Glass cleaning agent and use method thereof

A glass cleaning agent and glass technology, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of glass surface being bluish, damaging the glass surface, surface roughening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Provide a kind of glass cleaning agent formula, the composition of described glass cleaning agent formula is: 3.5 parts of potassium hydroxide, 5 parts of sodium hydroxide, 1 part of potassium carbonate, 0.8 part of sodium lauryl sulfate, no 1.3 parts of sodium metasilicate in water, 4 parts of diethylene glycol butyl ether, 2.5 parts of nonylphenol polyoxyethylene ether, 0.2 parts of octenyl succinic anhydride, and the remaining amount of water, add the components of the glass cleaner formula Stir it into the pottery, and get the glass cleaning agent after mixing evenly.

Embodiment 2

[0040] Provide a kind of glass cleaner formula, the composition of described glass cleaner formula is: based on 100 parts by mass, 4 parts of potassium hydroxide, 4.5 parts of sodium hydroxide, 1.8 parts of potassium carbonate, 0.8 parts of sodium lauryl sulfate, 1.5 parts of anhydrous sodium metasilicate, 4 parts of diethylene glycol butyl ether, 4.5 parts of nonylphenol polyoxyethylene ether, 0.4 part of octenyl succinic anhydride, and the remaining amount of water, the components of the glass cleaner formula Add it into the aluminum container and stir, and get the glass cleaning agent after mixing evenly.

Embodiment 3

[0042] A glass cleaning agent formula is provided, the glass cleaning agent formula is composed of: in parts by mass, 5 parts of potassium hydroxide, 4 parts of sodium hydroxide, 2 parts of potassium carbonate, 1 part of sodium lauryl sulfate, no 1 part of sodium metasilicate in water, 5 parts of ethylene glycol butyl ether, 4.5 parts of nonylphenol polyoxyethylene ether, 0.5 part of octenyl succinic anhydride, and the remaining amount of water, add the components of the glass cleaner formula Stir it into the pottery, and get the glass cleaning agent after mixing evenly.

[0043] product instructions:

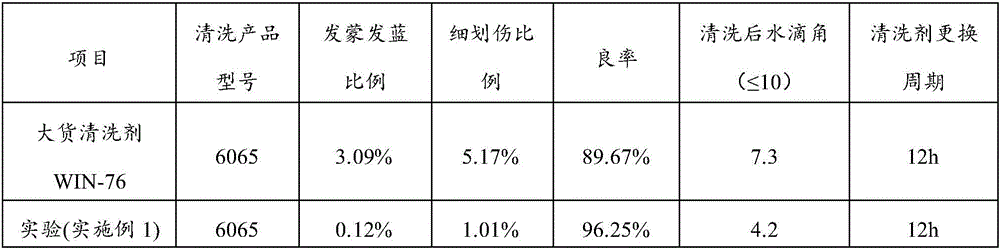

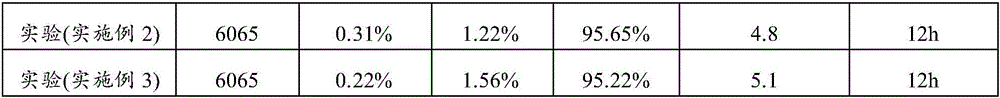

[0044] Clean the optical glass product with the glass cleaning agent prepared in Examples 1-3, after diluting the cleaning agent 20 times, the pH value is 12.5-13.5, use the touch screen glass of the mobile phone as the cleaning test piece, and put it into the solvent tank of the ultrasonic cleaning machine for cleaning , the temperature is set to 65°C, and the time is set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com