Castor oil modified emulsion for improving edge corrosion resistance of waterborne coating

A technology of water-based paint and castor oil, applied in anti-corrosion paint, coating, etc., can solve problems such as low grafting rate and unstable emulsion, achieve good compatibility, improve salt spray resistance, and increase reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

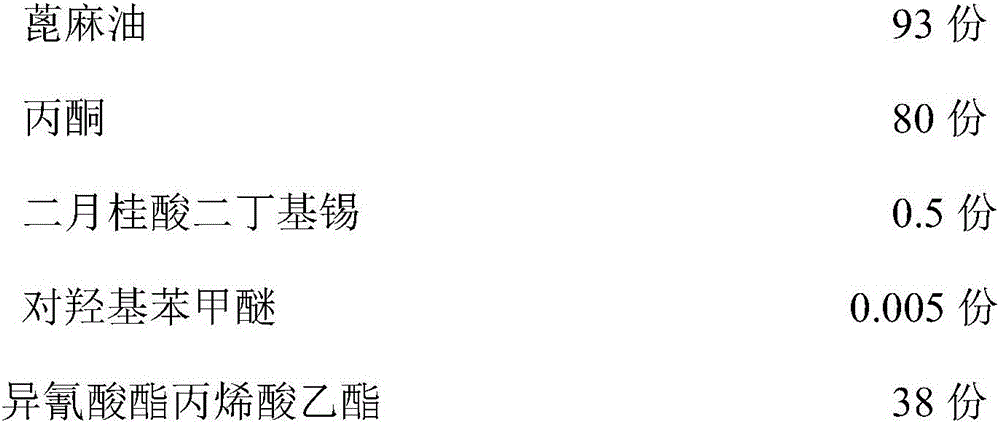

[0029] A. Castor oil modified monomer formula:

[0030]

[0031] After vacuum dehydration of castor oil, add castor oil, acetone, and organotin catalyst into a four-necked flask according to the formula, raise the temperature to 75°C, add isocyanate ethyl acrylate dissolved in p-hydroxyanisole dropwise, and add dropwise for 1.5 hours After the completion of the heat preservation at 75° C. for 1 hour, the NCO content was tested. After the NCO value was <1, the acetone was vacuum removed to obtain 132 parts of castor oil modified monomers.

[0032] B. Castor oil modified emulsion formula:

[0033] (1) Compound emulsifier formula:

[0034] 1 part nonionic emulsifier

[0035] Reactive emulsifier 3 parts

[0036] Prepare compound emulsifiers according to formula.

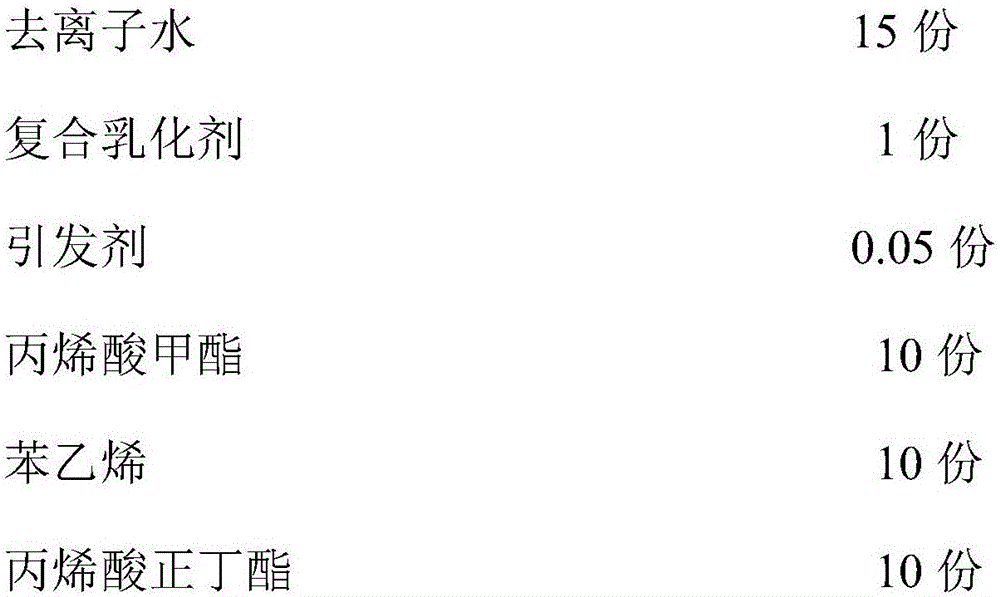

[0037] (2) Nuclear monomer pre-emulsion formula:

[0038]

[0039] Put vinyl monomers or vinyl aromatic compounds that do not contain carboxyl or hydroxyl groups, deionized water, composite emulsifiers and ini...

Embodiment 2

[0046] A. Castor oil modified monomer formula:

[0047]

[0048] After vacuum dehydration of castor oil, add castor oil, acetone, and organotin catalyst into a four-necked flask according to the formula, raise the temperature to 75°C, add isocyanate ethyl acrylate dissolved in p-hydroxyanisole dropwise, and add dropwise for 1.5 hours After the completion of the heat preservation at 75° C. for 1 hour, the NCO content was tested. After the NCO value was less than 1, the acetone was vacuum removed to obtain 120 parts of castor oil modified monomers.

[0049] B. Castor oil modified emulsion formula:

[0050] (1) Compound emulsifier formula:

[0051] 1 part nonionic emulsifier

[0052] Reactive emulsifier 3 parts

[0053] Prepare compound emulsifiers according to formula.

[0054] (2) Nuclear monomer pre-emulsion formula:

[0055]

[0056] Put vinyl monomers or vinyl aromatic compounds that do not contain carboxyl or hydroxyl groups, deionized water, composite emulsifier...

Embodiment 3

[0062] A. Castor oil modified monomer formula:

[0063]

[0064] After vacuum dehydration of castor oil, add castor oil, acetone, and organotin catalyst into a four-necked flask according to the formula, raise the temperature to 75°C, add isocyanate ethyl acrylate dissolved in p-hydroxyanisole dropwise, and add dropwise for 1.5 hours After the completion of the heat preservation at 75° C. for 1 hour, the NCO content was tested. After the NCO value was <1, the acetone was vacuum removed to obtain 132 parts of castor oil modified monomers.

[0065] B. Castor oil modified emulsion formula:

[0066] (1) Compound emulsifier formula:

[0067] 1 part nonionic emulsifier

[0068] Reactive emulsifier 3 parts

[0069] Prepare compound emulsifiers according to formula.

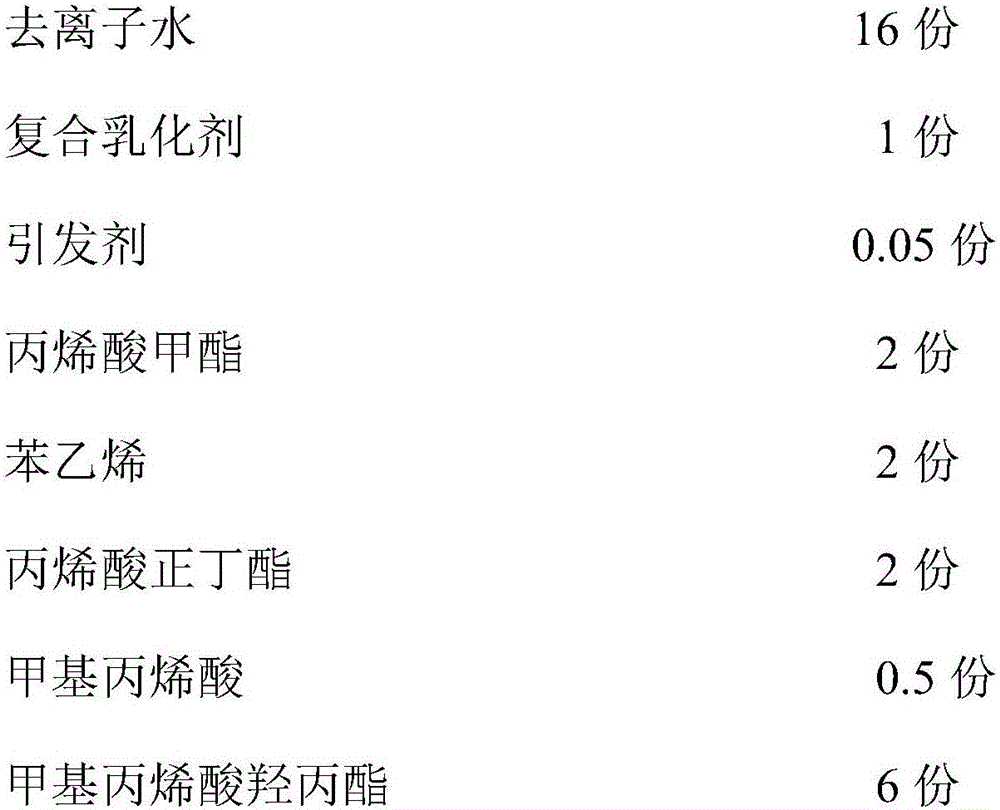

[0070] (2) Nuclear monomer pre-emulsion formula:

[0071]

[0072] Put vinyl monomers or vinyl aromatic compounds that do not contain carboxyl or hydroxyl groups, deionized water, composite emulsifiers and ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com