Polyethylene weathering-resistant color master batch material

A polyethylene and weather-resistant technology, applied in the field of polyethylene material production, can solve the problems of poor heat aging resistance and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0007] (1) The ratio of raw materials according to mass percentage is: polyethylene raw material: 65, titanium dioxide: 2.5, calcium carbonate: 175, talc powder: 170, mica powder: 170, kaolin: 170, silicon dioxide: 170, dispersing lubricant (TAS-2A): 1.0, UV absorber (2-hydroxy-4-n-octyloxybenzophenone): 9.0, light stabilizer: 9.0, antioxidant (ethylene-octene copolymer): 12.0. Colorant: 5.0.

[0008] (2) The preparation method is as follows: first dry mix various raw materials in a high-speed mixer for 3-5 minutes, then place them in a twin-screw extruder, melt and extrude, cool, pelletize, and pack the finished product; wherein, The temperature of twin-screw extruder zone 1 is 90-100°C, zone 2 is 160-190°C, zone 3 is 200-210°C, zone 4 is 205-210°C; zone 5 is 190-200°C, and the residence time is 1 -2 minutes, the pressure is 10-15Mpa.

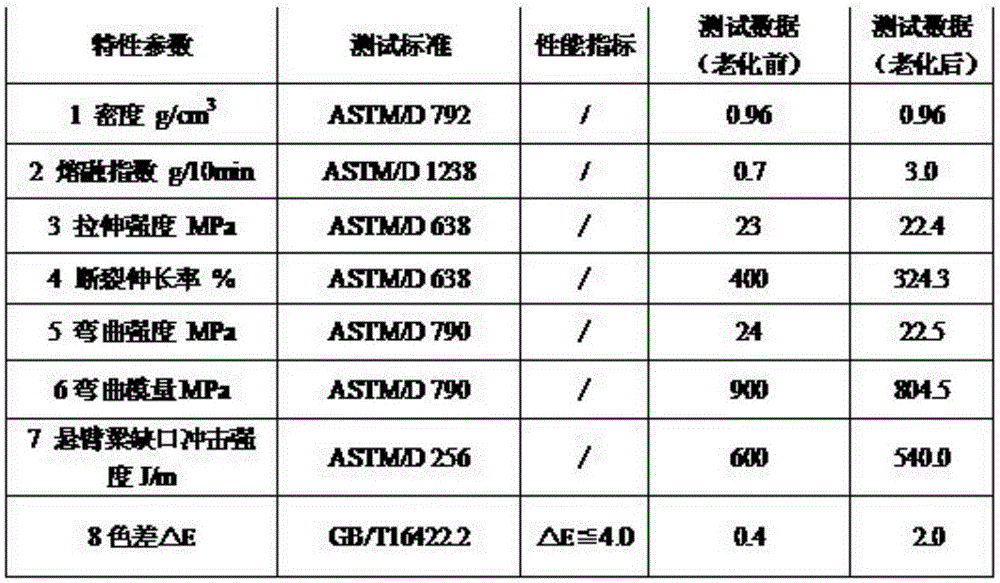

[0009] Experimental results

[0010]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com