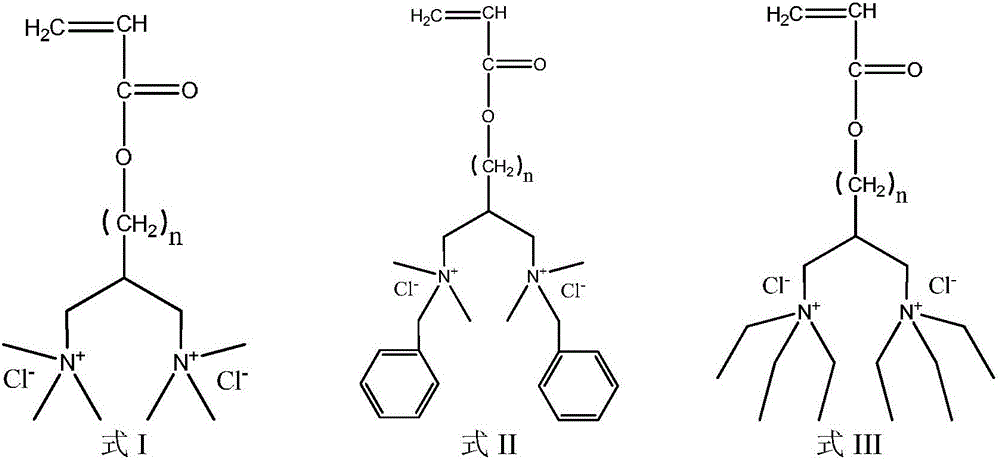

Cation polyacrylamide inverse emulsion and preparation method thereof

A polyacrylamide and inverse emulsion technology, which is applied in the field of cationic polyacrylamide inverse emulsion and its preparation, can solve the problems of product performance impact, single function, poor product stability, etc., and achieve low organic solvent consumption and solid content High, fast dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

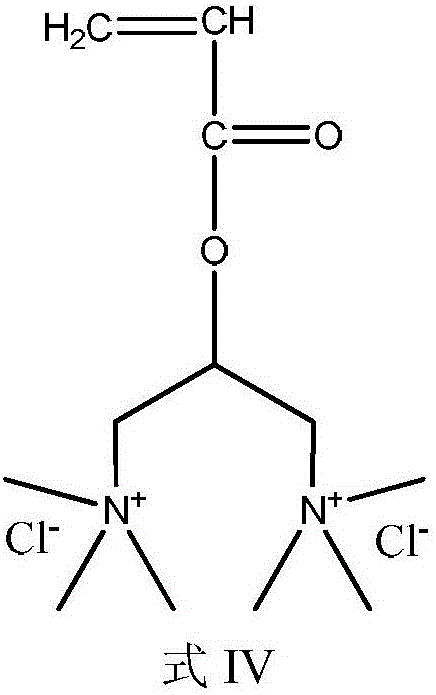

Embodiment 1

[0035] In this example, the nonionic monomer is acrylamide, the cationic monomer is acryloyloxyethyltrimethylammonium chloride, and the functional monomer is shown in formula IV, consisting of nonionic monomer, cationic monomer and functional monomer The quality of the cationic copolymer accounts for 30.2% of the total mass of the emulsion, and the molar ratio of nonionic monomer, cationic monomer and functional monomer is 8.5:1.5:0.5; emulsifier is polyoxyethylene sorbitan ether oleic acid Ester and nonylphenol polyoxyethylene ether, its consumption is 4.5% of the total mass of the emulsion; the organic solvent adopts kerosene, and its consumption is 33% of the total mass of the emulsion; 1.5%, the balance is water.

[0036]

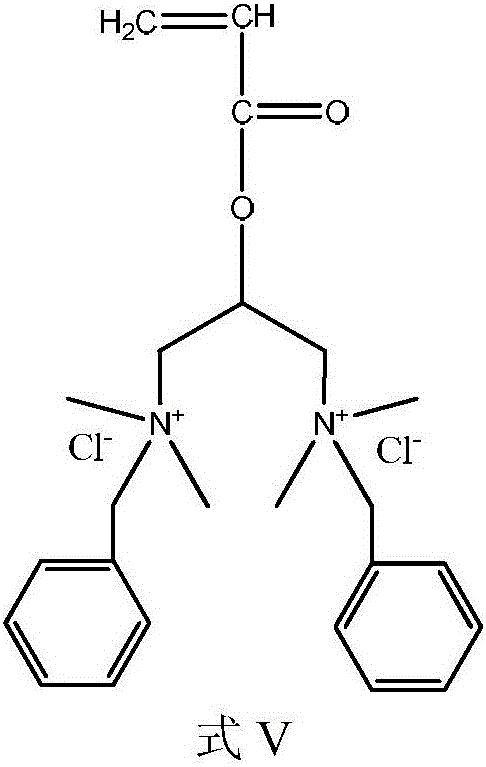

Embodiment 2

[0038] In this embodiment, the nonionic monomer is N-methacrylamide, the cationic monomer is methacryloyloxyethyltrimethylammonium chloride, and the functional monomer is shown in formula V, nonionic monomer, cationic monomer The quality of the cationic copolymer formed with functional monomer accounts for 35.2% of the total mass of the emulsion, and the molar ratio of nonionic monomer, cationic monomer and functional monomer is 7.0:2.0:0.5; emulsifier is sorbitan Polyoxyethylene ether stearate and sorbitan polyoxyethylene ether, its consumption is 5.5% of the total mass of the emulsion; the organic solvent adopts white oil, and its consumption is 30.5% of the total mass of the emulsion; the stabilizing auxiliary agent is chlorinated Sodium, its consumption is 1.2% of the total mass of the emulsion, and the balance is water.

[0039]

Embodiment 3

[0041] In this embodiment, the nonionic monomer is methacrylamide, and the cationic monomer is N, N-dimethyl diallyl ammonium chloride. The functional monomer is shown in formula VI, and the nonionic monomer, cationic monomer and The quality of the cationic copolymer that functional monomer is formed accounts for 39.8% of the total mass of the emulsion, and the molar ratio of nonionic monomer, cationic monomer and functional monomer is 5.5:4.5:1.5; Emulsifier is sorbitan poly Oxyethylene ether stearate and alkylphenol polyoxyethylene ether, its consumption is 5.0% of the total mass of the emulsion; the organic solvent adopts xylene, and its consumption is 24.5% of the total mass of the emulsion; the stabilizing auxiliary agent is ammonium chloride, Its consumption is 2.2% of the total mass of the emulsion, and the balance is water.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com