Laser flexible micro-processing system and method based on liquid crystal spatial light modulator

A spatial light modulator and spatial light modulation technology, applied in the field of laser applications, can solve problems such as low energy utilization, low processing efficiency, and poor adaptability, achieve high adaptability and flexibility, and correct wavefront aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

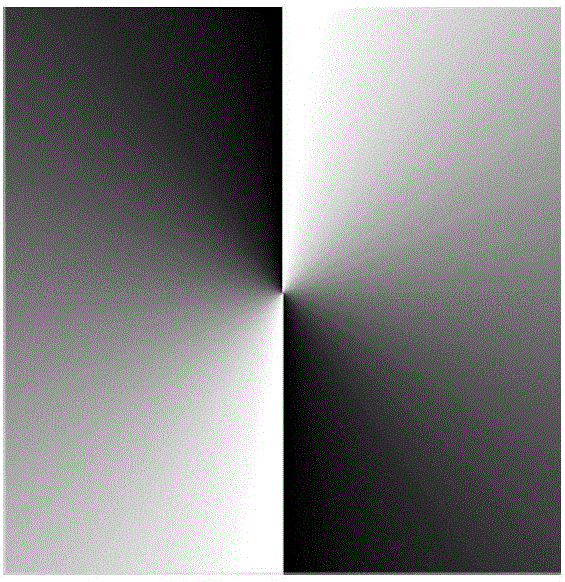

[0024] Embodiment 1: The present invention provides a laser flexible micromachining method based on a liquid crystal spatial light modulator, comprising the following steps:

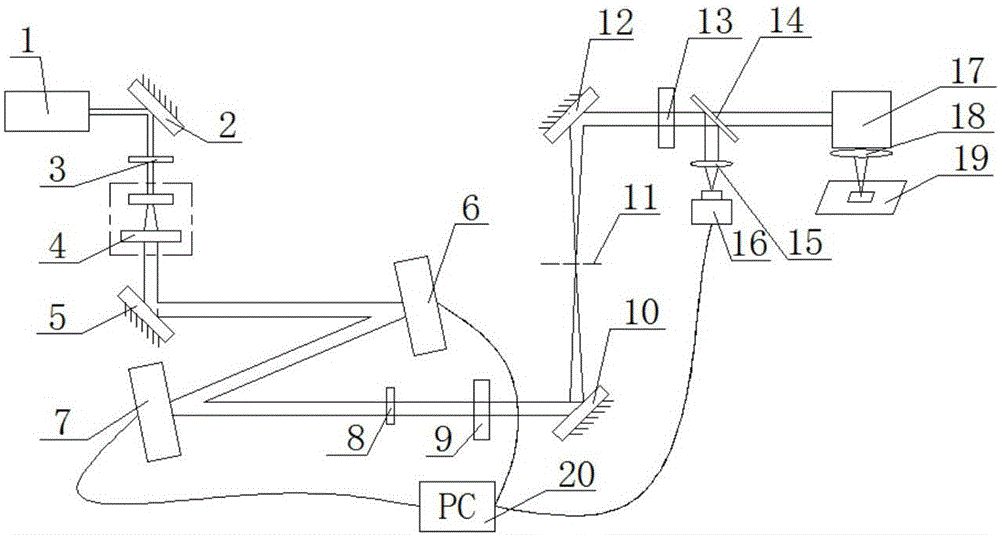

[0025] Step 1, use the superimposed GL algorithm or the iterative GS algorithm in the Labview algorithm to generate a hologram with the specified laser beam position and quantity, such as figure 2 As shown, and the hologram is loaded on the second spatial light modulation SLM7 (hereinafter referred to as "SLM7"), and the first spatial light modulation SLM6 (hereinafter referred to as "SLM6") does not load any hologram and is used as a mirror; this implementation The example Labview algorithm, SLM6 and SLM7 are controlled by computer 20, the laser beams are at any position and any number, and the hologram is generated by superposition of multiple gratings, and the hologram will also change when the position or number of beams is changed.

[0026] Step 2, inject the laser beam emitted by the laser 1 into ...

Embodiment 2

[0030] Embodiment 2: The present invention provides a laser flexible micromachining method based on a liquid crystal spatial light modulator, comprising the following steps:

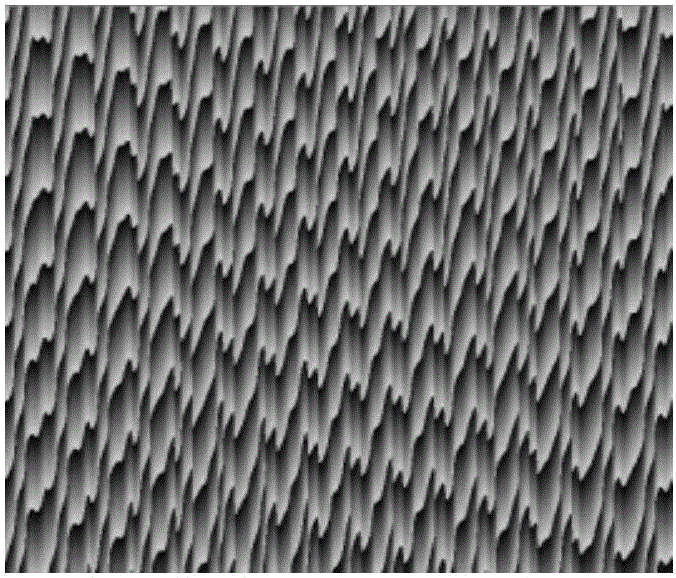

[0031]Step 1, first use the SLM control software to generate a phase hologram whose gray value varies with the polar angle, as shown in image 3 As shown, and the hologram is loaded on the SLM7, and the SLM6 does not load any hologram, which is used as a mirror; the phase hologram takes the center as the origin, and the gray value changes gradually with the change of the polar angle, and the range of the angle change is It is 0-4π.

[0032] Step 2, adjust the angles of the λ / 2 wave plate 3 and the λ / 4 wave plate 8 respectively, so that the λ / 2 wave plate 3 is 22.5° to the fast axis, and the λ / 4 wave plate 8 is -45° to the fast axis; Both the λ / 2 wave plate 3 and the λ / 4 wave plate 8 are multi-stage wave plates, the λ / 2 wave plate 3 is installed in front of the SLM7, and the λ / 4 wave plate 8 is installed...

Embodiment 3

[0036] Embodiment 3: The present invention provides a laser flexible micromachining method based on a liquid crystal spatial light modulator, comprising the following steps:

[0037] Step 1. First, use the SLM control software to generate a gray-scale mask map of the anti-Gaussian distribution and simulate the binary grating, and then use the drawing software to add the pattern that needs to be shaped into the binary grating to form a mask map, such as Figure 4 shown. The adjustment range of the grayscale of the mask image is 0-255, and at the same time, the grayscale value of the graphics in the shaping area is adjusted to 0, and the grayscale values of the binary grating are respectively 0 and 105.

[0038] Step 2, load the grayscale mask image of the inverse Gaussian distribution obtained in step 1 onto the SLM6, load the mask image containing the simulated binary grating onto the SLM7, and move the position of the mask image so that the center of the image is aligned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com