Preparation method of large-particle-size low-viscosity silica solution for polishing sapphire

A technology with large particle size and low viscosity, which is applied in chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes. It can solve problems such as high surface roughness, affecting product quality, and low production efficiency. High polishing efficiency, easy control of particle size, avoiding the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

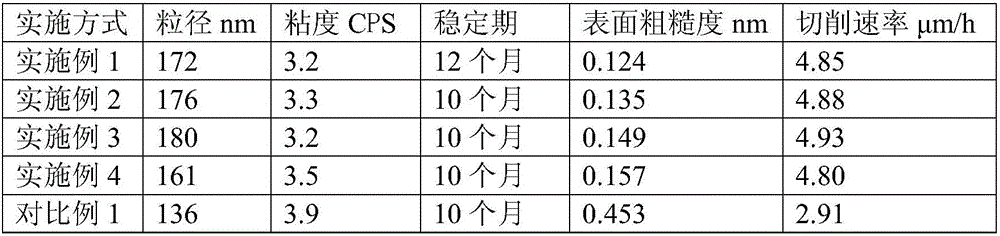

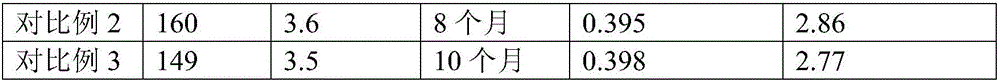

Examples

Embodiment 1

[0022] A preparation method for sapphire polishing with large particle size and low viscosity silica sol, comprising the following steps:

[0023] (1) Take a certain amount of sodium hydroxide and join in water to make a 3wt% sodium hydroxide solution;

[0024] (2) adding 10 parts by weight of silicon powder to 24 parts by weight of water, and activating at 65°C for 30 minutes to obtain activated silicon powder;

[0025] (3) Add 0.8 parts by weight of dibenzofuran to 15 parts by weight of ethanol, stir and mix evenly, and heat to 45°C for 40 minutes to obtain a dibenzofuran solution;

[0026] (4) In 20 parts by weight of water, add 4 parts by weight of glycerol, stir and mix evenly, and heat to 70°C, then slowly add the activated silicon powder and the dibenzofuran solution, supplemented with 50KHz ultrasonic treatment, and dropwise adding the sodium hydroxide solution, the dropping speed and the dropping amount of the sodium hydroxide solution are based on maintaining the pH...

Embodiment 2

[0029] A preparation method for sapphire polishing with large particle size and low viscosity silica sol, comprising the following steps:

[0030] (1) Take a certain amount of sodium hydroxide and join in water to make a 3wt% sodium hydroxide solution;

[0031] (2) adding 10 parts by weight of silicon powder to 24 parts by weight of water, and activating at 65°C for 30 minutes to obtain activated silicon powder;

[0032] (3) Add 0.8 parts by weight of dibenzofuran to 15 parts by weight of ethanol, stir and mix evenly, and heat to 45°C for 40 minutes to obtain a dibenzofuran solution;

[0033] (4) In 20 parts by weight of water, add 4 parts by weight of glycerol, stir and mix evenly, and heat to 70°C, then slowly add the activated silicon powder and the dibenzofuran solution, and add dropwise The sodium hydroxide solution, the rate of addition and the amount of addition of the sodium hydroxide solution are based on maintaining the pH of the reaction system to be 9 to 10;

[0...

Embodiment 3

[0036] A preparation method for sapphire polishing with large particle size and low viscosity silica sol, comprising the following steps:

[0037] (1) Take a certain amount of sodium hydroxide and join in water to make 4wt% sodium hydroxide solution;

[0038] (2) adding 10 parts by weight of silicon powder to 21 parts by weight of water, and activating at 68°C for 20 minutes to obtain activated silicon powder;

[0039] (3) Add 1 part by weight of dibenzofuran into 15 parts by weight of ethanol, stir and mix evenly, and heat to 40°C for 30 minutes to obtain a dibenzofuran solution;

[0040] (4) In 20 parts by weight of water, add 5 parts by weight of glycerol, stir and mix evenly, and heat to 60°C, then slowly add the activated silicon powder and the dibenzofuran solution, and dropwise The sodium hydroxide solution, the rate of addition and the amount of addition of the sodium hydroxide solution are based on maintaining the pH of the reaction system to be 9 to 10;

[0041] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com