Ultra-weatherproof carboxyl-terminated fluorine-containing polyester resin for powder coating and preparation method of ultra-weatherproof carboxyl-terminated fluorine-containing polyester resin

A technology of powder coating and fluorine-containing polyester, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of inability to achieve industrialization, poor impact performance, low gloss, etc., and achieve simple resin synthesis process and excellent performance. , high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

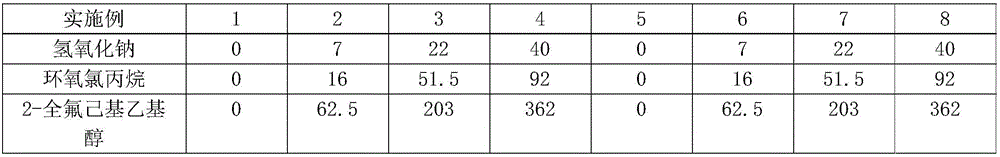

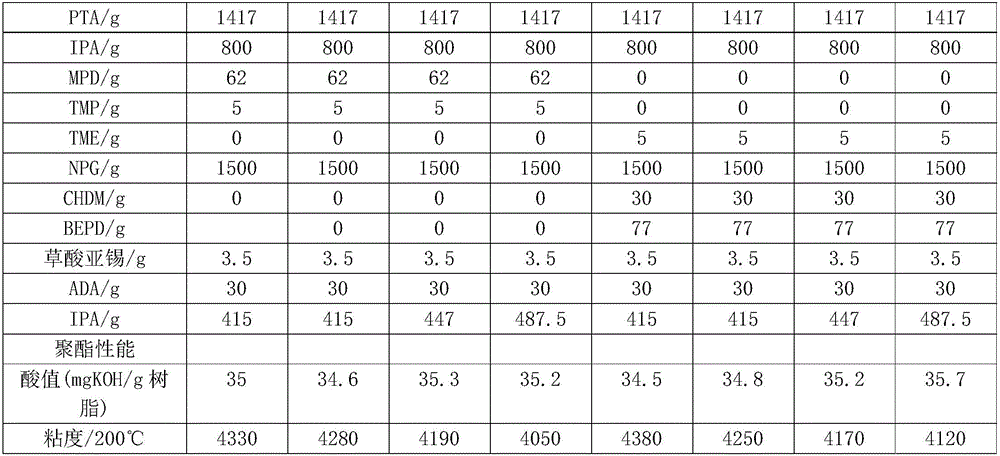

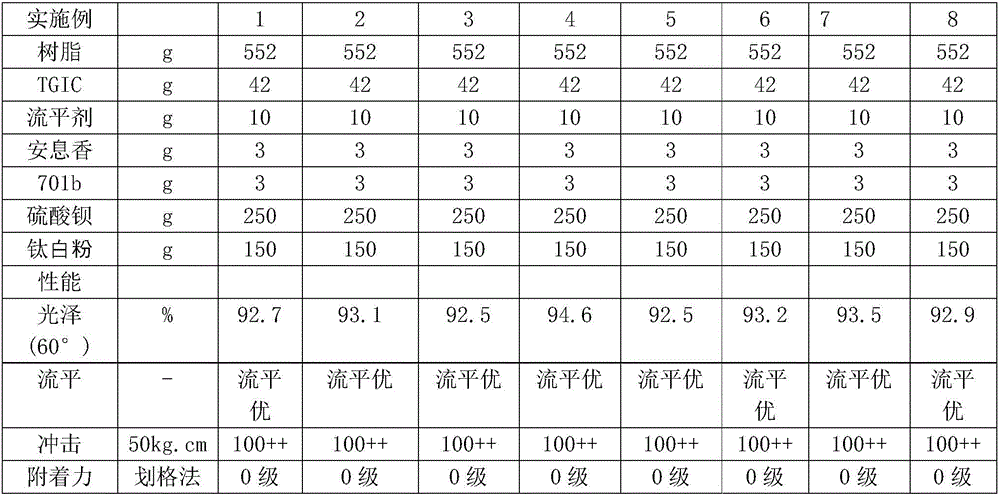

[0036] A super-weather-resistant carboxyl-terminated fluorine-containing polyester resin for powder coatings, the formula is shown in Table 1:

[0037] A method for preparing a super weather-resistant powder coating with a carboxyl-terminated fluorine-containing polyester resin, comprising the following steps:

[0038] 1) Put the proportioning amount of sodium hydroxide and epichlorohydrin into the reaction kettle, then raise the temperature of the system to 70°C, and then add the 2-perfluorohexyl ethyl alcohol in the amount of formula in Table 1 at a rate of 40ml / h Base alcohol is added dropwise in the reactor, maintains 5h, adopts the mode of vacuum distillation to prepare fluorine-containing epoxy compound (F-C-EP) subsequently as the standby of following experiment;

[0039] 2) Add polyhydric alcohol and branching agent in the ratio listed in Table 1 and heat up to melt at 100-140°C, then add the aromatic dibasic acid in the formula in Table 1 in turn, then add the esterif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com