A preparation method of monodisperse fept/fe3o4 mixed nanoparticles

A nanoparticle and monodisperse technology, applied in the nano field, can solve the problems of destroying the dispersibility of the original system, agglomeration of nanoparticles, loss of dispersion effect, etc., and achieve the effect of high utilization rate, stable particle dispersion and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A monodisperse FePt / Fe 3 o 4 A method for preparing mixed nanoparticles, comprising the following steps:

[0036] Step 1, thermal decomposition and reduction to prepare FePt nanoparticles

[0037] In Ar atmosphere, oleic acid, oleylamine, 1,2-hexadecanediol, Pt(acac) 2Add dibenzyl ether in turn, stir evenly, place in a heating furnace for preheating, the preheating temperature is 100°C, and the preheating time is 30min, then, add Fe(CO) 5 , heated to 185°C and kept for 1h to obtain FePt nanoparticles;

[0038] Among them, by volume ratio, oleic acid: oleylamine: Fe(CO) 5 : dibenzyl ether = 1: 2: 0.03: 5; molar ratio, Fe(CO) 5 : 1,2-Hexadecanediol: Pt(acac) 2 =2:1:1;

[0039] Step 2, in situ heating to prepare monodisperse FePt / Fe 3 o 4 Hybrid Nanoparticles:

[0040] (1) FePt nanoparticles are dispersed in n-hexane to obtain a n-hexane solution of FePt nanoparticles with a mass concentration of 0.5g / L;

[0041] (2) Add a n-hexane solution of FePt nanoparticles...

Embodiment 2

[0047] A monodisperse FePt / Fe 3 o 4 The preparation method of mixed nanoparticles is the same as in Example 1, the difference is that in the whole process, a magnetic field with a magnetic field strength of 6T is added to obtain monodisperse FePt / Fe 3 o 4 mixed nanoparticles;

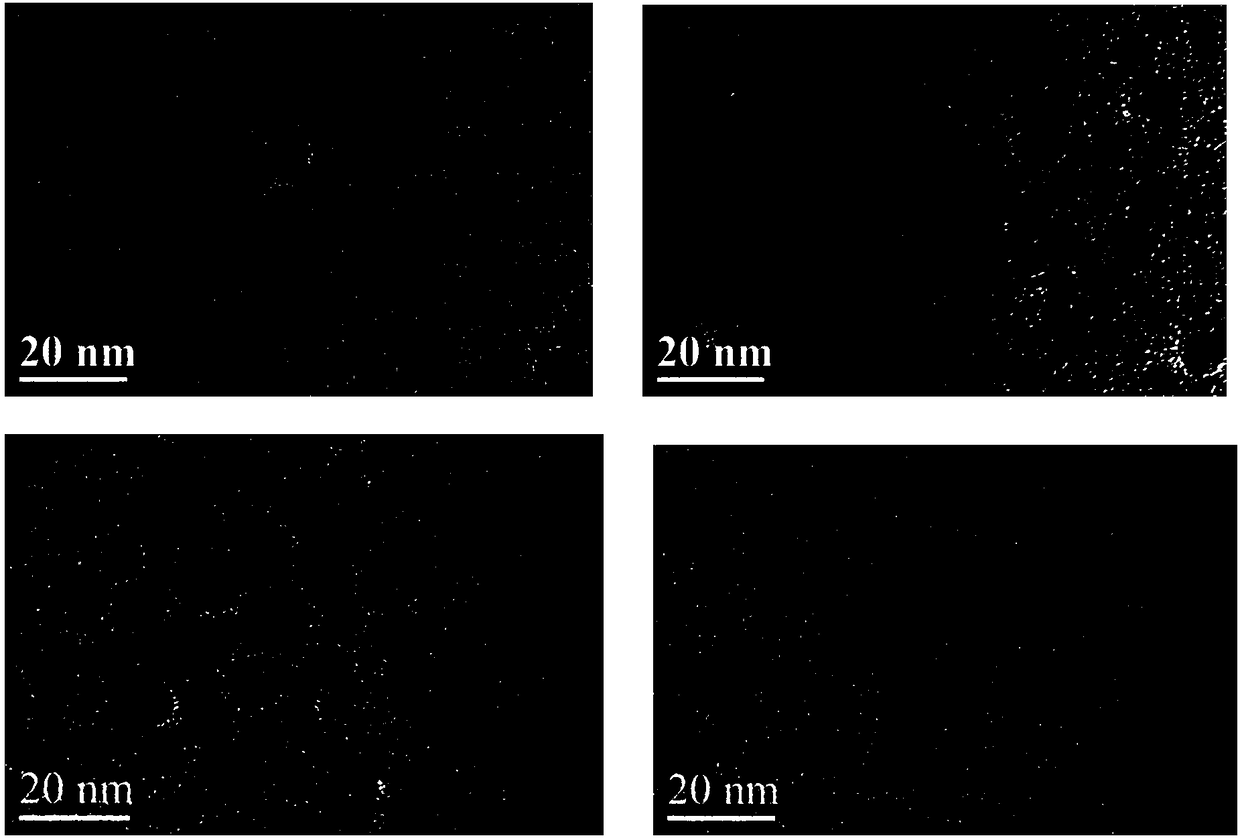

[0048] The monodisperse FePt / Fe that present embodiment makes 3 o 4 The TEM images of the mixed nanoparticles are shown in figure 1 (b), from figure 1 (b) It can be seen that under the condition of applying a strong magnetic field, FePt / Fe was successfully prepared 3 o 4 Hybrid nanoparticles, FePt nanoparticles (A) and Fe 3 o 4 The dispersion of nanoparticles (B) is still good, and the strong magnetic field does not affect the dispersion of nanoparticles.

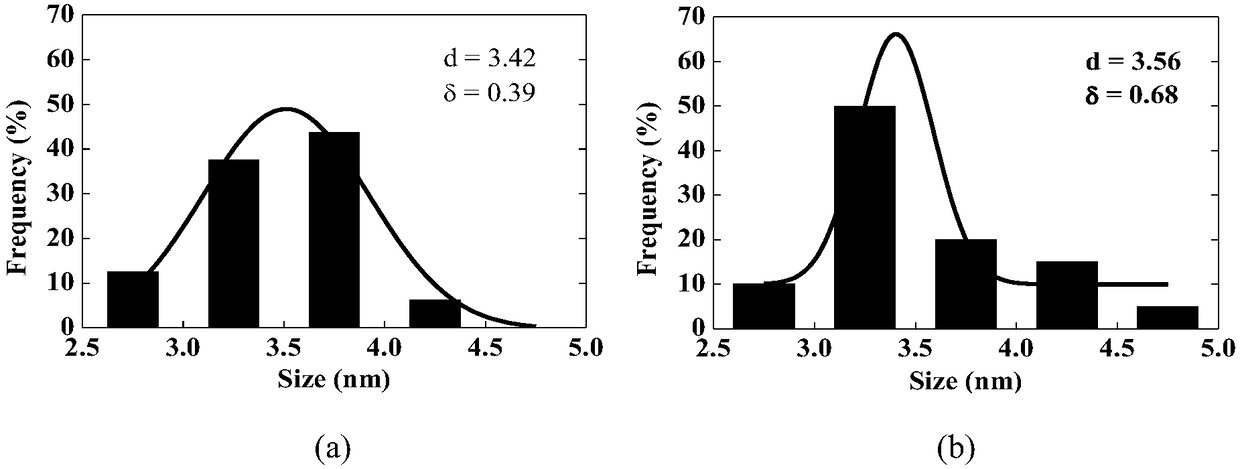

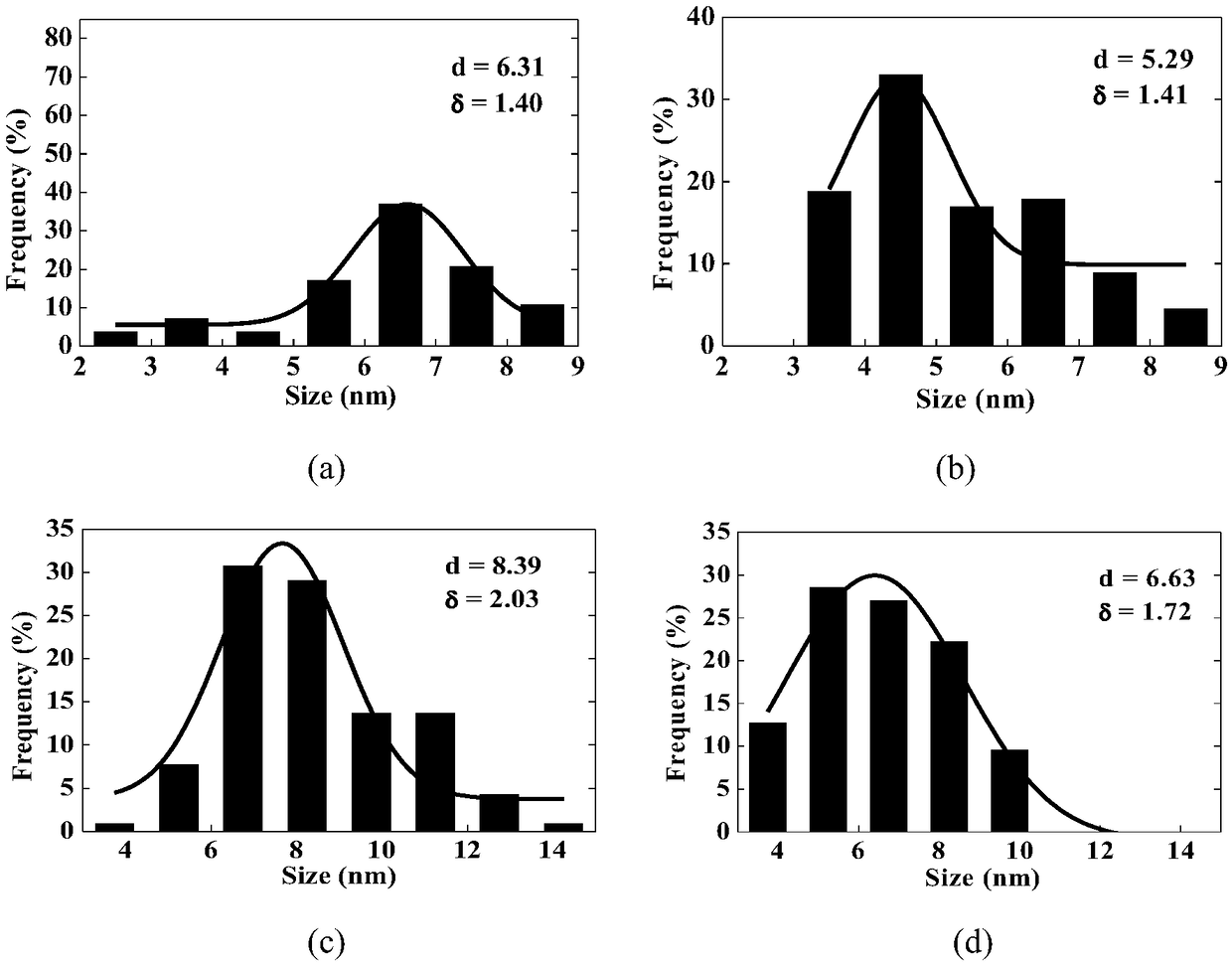

[0049] The monodisperse FePt / Fe that present embodiment makes 3 o 4 In the mixed nanoparticles, the size distribution of FePt nanoparticles is shown in Fig. 2(b), FePt 3 o 4 The size distribution diagram of the nanoparticles is shown in...

Embodiment 3

[0052] A monodisperse FePt / Fe 3 o 4 A method for preparing mixed nanoparticles, comprising the following steps:

[0053] Step 1, preparing FePt nanoparticles by thermal decomposition and reduction, same as Example 1;

[0054] Step 2, in situ heating to prepare monodisperse FePt / Fe 3 o 4 Hybrid Nanoparticles:

[0055] (1) FePt nanoparticles are dispersed in n-hexane to obtain a n-hexane solution of FePt nanoparticles with a mass concentration of 0.5g / L;

[0056] (2) In the mixed solvent of oleic acid, oleylamine, octadecene and dibenzyl ether, add the n-hexane solution of FePt nanoparticle, obtain reaction system; Wherein, by volume ratio, oleic acid: oleylamine: octadecene : dibenzyl ether=1: 1: 1: 2; the mass concentration of FePt nanoparticles in the mixed solvent is 2g / L;

[0057] The reaction system was heated to 250°C in the atmosphere, the heating rate was 5°C / min, and the temperature was kept for 1h to prepare monodisperse FePt / Fe 3 o 4 Mix nanoparticles.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com