Preparation method of halloysite nanotube/nanometer titania composite material

A technology of nano-titanium dioxide and halloysite nanotubes, applied in chemical instruments and methods, alkali metal compounds, physical/chemical process catalysts, etc., can solve problems such as high cost and pollution of reaction waste liquid, and achieve low production cost and environmental protection. The effect of less pollution and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

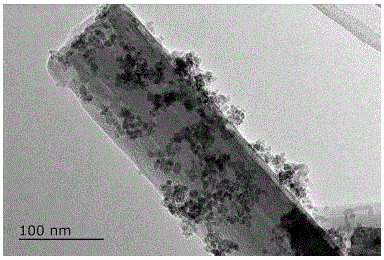

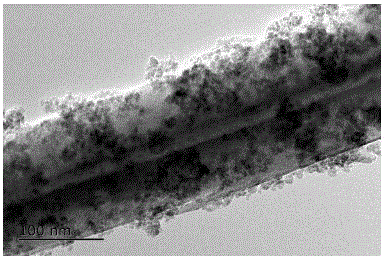

[0028] A preparation method of halloysite nanotube / nano titanium dioxide composite material. The preparation method described in this embodiment is:

[0029] Mix 15-25 parts by mass of halloysite after heat treatment, 100 parts by mass of deionized water and 1-6 parts by mass of alcohol dispersant, disperse evenly, and then add acid until 3≤pH value<7, to obtain slurry.

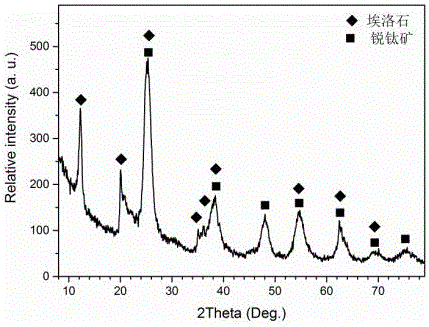

[0030] According to the mass ratio of titanium dioxide: halloysite (1~2): 10, add titanium-containing materials into the slurry, disperse evenly, and obtain mixture particles; React at 150°C for 6-10 hours; then wash with deionized water and dry to prepare the halloysite nanotube / nano-titanium dioxide composite material.

[0031] The heat-treated halloysite refers to heat-treating the halloysite at 200-400° C. for 0.5-2.5 hours to obtain the heat-treated halloysite.

[0032] The surfactant is cetyltrimethylammonium bromide.

[0033] The alcoholic dispersant is ethanol.

[0034] The titanium-containing ma...

Embodiment 2

[0037] A preparation method of halloysite nanotube / nano titanium dioxide composite material. Present embodiment except following material, all the other are with embodiment 1:

[0038] The titanium-containing material is a mixture of tetrabutyl titanate and tetraisopropyl titanate.

Embodiment 3

[0040] A preparation method of halloysite nanotube / nano titanium dioxide composite material. Present embodiment except following material, all the other are with embodiment 1:

[0041] The titanium-containing material is a mixture of tetrabutyl titanate and titanium tetrachloride.

[0042] The acid is nitric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com