Detection device for spacial transmission pointing precision of machining light beam

A space transmission and pointing precision technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems affecting the processing quality of components, difficult to achieve high precision, poor stability, etc., achieve high degree of automation, improve precision, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

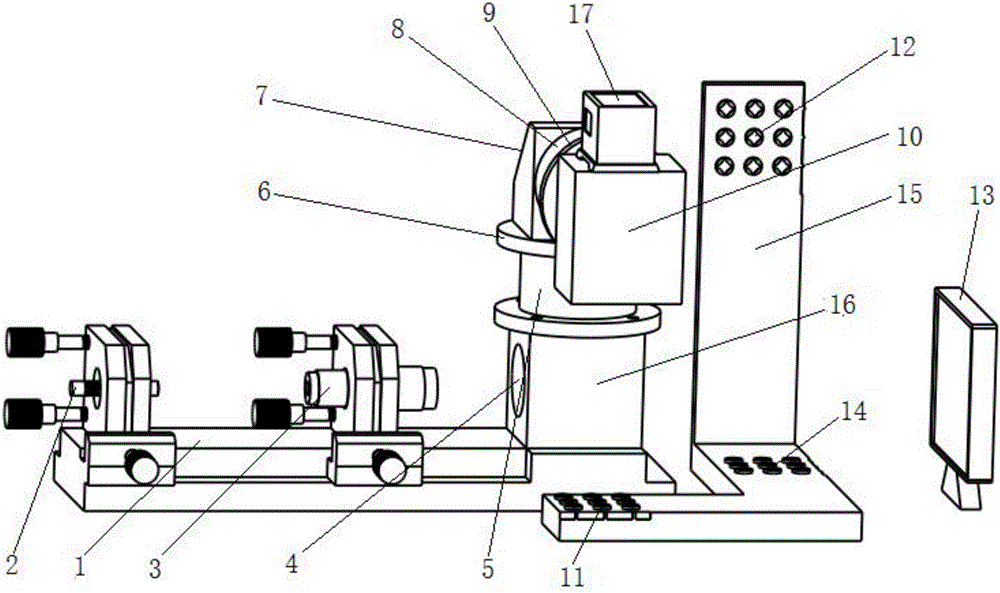

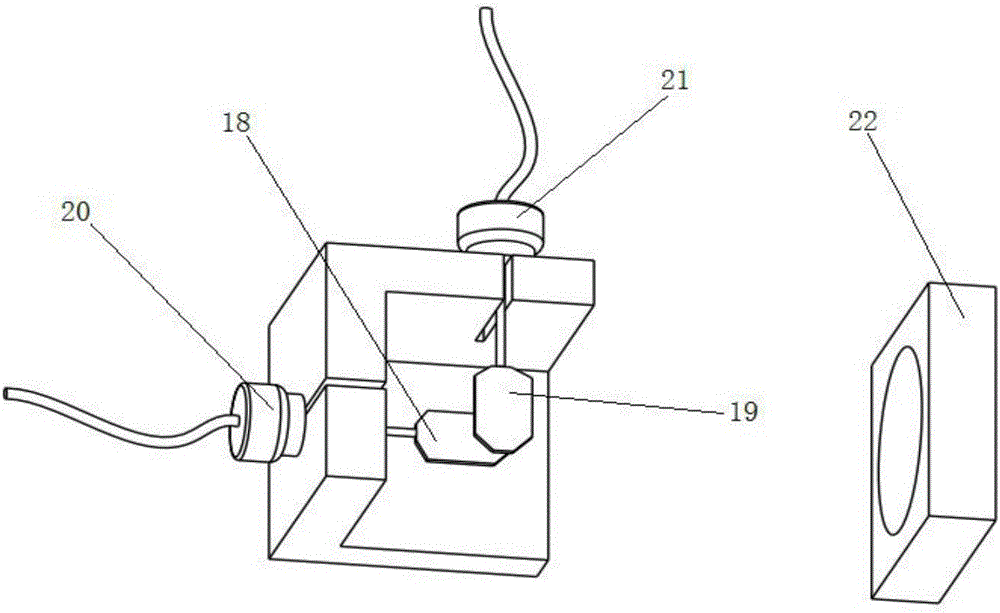

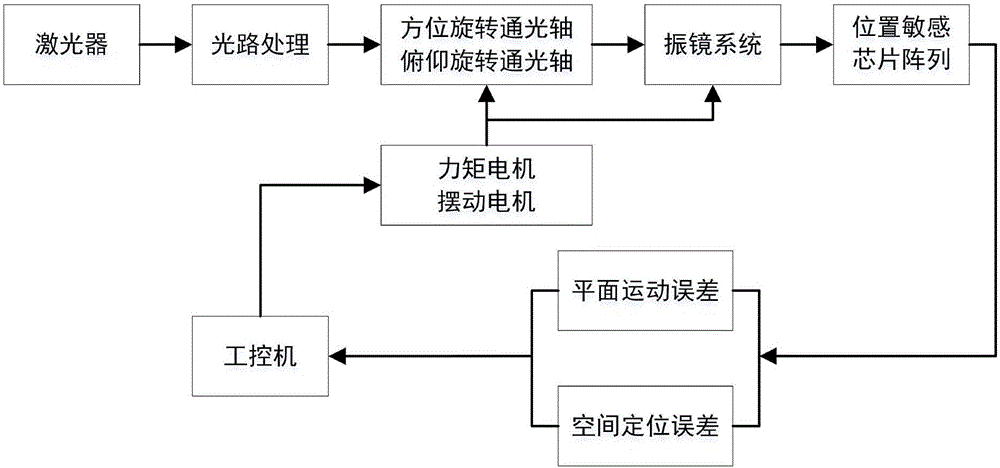

[0022] Such as figure 1 , image 3 As shown, the present invention provides a processing beam spatial transmission and pointing accuracy detection device, including a base plate 1, and also includes a laser generating part, an optical path part, a vibrating mirror system 10 and a detection part; The laser 2 used to generate laser light; the optical path part includes a beam expander 3, a reflector 4, an azimuth rotation optical axis 5, a torque motor 6, a reflector 2 7, a pitch rotation optical axis 8, and a torque motor 2. 9 and the azimuth rotation optical axis bracket 16; wherein the beam expander 3 is fixed on the base plate 1 and is located on the side of the laser beam output end of the laser 2, so as to realize the change of the diameter and divergence angle of the laser beam to improve the focusing performance; Described reflection mirror-4 is fixed on the base plate 1, and is positioned at the right side of beam expander 3, in order to realize the direction change of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap