Coating material, protective coating and construction method of protective coating

A coating material and protective layer technology, applied in the field of anti-corrosion and heat preservation, can solve the problems of long time-consuming and difficult construction process, and achieve the effects of improving anti-corrosion ability, enhancing adhesion, and enhancing heat preservation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

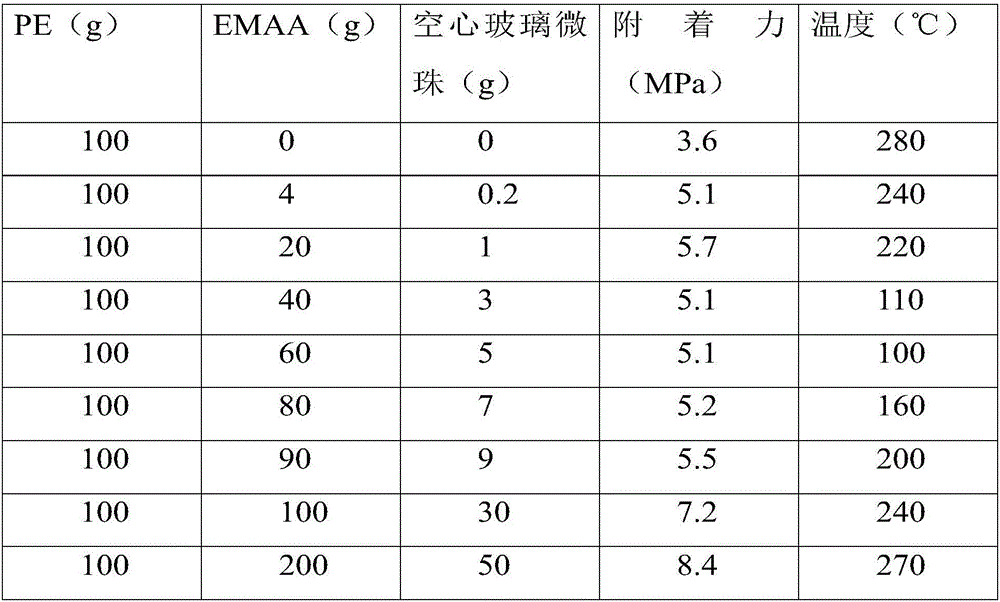

[0040] This embodiment provides a coating material, including the following raw materials: low-density linear PE (powder), EMAA (powder), and hollow glass microspheres. The specific amounts of raw materials are shown in Table 1.

[0041] This embodiment also provides a protective layer, which is prepared by spraying and foaming the above-mentioned coating material.

[0042] The specific construction method of the above protective layer is as follows: add EMAA to PE according to different proportions, stir and mix and ball mill for 24 hours to obtain a mixed powder, then add hollow glass microspheres to the mixed powder, and ball mill for 12 hours to obtain a mixed material. Put the mixture into the pre-prepared flame spraying gun, pressurize the interior of the flame spraying gun containing the mixture to 200kPa, and control the flame temperature at the outlet of the flame spraying gun at 110-200. Prepare 9 ordinary steel plates of the same material, and the steel plates have ...

Embodiment 2

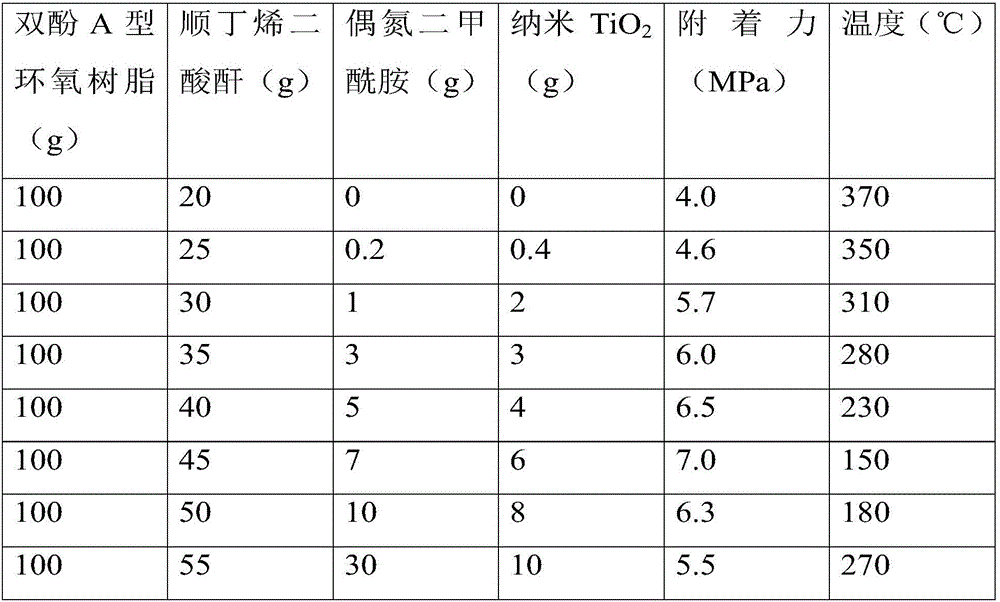

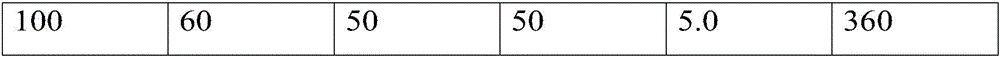

[0051] This embodiment provides a coating material, including the following raw materials: azodicarbonamide, diphenol propane type epoxy resin (abbreviated as bisphenol A type epoxy resin), maleic anhydride, nano TiO 2 , see Table 2 for the specific dosage of each component.

[0052] This embodiment also provides a protective layer constructed from the above coating materials.

[0053] The specific construction method is as follows: azodicarbonamide, bisphenol A epoxy resin, nano-TiO 2 Mechanically mixed and ball milled for 48 hours to obtain a mixed powder. Then add maleic anhydride to the mixed powder, stir and mix to obtain a mixed material. Put the mixture into the pre-prepared flame spraying gun, and control the flame temperature at the outlet of the flame spraying gun at 210-250°C. Prepare 9 ordinary steel plates of the same material, and the steel plates have been subjected to the same sandblasting treatment in advance. Use a flame spray gun to spray a coating mater...

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 2 is that the coating material is prepared from the following raw materials: polyvinyl chloride 100g (thermoplastic), thermally expandable microspheres 6g, 4,4'-oxobisbenzenesulfonylhydrazide 4g, nanometer A1 2 o 3 3g, Nano SiO 2-x 2g. The difference between the construction method of coating material and embodiment 2 is: earlier polyvinyl chloride, nanometer A1 2 o 3 , nano-SiO 2-x Melting and blending at 230°C, the prepared mixture was crushed and ball-milled for 48 hours, then added with heat-expandable microspheres and 4,4'-oxobisbenzenesulfonyl hydrazide, and ball-milled for 12 hours to obtain a mixture. The mixture is heated to make it in a flowing state, and the mixture is quickly coated on the plate made of acrylonitrile-butadiene-styrene copolymer (ABS) by manual coating. Heat the other side of the ABS plate and stop when the heating reaches 100°C. After 5 minutes, measure the temperature of the outer surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com