Preparation method of Z-type g-C3N4@Ag@Ag3PO4 composite photocatalyst

A composite light and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of broadening the spectral response range, simple and easy control of the reaction process, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

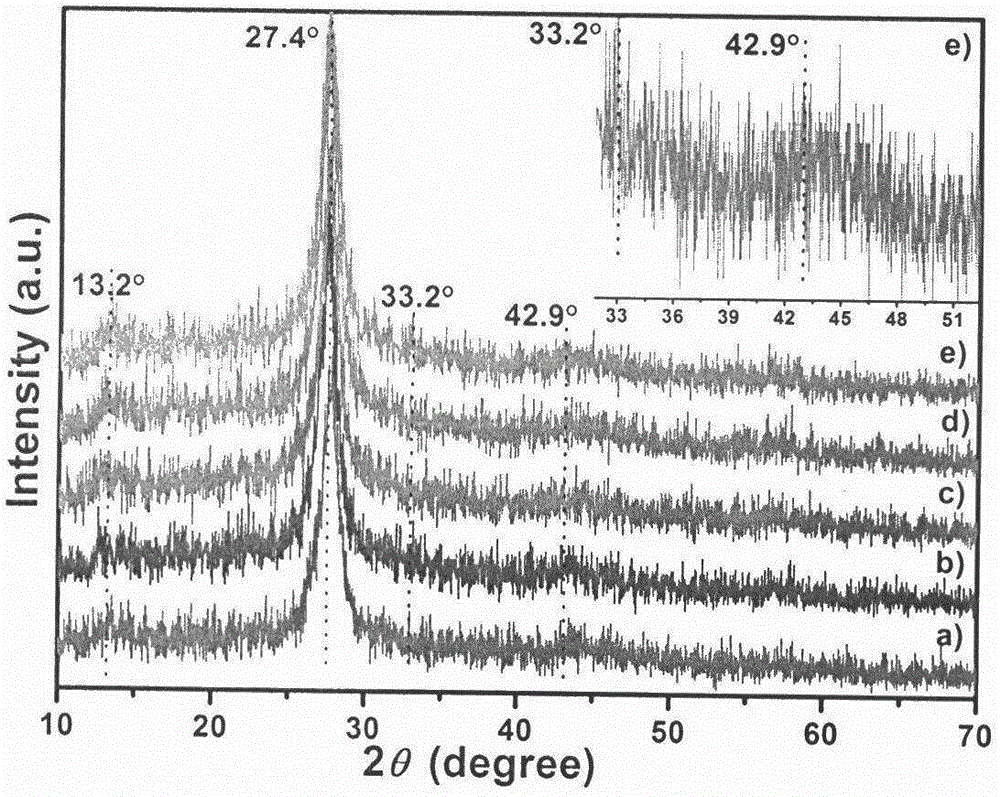

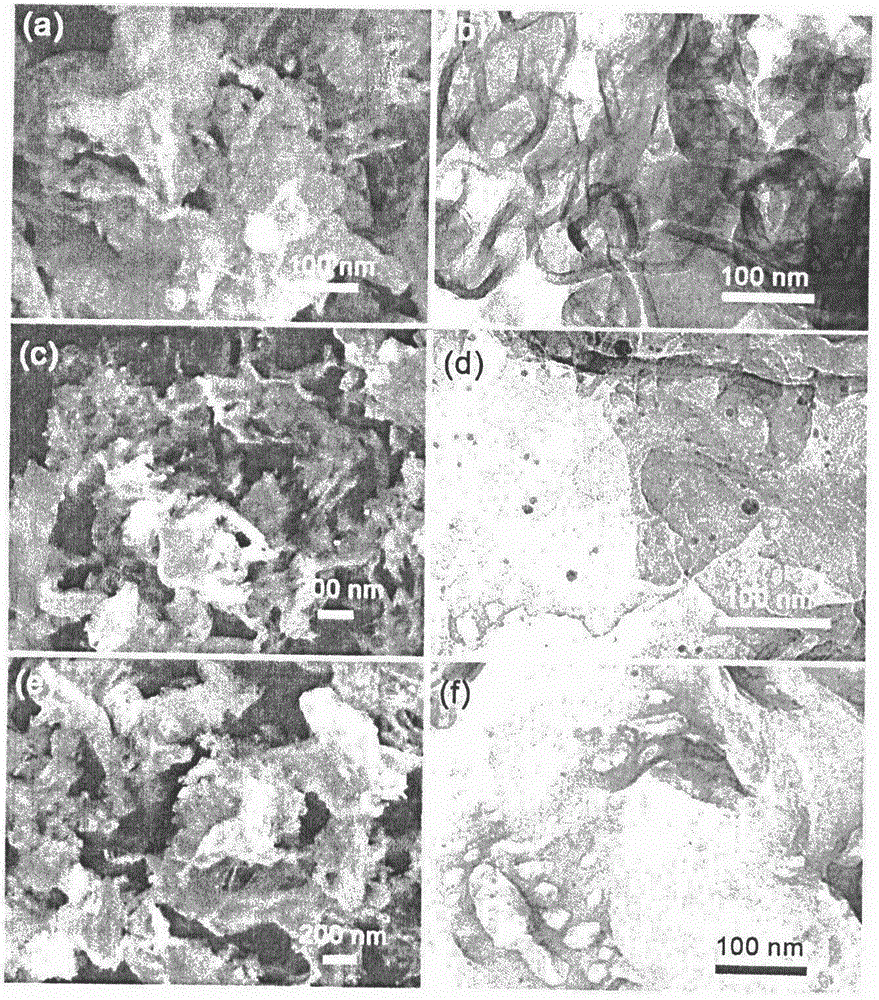

Image

Examples

Embodiment 1

[0024] (1) g-C 3 N 4 Preparation: Weigh 30g of urea in a covered ceramic crucible, place it in a muffle furnace, heat from room temperature 25°C to 400°C in an air atmosphere, keep the temperature at 400°C for 2 hours, continue heating to 550°C, and keep the temperature at 550°C 2h, naturally cooled to room temperature 25°C, and the light yellow powder obtained by grinding the sample is g-C 3 N 4 Material.

[0025] (2)g-C 3 N 4 Preparation of @Ag: Weigh 0.68g (4.0mmol) of silver nitrate and dissolve it in 50mL of deionized water, ultrasonically dissolve it for 5 minutes, and stir in a dark room for 10 minutes; weigh 40mg (1) of the obtained g-C 3 N 4Add to silver nitrate solution, disperse evenly by ultrasonication for 10min, continue to avoid light and stir at 600rpm for 1h; prepare 180g / L glucose solution, take 10mL and add to g-C 3 N 4 In a mixed solution with silver nitrate, stir and react in a water bath at 60°C in the dark for 2h; stop stirring and let stand for ...

Embodiment 2

[0031] (1) g-C 3 N 4 Preparation: Weigh 30g of urea in a covered ceramic crucible, place it in a muffle furnace, heat from room temperature 25°C to 400°C in an air atmosphere, keep the temperature at 400°C for 2 hours, continue heating to 550°C, and keep the temperature at 550°C 2h, naturally cooled to room temperature 25°C, and the light yellow powder obtained by grinding the sample is g-C 3 N 4 Material.

[0032] (2)g-C 3 N 4 Preparation of @Ag: Weigh 6mg (12wt%) silver nitrate and dissolve it in 150mL deionized water, ultrasonically dissolve for 5min, stir in dark room for 10min; weigh 44mg g-C 3 N 4 Add silver nitrate solution, disperse evenly by ultrasonication for 10min, continue to avoid light and stir at 600rpm for 1h; prepare 30g / L sodium borohydride solution, take 0.3mL and add the above g-C 3 N 4 In a mixed solution with silver nitrate, stir and react in the dark at 25°C for 1 hour; stop stirring and let it stand for 0.5 hours, then centrifuge, wash, and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com