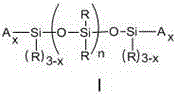

Amino-containing polysiloxane-acrylic ester and preparation method and application thereof

An amine group-containing polysiloxane acrylate and methacrylate technology, which can be used in applications, household appliances, coatings, etc., can solve problems such as limited application and small molecular weight, and achieve the effects of simple operation and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Preparation with octamethylcyclotetrasiloxane as monomer and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane as end-capping agent End-blocked aminopolysiloxane

[0043] Under nitrogen atmosphere, add octamethylcyclotetrasiloxane and end-capping agent 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane to the reaction vessel , Catalyst tetramethylammonium hydroxide and dimethyl sulfoxide (DMSO), the dosage is n (octamethylcyclotetrasiloxane): n (capping agent): n (tetramethylammonium hydroxide) = 1.2 :1.0:1.5, the amount of DMSO is 0.5% of the total mass of octamethylcyclotetrasiloxane and end-capping agent, keep warm at 90°C for 3h, after the reaction, raise the temperature to 140°C, react for 1h; then distill under reduced pressure to remove Low-molecular-weight substances and unreacted raw materials yielded a colorless and transparent blocked aminopolysiloxane.

example example 2

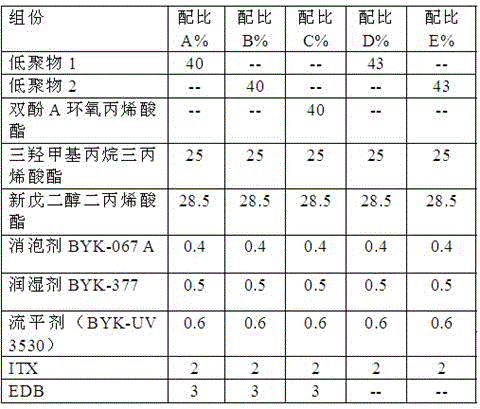

[0044] Example 2: Preparation of amino-containing polysiloxane acrylate oligomer 1

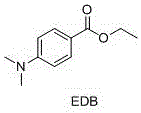

[0045] Add the amino-terminated siloxane and 2-phenoxyethyl acrylate prepared in Example 1 to the reaction vessel, the amount of which is n (amino-terminated siloxane): n (2-phenoxyethyl acrylate) =1:2; heat, keep warm at 40°C and stir for 30 minutes, then raise the temperature to 70°C, keep warm until the double bond is detected by infrared (1645cm -1 ) disappears to stop the reaction, lower the temperature to 40°C; add 1,6-hexanediol diacrylate to the reaction system in an amount of n (aminosiloxane): n(1,6-hexanediol diacrylate ester) = 1:2, and add 0.2% p-hydroxyanisole of the amount of amino-terminated siloxane substances, keep stirring at 40°C for 30min, then raise the temperature to 70°C, keep warm until the infrared detection -NH (3300cm -1 ) disappeared, the reaction was stopped, and the temperature was lowered to room temperature to obtain the corresponding amino-containing polysilo...

Embodiment 3

[0046] Example 3: Preparation of amino-containing polysiloxane acrylate oligomer 2

[0047] Add the amino-terminated siloxane, 2-phenoxyethyl acrylate and tetrahydrofurfuryl acrylate prepared in Example 1 into the reaction vessel in an amount of n(amino-terminated siloxane):n(2-benzene Oxyethyl acrylate): n (tetrahydrofurfuryl acrylate) = 1:1:1; heat, keep warm at 40°C and stir for 30 minutes, then heat up to 70°C, keep warm until the double bond is detected by infrared (1645cm -1 ) disappears to stop the reaction, lower the temperature to 40°C; add 1,6-hexanediol diacrylate to the reaction system in an amount of n (aminosiloxane): n(1,6-hexanediol diacrylate ester) = 1:2, and add 0.2% p-hydroxyanisole of the amount of amino-terminated siloxane substances, keep stirring at 40°C for 30min, then raise the temperature to 70°C, keep warm until the infrared detection -NH (3300cm -1 ) disappears, the reaction is stopped, and the temperature is lowered to room temperature to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com