A solid heat carrier coal gasification power storage system and method

A solid heat carrier, coal gasification technology, applied in the gasification process, granular/powder fuel gasification, production of combustible gas, etc., can solve the problems of environmental pollution, high investment cost and poor economy of electrolytic aluminum technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

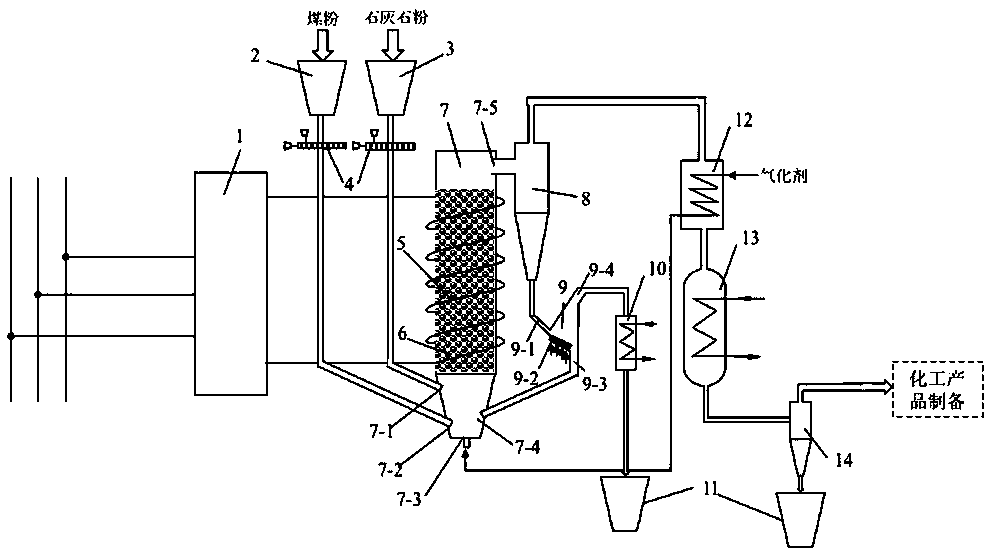

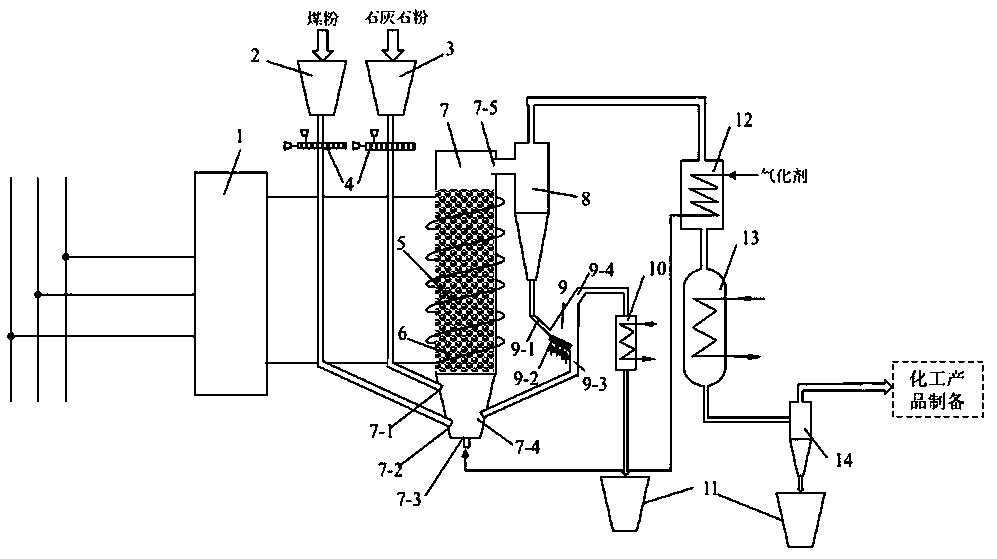

[0102] A solid heat carrier coal gasification electric energy storage method is to adopt such as figure 1 In the electric energy storage system shown, the main body of the fluidized bed pulverized coal gasifier used in the system is cylindrical, with a cross-sectional area of 4m 2 , the height is 9m; the electric heating element is an electromagnetic induction coil; the metal heat carrier is a small steel ball with a diameter of 1.2mm, which is filled in a fluidized bed pulverized coal gasifier, and the filling height is 6m. The energy storage method includes the following steps:

[0103] (1) Determine the peak-shaving amount of the power grid according to the actual power consumption in the off-peak period, and set the power load;

[0104] (2) Introduce electrical energy into the fluidized bed pulverized coal gasification furnace to heat the metal heat carrier until the temperature reaches 1000°C and remains constant;

[0105] (3) Put the pulverized coal and limestone into...

Embodiment 2

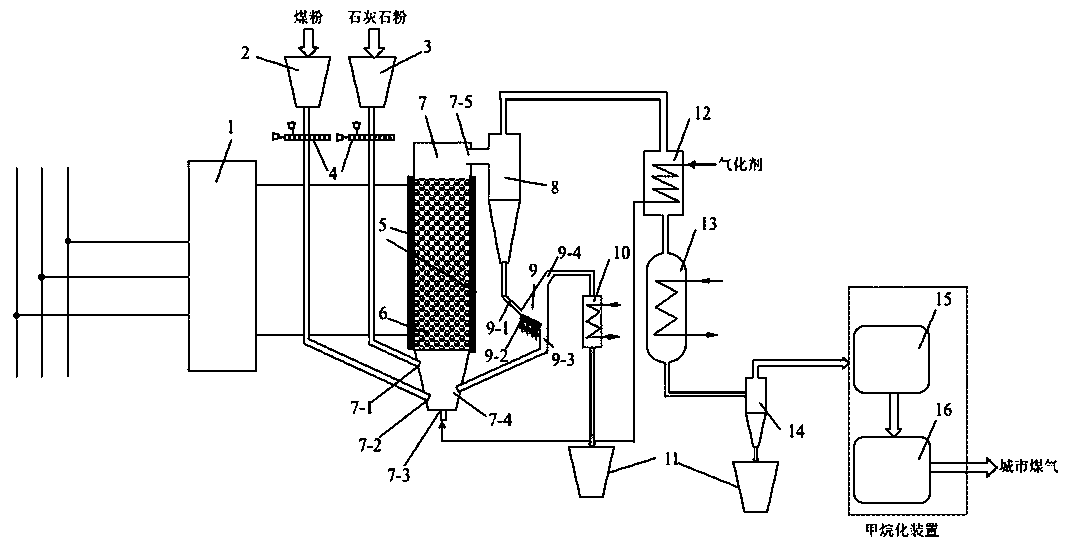

[0110] A solid heat carrier coal gasification electric energy storage method is to adopt such as figure 2 In the electric energy storage system shown, the main body of the fluidized bed pulverized coal gasifier used in the system is cylindrical, with a cross-sectional area of 4m 2 , the height is 9m; the electric heating element is a resistive heating body; the metal heat carrier is a small steel ball with a diameter of 1.2mm, which is filled in a fluidized bed pulverized coal gasifier, and the filling height is 6m. The energy storage method includes the following steps :

[0111] (1) Determine the peak-shaving amount of the power grid according to the actual power consumption in the off-peak period, and set the power load;

[0112] (2) Introduce electrical energy into the fluidized bed pulverized coal gasification furnace to heat the metal heat carrier until the temperature reaches 1000°C and remains constant;

[0113] (3) Put coal powder and limestone into the fluidized...

Embodiment 3

[0118] A solid heat carrier coal gasification electric energy storage method is to adopt such as figure 1 In the multiple sets of electric energy storage systems shown, the main body of the fluidized bed pulverized coal gasifier used in the multiple sets of systems is cylindrical, with a cross-sectional area of 4m 2 , the height is 9m; the electric heating element is an electromagnetic induction coil; the metal heat carrier is a small steel ball with a diameter of 1.2mm, which is filled in a fluidized bed pulverized coal gasifier, and the filling height is 6m. The energy storage method includes the following steps:

[0119] (1) Determine the peaking amount of the power grid according to the actual power consumption in the off-peak period, set the power load, and connect multiple sets of power grid peaking systems in parallel;

[0120] (2) Introduce electrical energy into the fluidized bed pulverized coal gasification furnace to heat the metal heat carrier until the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com