Method for lowering internal stress of corrugated pipe

A bellows and internal stress technology, applied in the field of refrigeration, can solve the problems of poor stability of bellows, stable flow changes, stable flow fluctuations of refrigerators, etc., and achieve the effects of improving poor stability, low process difficulty, and reduced internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

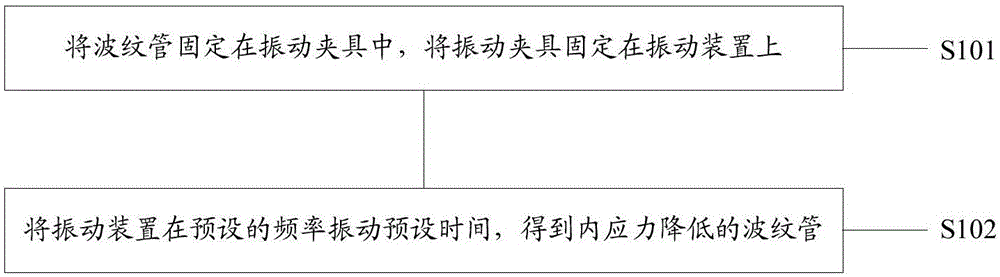

[0038] A method for vibration aging treatment to reduce the internal stress of the bellows of a self-regulating refrigerator includes the following steps:

[0039] (1) Put the polytetrafluoroethylene sleeve in any straight hole of the stainless steel vibrating fixture, put the experimental bellows into the straight hole, and fix it with screws through the flange.

[0040] (2) Put the vibrating jig with bellows on the vibrating table of the vibrating device and fix it stably. The vibration frequency is set to 500Hz, vibrate for 1 hour, and the corrugated pipe taken out after the vibration is finished is the corrugated pipe whose internal stress has been reduced after aging through vibration treatment.

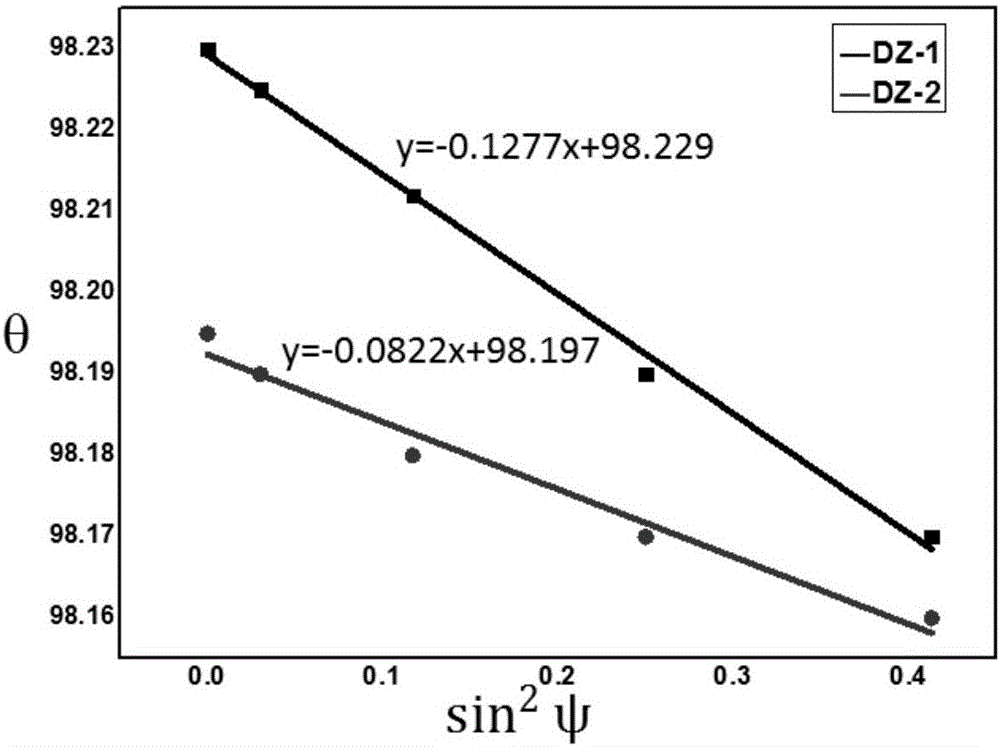

[0041] According to the material analysis method, the stress calculation formula σ=K·M, where K is the stress constant, M is the diffraction angle θ to the diffraction crystal plane azimuth angle sin 2 The change slope of ψ was measured by X-ray diffractometer to measure the an...

example 2

[0043] A method for vibration aging treatment to reduce the internal stress of the bellows of a self-regulating refrigerator includes the following steps:

[0044] (1) Put the polytetrafluoroethylene sleeve in any straight hole of the stainless steel vibrating fixture, put the experimental bellows into the hole, and fix it with screws through the flange.

[0045](2) Put the vibrating jig with bellows on the vibrating table of the vibrating device and fix it stably. The vibration frequency is set to 2.5KHz, vibrate for 1 hour, and the corrugated pipe taken out after the vibration is completed is the corrugated pipe whose internal stress has been reduced after aging through vibration treatment.

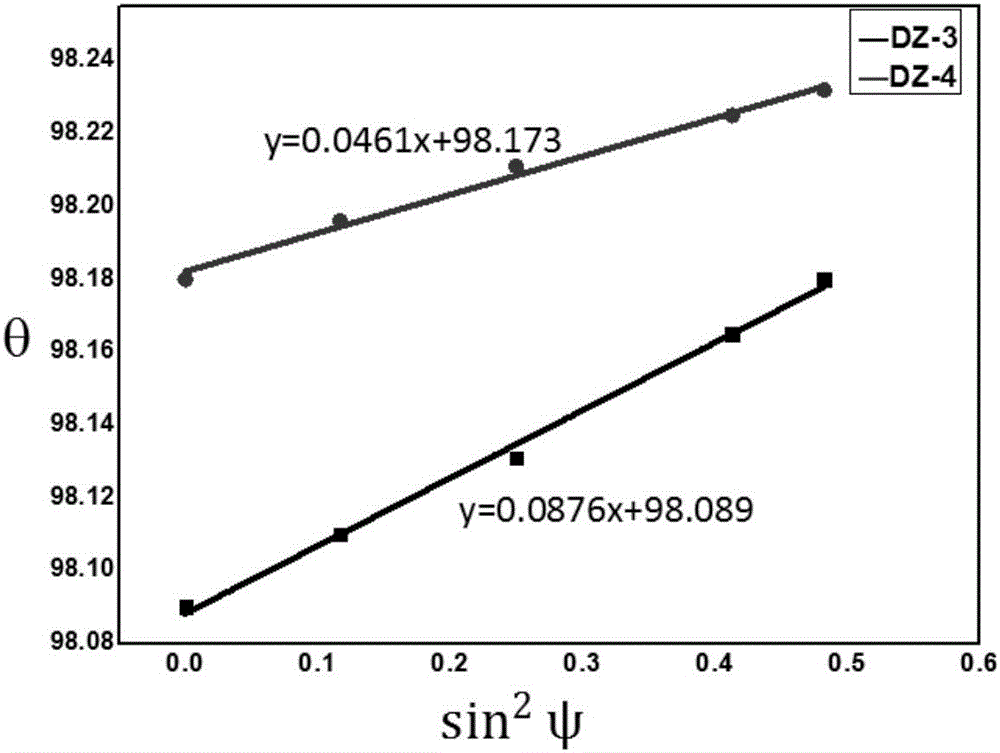

[0046] According to the material analysis method, the stress calculation formula σ=K M, where K is the stress constant, M is the diffraction angle θ to the diffraction crystal plane azimuth angle sin 2 The change slope of ψ is measured by X-ray diffractometer to measure the angle relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com