Shiitake mushroom culture substrate and production method of shiitake mushroom culture substrate

A cultivation substrate and shiitake mushroom technology, applied in mushroom cultivation, cultivation, plant cultivation, etc., can solve the problems of not being able to prevent diseases and insect pests well, unfavorable large-scale cultivation of shiitake mushrooms, and high cultivation costs, and achieve a significant effect of increasing production, promoting environmental protection, The effect of low cultivation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

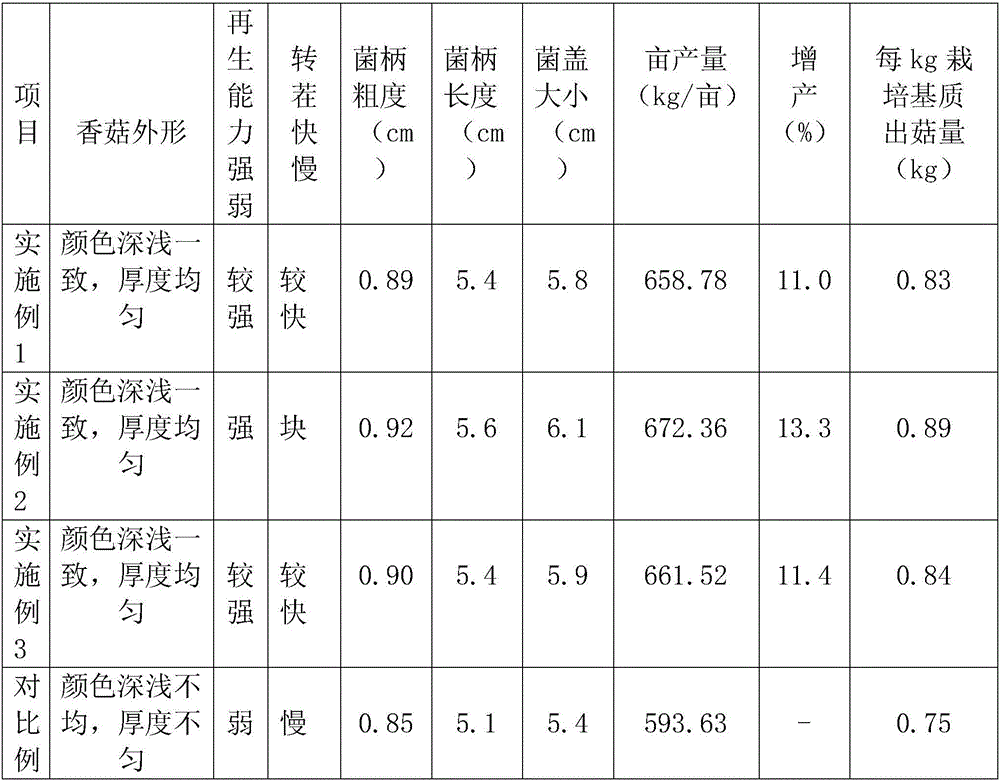

Embodiment 1

[0018] A mushroom cultivation substrate, which is composed of the following raw materials in parts by weight: 42 parts of Italian poplar sawdust, 26 parts of sweet almonds, 26 parts of corn stalks, 19 parts of lime powder, 15 parts of cotton seed husk, 3 parts of walnut leaves, 3 parts of Dendrobium candidum leaves , 0.9 parts of yeast.

[0019] The manufacturing method of the mushroom cultivation substrate includes the following specific steps:

[0020] 1) Put the sweet almonds, corn stalks and cottonseed husks into a pulverizer and pulverize them to a particle size of 6mm, and pass through a 240-mesh sieve to obtain pulverized mixture material I, which is used for later use;

[0021] 2) Put Italian poplar wood chips, walnut leaves and Dendrobium officinale leaves into the reactor and stir clockwise for 22 minutes at a stirring speed of 85r / min to obtain stirring material II, and add solution A that is 1.4 times the weight of stirring material II into it Stir evenly to obtain Mixtu...

Embodiment 2

[0024] A mushroom cultivation substrate, which is composed of the following raw materials in parts by weight: 44 parts of Italian poplar sawdust, 29 parts of sweet almonds, 27 parts of corn stalks, 20 parts of lime powder, 17 parts of cotton seed husk, 5 parts of walnut leaves, 5 parts of Dendrobium candidum leaves , 1.3 parts of yeast.

[0025] The manufacturing method of the mushroom cultivation substrate includes the following specific steps:

[0026] 1) Put sweet almonds, corn stalks and cottonseed husks into a pulverizer and pulverize to a particle size of 6.5mm, and pass through a 230-mesh sieve to obtain a pulverized mixture material I, for use;

[0027] 2) Put Italian poplar wood chips, walnut leaves and Dendrobium officinale leaves into the reactor and stir clockwise for 24 minutes at a stirring speed of 90r / min to obtain stirring material II, and add solution A that is 1.6 times the weight of stirring material II into it Stir evenly to obtain Mixture III, place it in the f...

Embodiment 3

[0030] A mushroom cultivation substrate, which is composed of the following raw materials in parts by weight: 46 parts of Italian poplar sawdust, 32 parts of sweet almonds, 28 parts of corn stalks, 21 parts of lime powder, 19 parts of cotton seed husk, 7 parts of walnut leaves, 7 parts of Dendrobium candidum leaves 1.7 parts of yeast.

[0031] The manufacturing method of the mushroom cultivation substrate includes the following specific steps:

[0032] 1) Put the sweet almonds, corn stalks and cottonseed husks into a pulverizer and pulverize to a particle size of 7mm, and pass through a 200-mesh sieve to obtain pulverized mixture material I, which is used for later use;

[0033] 2) Put Italian poplar sawdust, walnut leaves and Dendrobium officinale leaves into the reactor and stir clockwise for 26 minutes at a stirring speed of 95r / min to obtain stirring material II, and add solution A 1.8 times the weight of stirring material II to it Stir evenly to obtain Mixture III, place it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com