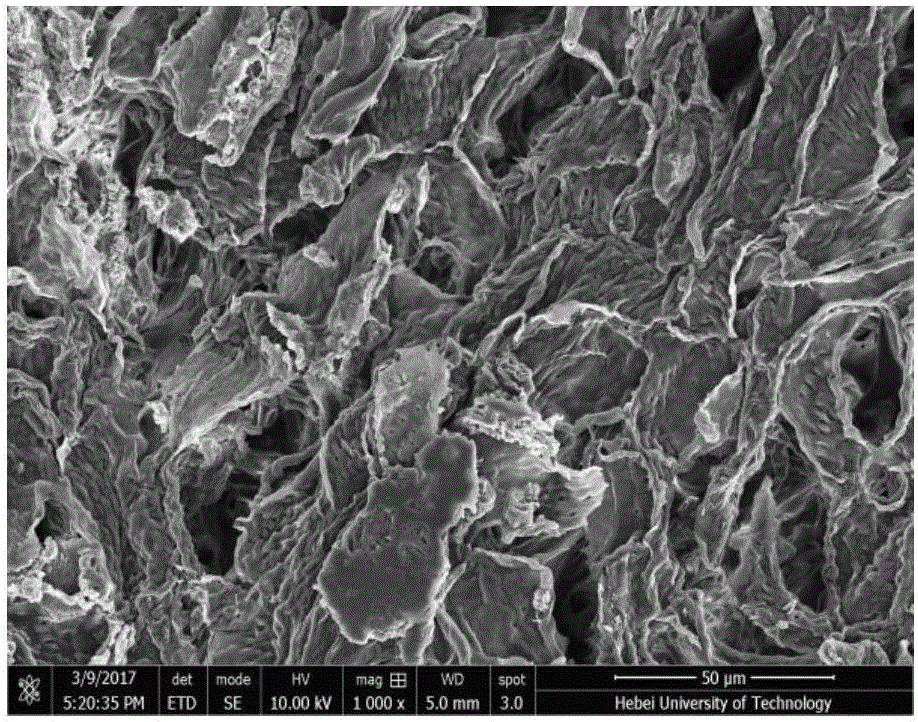

Image

Examples

Embodiment 1

[0044] (1) Preparation of peanut shell powder: clean the collected peanut shells, and then place them in an oven at 105°C to dry for 6 hours, pulverize the dried peanut shells in a grinder, and sieve them for later use to obtain a particle size of 0.06- 0.1mm peanut shell powder;

[0045] (2) Preparation of alkaline solution: Weigh 5g of sodium hydroxide, dissolve it in distilled water, dissolve completely at room temperature, transfer to a 250mL volumetric flask, dilute to the mark with distilled water, and prepare 0.5mol / L The sodium hydroxide solution is standby;

[0046] (3) Preparation of natural biomass peanut shell adsorbent: Weigh 1.5g of peanut shell powder, disperse it in 60mL of 0.5mol / L sodium hydroxide solution, transfer to 100mL autoclave and carry out water dehydration at 180°C. Heat reaction for 8 hours, after the reaction is completed, cool the autoclave to room temperature, centrifuge and wash the obtained solid product with distilled water, dry in an oven a...

Embodiment 2

[0049] (1) Preparation of peanut shell powder: clean the collected peanut shells, then place them in an oven at 105°C for 8 hours, crush the dried peanut shells in a grinder, and sieve them for later use to obtain a particle size of 0.06- 0.1mm peanut shell powder;

[0050] (2) Preparation of alkaline solution: Weigh 20g of sodium hydroxide, dissolve it in distilled water, dissolve completely at room temperature, transfer to a 250mL volumetric flask, dilute to the mark with distilled water, and prepare 2mol / L Sodium hydroxide solution is standby;

[0051] (3) Preparation of natural biomass peanut shell adsorbent: Weigh 3.6g of peanut shell powder, disperse it in 80mL of 2mol / L sodium hydroxide solution, transfer it to a 100mL autoclave for hydrothermal treatment at 160°C After the reaction was completed for 6 hours, the autoclave was cooled to room temperature, and the obtained solid product was centrifuged and washed with distilled water, dried in an oven at 100°C for 8 hour...

Embodiment 3

[0054] (1) Preparation of peanut shell powder: clean the collected peanut shells, and then place them in an oven at 105°C to dry for 10 hours, pulverize the dried peanut shells in a grinder, and sieve them for later use to obtain a particle size of 0.06- 0.1mm peanut shell powder;

[0055] (2) Preparation of alkaline solution: Weigh 50g of sodium hydroxide, dissolve it in distilled water, dissolve it completely at room temperature, transfer it to a 250mL volumetric flask, dilute to the mark with distilled water, and prepare 5mol / L Sodium hydroxide solution is standby;

[0056] (3) Preparation of natural biomass peanut shell adsorbent: Weigh 3.6g of peanut shell powder, disperse it in 80mL of 5mol / L sodium hydroxide solution, transfer it to a 100mL autoclave for hydrothermal treatment at 180°C React for 8 hours, after the reaction is completed, cool the autoclave to room temperature, centrifuge and wash the obtained solid product with distilled water, dry it in an oven at 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com