Multifunctional paint and preparation method thereof

A multi-functional, coating technology that can be used in the coating field to solve problems such as poor environmental protection, low consumer acceptance, and poor stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

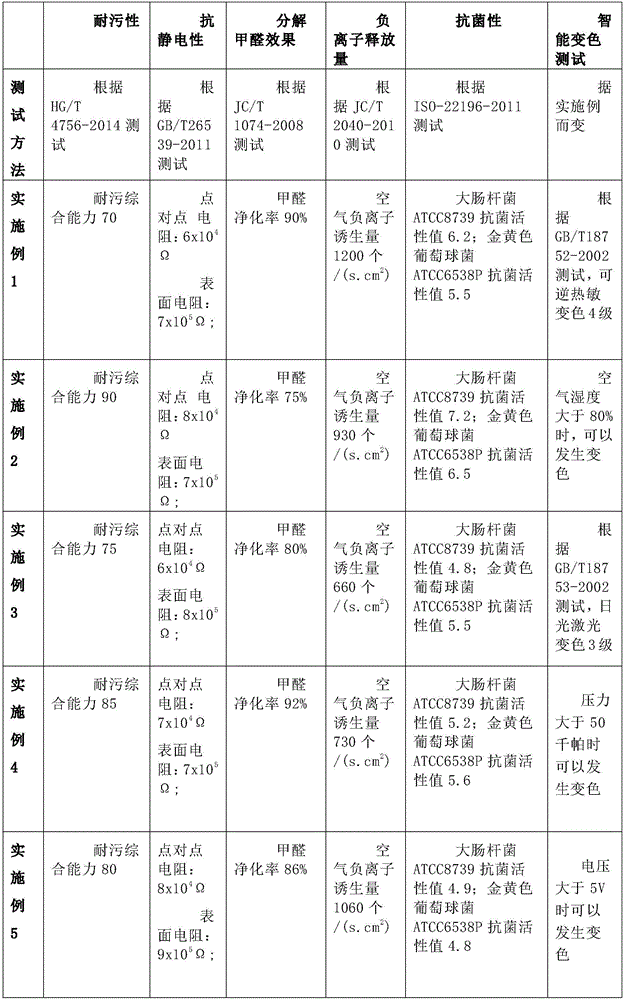

Examples

Embodiment 1

[0022] This embodiment relates to a kind of multi-functional coating, and this multi-functional coating comprises the following components in mass percent: composite filler 15%, discoloration factor 8%, antifreeze 0.5%, emulsion 35%, wetting agent 0.3%, 0.6% defoamer, 0.8% thickener, 0.5% neutralizer, 0.2% antifungal agent, 0.4% dispersant, 0.6% film-forming aid, 3% reducing solution, 35.1% water; among them, composite filler In parts by weight, it contains 5 parts of neodymium silicate crystals, 1 part of tourmaline powder, 15 parts of calcined diatomite, and 1 part of rare earth containing indium; the thickener includes cellulose thickener and polyurethane thickener, cellulose thickener The weight ratio with polyurethane thickener is: 1:2.

[0023] Specifically, the regenerating solution is an extract containing Polygonum cuspidatum and Sansevieria Phnom Penh. The extract is a natural component that can absorb positive ions in the air, reduce the adsorption of positive ions ...

Embodiment 2

[0035] This embodiment relates to a kind of multi-functional coating, and this multi-functional coating comprises the following components in mass percent: 15% of composite fillers, 4% of wet-feeling material particles, 1% of antifreeze, 65% of emulsion, and 0.3% of wetting agent %, defoamer 1.1%, thickener 1%, neutralizer 0.9%, antifungal agent 0.2%, dispersant 0.4%, film-forming aid 1.1%, reducing solution 3%, water 7%;

[0036] Wherein, the composite filler comprises 5 parts by weight of neodymium silicate crystal, 1 part of tourmaline powder, 15 parts of calcined diatomite, and 1 part of rare earth containing indium;

[0037] The thickener includes a cellulose thickener and a polyurethane thickener, and the weight ratio of the cellulose thickener to the polyurethane thickener is 1:3.

[0038] In addition, each component involved in this example can be obtained through market purchase, wherein, the model and manufacturer of each component are as follows: the wet-sensing mat...

Embodiment 3

[0047] This embodiment relates to a multifunctional coating, which comprises the following components in mass percentage: 30% of composite filler, 10% of photosensitive material particles, 0.7% of antifreeze, 40% of emulsion, and 0.4% of wetting agent , defoamer 0.7%, thickener 0.4%, neutralizer 0.6%, antifungal agent 0.5%, dispersant 0.6%, film-forming aid 0.5%, reducing solution 4%, water 11.6%;

[0048] Wherein, the composite filler includes 10 parts by weight of neodymium silicate crystal, 6 parts of tourmaline powder, 18 parts of calcined diatomite, and 3 parts of rare earth containing indium;

[0049] The thickener includes a cellulose thickener and a polyurethane thickener, and the weight ratio of the cellulose thickener to the polyurethane thickener is 1:4.

[0050] In addition, each component involved in this example can be purchased from the market, and the model and manufacturer of each component are as follows: the photosensitive material particle is photosensitive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com