Compression-resisting and moisture-preserving wet-mixed mortar and preparation method thereof

A technology for wet-mixing mortar and sycamore, applied in the field of building materials, can solve problems such as loss of mortar consistency, unfavorable construction, changes in mortar performance, etc., and achieve the effect of excellent moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

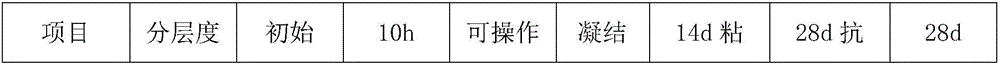

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a wet-mixed mortar that resists pressure and keeps moisture is composed of the following raw materials in terms of mass percentage: 18% cement, 8% coal gangue, 2.0% fluorogypsum, 7% volcanic rock, 30% quartz sand, Modified sycamore bark 1.3%, fly ash 4%, castor oil 0.04%, polyvinyl alcohol 0.024%, sodium polyacrylate 0.054%, the balance is water;

[0022] Wherein, the preparation steps of modified sycamore bark are:

[0023] 1) Dry the syringa bark, superfinely pulverize it into 15 μm sycamore bark powder, and set aside;

[0024] 2) immerse the plane bark powder in 35% sodium hydroxide solution with a mass concentration 4 times its mass for 2 hours;

[0025] 3) Then add silicic acid of 1.5 times the quality of the plane bark powder, and treat it with a microwave with a power of 180W for 3 minutes to obtain a mixed solution;

[0026] 4) Fill the mixture with nitrogen to fully remove oxygen, then add ferric nitrate nonahydrate...

Embodiment 2

[0032] In the embodiment of the present invention, a wet-mixed mortar that resists pressure and keeps moisture is composed of the following raw materials in terms of mass percentage: 22% cement, 6% coal gangue, 3.5% fluorogypsum, 5% volcanic rock, 34% quartz sand, Modified plane bark 1.1%, fly ash 7%, castor oil 0.03%, polyvinyl alcohol 0.027%, sodium polyacrylate 0.050%, the balance is water;

[0033] Wherein, the preparation steps of modified sycamore bark are:

[0034] 1) Dry the sycamore bark and superfinely pulverize it into 18 μm sycamore bark powder for subsequent use;

[0035] 2) immerse the plane bark powder in 32% sodium hydroxide solution with a mass concentration 5 times of its mass for 3 hours;

[0036] 3) Then add silicic acid of 1.8 times the quality of the plane bark powder, and treat it with a microwave with a power of 160W for 5 minutes to obtain a mixed solution;

[0037] 4) Fill the mixture with nitrogen to fully remove oxygen, then add ferric nitrate non...

Embodiment 3

[0043] In the embodiment of the present invention, a wet-mixed mortar that resists pressure and keeps moisture, is composed of the following raw materials in terms of mass percentage: 19% cement, 7.4% coal gangue, 2.6% fluorogypsum, 6.0% volcanic rock, 32% quartz sand, Modified sycamore bark 1.24%, fly ash 5%, castor oil 0.037%, polyvinyl alcohol 0.025%, sodium polyacrylate 0.053%, and the balance is water;

[0044] Wherein, the preparation steps of modified sycamore bark are:

[0045] 1) Dry the syringa bark, superfinely pulverize it into 15 μm sycamore bark powder, and set aside;

[0046] 2) immerse the plane bark powder in 35% sodium hydroxide solution with a mass concentration 4 times its mass for 2 hours;

[0047] 3) Then add silicic acid of 1.5 times the quality of the plane bark powder, and treat it with a microwave with a power of 180W for 3 minutes to obtain a mixed solution;

[0048] 4) Fill the mixture with nitrogen to fully remove oxygen, then add ferric nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com