A kind of preparation method of methyl ionone and intermediate thereof

A technology for methyl ionone and intermediates, applied in the fields of fragrance chemistry and fine chemicals, can solve the problems of waste of alkali, cumbersome process, unspecified proportion of pseudo-isomethyl ionone, etc., and achieve cost reduction and lighten Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

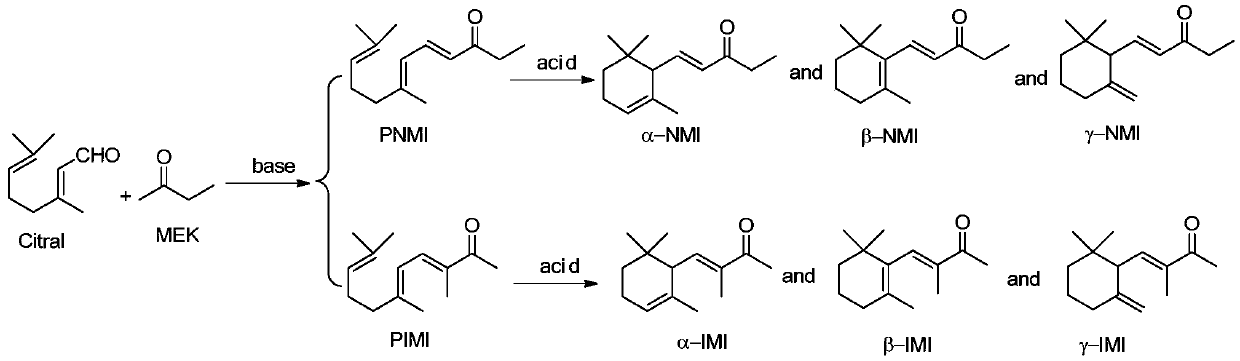

Method used

Image

Examples

Embodiment 1

[0031] In a three-necked flask with a stirring device, a thermometer and a dropping funnel, add 200g of PEG-600 and 11g of potassium hydroxide. After the dissolution is complete, add 100g of butanone, and mix the mixture of 50g of citral and 20g of butanone under stirring. Add dropwise into the reaction system for 1 hour, and the dropwise reaction temperature is 10°C. After the dropwise addition, raise the temperature to 20°C and continue the heat preservation reaction for 1 hour. Once, the n-hexane layers were combined, washed with water, washed with saturated brine, evaporated by rotary evaporation to remove the solvent, and then distilled under reduced pressure to collect fractions at 140Pa / 115-118°C to obtain a pseudomethyl ionone product with a purity of 99% and a yield of 94 %, the proportion of pseudo-isomethyl ionone is 75%.

Embodiment 2

[0033] In a three-necked flask with a stirring device, a thermometer and a dropping funnel, add 200g of PEG-200 and 11g of potassium hydroxide. After the dissolution is complete, add 100g of butanone, and mix the mixture of 50g of citral and 20g of butanone under stirring. Add dropwise into the reaction system for 1 hour, and the dropwise reaction temperature is 10°C. After the dropwise addition, raise the temperature to 20°C and continue the heat preservation reaction for 1 hour. Once, the n-hexane layers were combined, washed with water, washed with saturated brine, evaporated to remove the solvent, and distilled under reduced pressure to collect fractions at 140Pa / 115-118°C to obtain a pseudomethyl ionone product with a purity of 99% and a yield of 92 %, the proportion of pseudo-isomethyl ionone is 73%.

Embodiment 3

[0035]In a three-necked flask with a stirring device, a thermometer and a dropping funnel, add 200g of PEG-400 and 11g of potassium hydroxide. After the dissolution is complete, add 100g of butanone, and mix the mixture of 50g of citral and 20g of butanone under stirring. Add dropwise into the reaction system for 1 hour, and the dropwise reaction temperature is 10°C. After the dropwise addition, raise the temperature to 20°C and continue the heat preservation reaction for 1 hour. Once, the n-hexane layers were combined, washed with water, washed with saturated saline, evaporated to remove the solvent, and distilled under reduced pressure to collect fractions at 140Pa / 115-118°C to obtain a pseudomethyl ionone product with a purity of 99% and a yield of 93 %, the proportion of pseudo-isomethyl ionone is 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com