Method for preparing hexagonal boron nitride nanometer layer sheet

A hexagonal boron nitride and nano-layer technology, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of unfavorable long-term storage and easy slow aggregation, and achieve the effect of avoiding layer aggregation and sedimentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

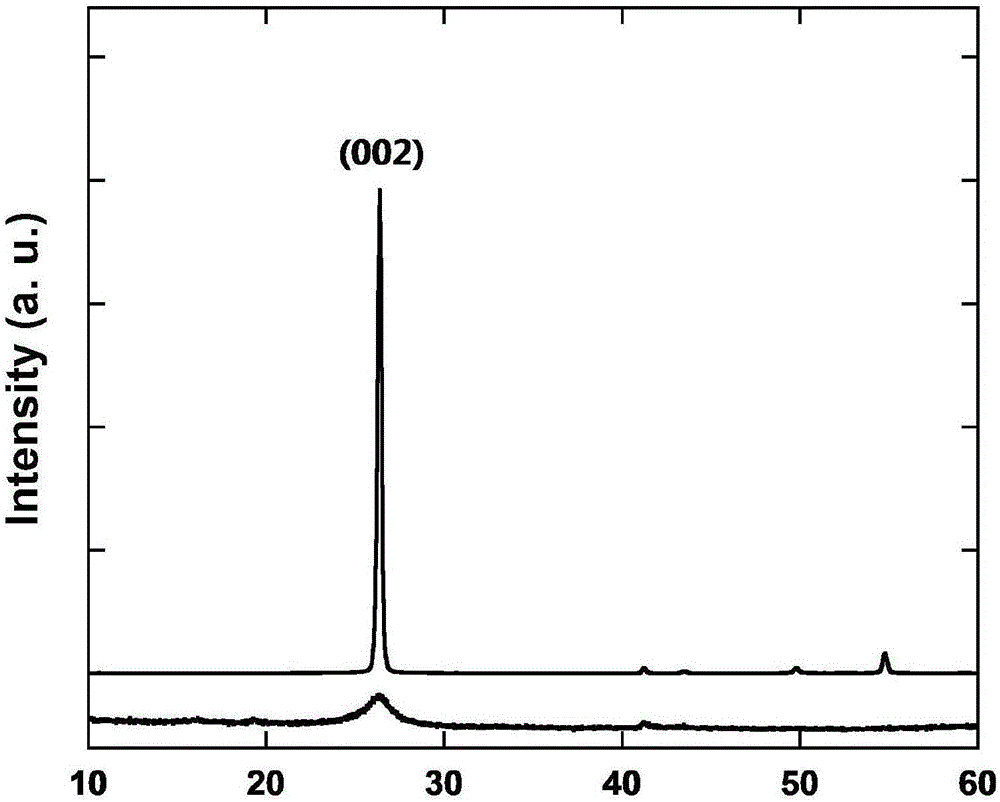

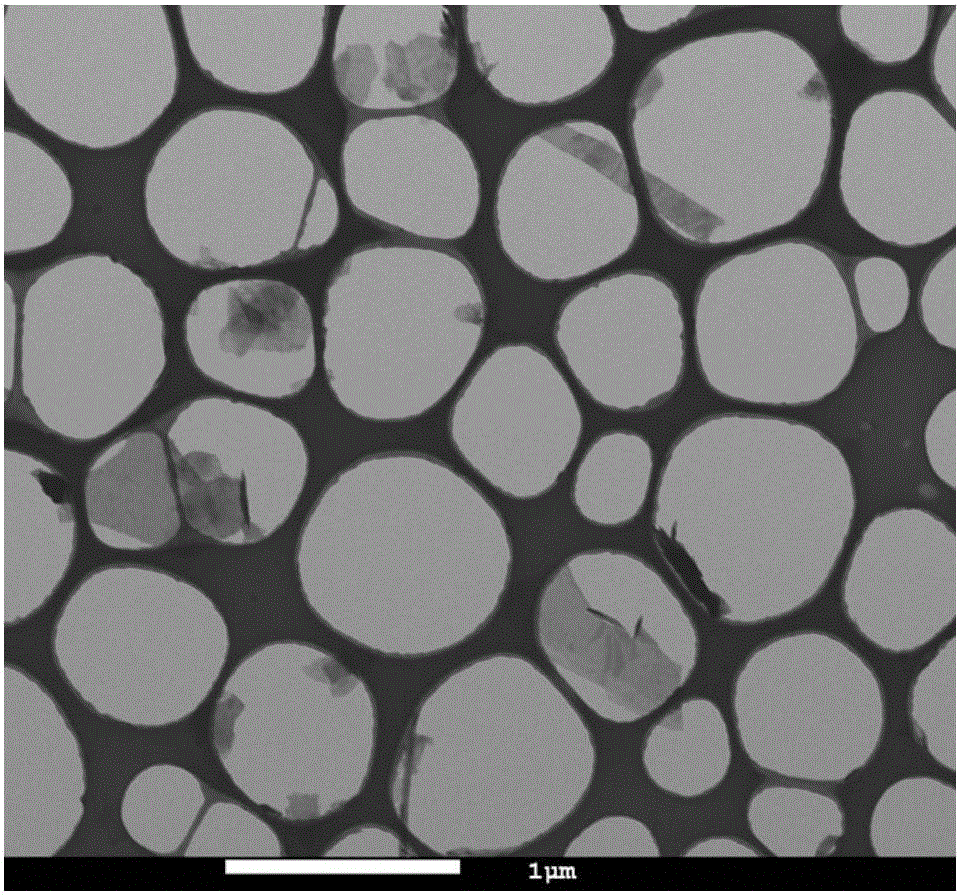

[0037] At an ambient temperature of 25°C, put 30mg of sodium cholate and 30mg of hexagonal boron nitride raw materials into a grinding jar with a volume of 45ml, then add 7 grinding balls with a diameter of 10mm, tighten the lid of the jar, and grind at a speed of 300rpm Grind for 0.5 hours. Grinding was stopped for 5 minutes to prevent temperature rise of the grind. After continuing to grind for 0.5 hour, the grinding powder is taken out to obtain the exfoliated hexagonal boron nitride nanosheet. The stripped hexagonal boron nitride nanosheets can be stored for a long time because no solvent is introduced, and can be taken and used at any time. The exfoliated hexagonal boron nitride nanosheets can be dispersed in water by shaking gently. The dispersion liquid is centrifuged under the centrifugal force of 1024g for 0.5 hour, and the nanosheets with larger thickness and size can be removed, so as to obtain hexagonal boron nitride nanosheets with narrow dimension distribution....

Embodiment 2

[0041] At an ambient temperature of 20°C, on the basis of Example 1, this example increases the amount of feed by 20 times, and the specific implementation is as follows: 1200mg sodium cholate and 600mg hexagonal boron nitride raw materials are placed in a grinding tank with a volume of 45ml , then add 7 grinding balls with a diameter of 10 mm, tighten the jar lid, and grind at a speed of 300 rpm for 0.5 hour, then stop grinding for 5 minutes to prevent the temperature of the ground material from rising. Repeat the above grinding (0.5 hour), stop (5 minutes) process until the grinding time reaches 6 hours. The grinding powder is taken out to obtain the exfoliated hexagonal boron nitride nanosheets. The stripped hexagonal boron nitride nanosheets can be stored for a long time because no solvent is introduced, and can be taken and used at any time. The exfoliated hexagonal boron nitride nanosheets can be dispersed in water by shaking gently. The dispersion liquid is centrifuge...

Embodiment 3

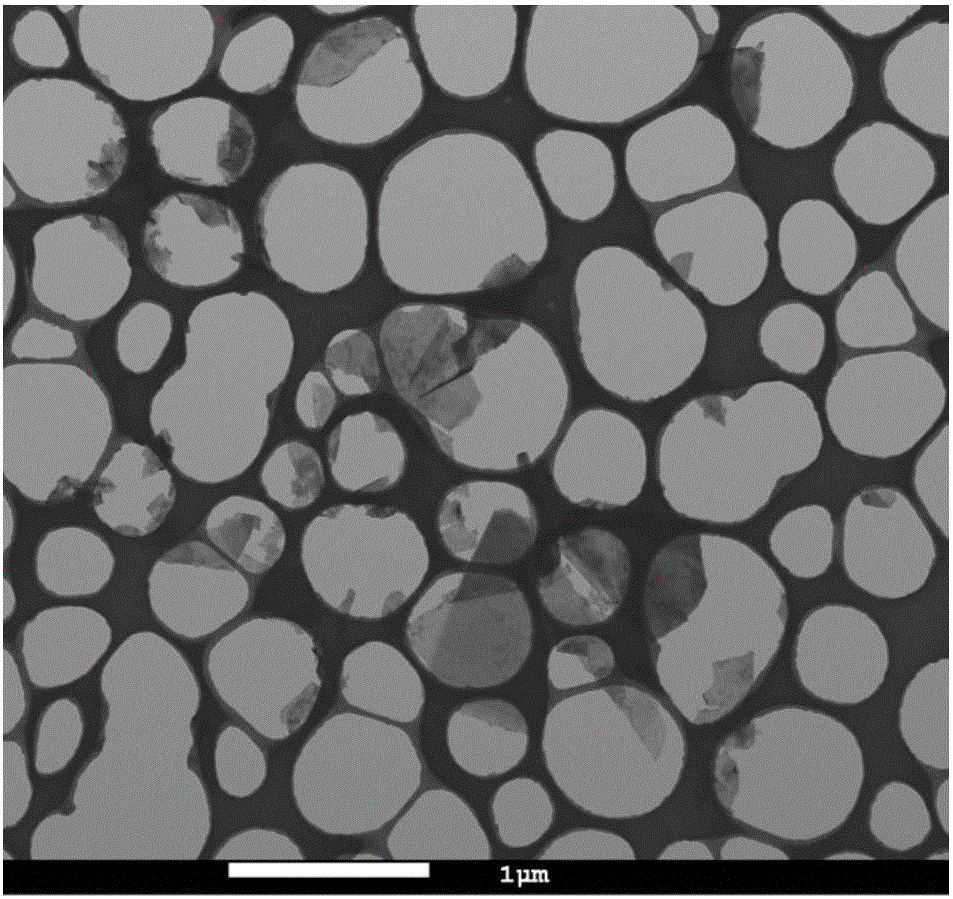

[0044] At an ambient temperature of 25°C, 30 mg of sodium dodecylbenzenesulfonate and 60 mg of hexagonal boron nitride raw materials are placed in a grinding tank with a volume of 45 ml, then 6 grinding balls with a diameter of 16 mm are added, and the tank cover is tightened. Grind at 400 rpm for 0.5 hour. Grinding was stopped for 5 minutes to prevent temperature rise of the grind. Repeat the process of grinding (0.5 hour) and stopping (5 minutes) until the grinding reaches 10 hours, then take out the grinding powder to obtain the exfoliated hexagonal boron nitride nanosheet. The stripped hexagonal boron nitride nanosheets can be stored for a long time because no solvent is introduced, and can be taken and used at any time. The exfoliated hexagonal boron nitride nanosheets can be dispersed in water by shaking gently. The dispersion liquid is centrifuged under the centrifugal force of 5000g for 1 hour, and the nanosheets with larger thickness and size can be removed, so as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com