A method for separating lead, antimony and arsenic from anode slime alkaline leaching solution

An anode slime and lead separation technology, applied in the field of separation of lead, antimony and arsenic, can solve the problems of high separation coefficient, invisible, incomplete separation of arsenic and antimony, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

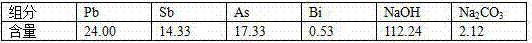

Embodiment 1

[0032] Embodiment 1: A method for separating lead, antimony and arsenic from anode slime alkaline leaching solution, the specific steps include:

[0033] (1) Add 500g of antimony-lead alloy powder with a particle size of less than 300 mesh and 120g of sodium nitrate (the mass ratio of antimony-lead alloy powder to sodium nitrate is 25:6) into a 10L reactor, and add 6.2L of 120g / L NaOH solution (according to the liquid-solid ratio in the reactor: mL:g is 10:1), at a temperature of 200°C and a stirring speed of 350rpm, leaching for 1.5h, after the reaction is completed, cool to 100°C, and filter to obtain lead (II) sodium salt (Na 2 PbO 2 ) and antimony (Ⅲ) sodium salt (NaSbO 2 ) mixed solution; add sodium nitrite into the mixed solution according to the liquid-solid ratio mL:g of 100:1, and react at a temperature of 100°C for 30 minutes to oxidize antimony (Ⅲ) to antimony (Ⅴ); Cool to 30°C and crystallize for 18 hours to obtain lead pyroantimonate (Pb 2 Sb 2 o 7 ) seed; ...

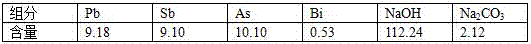

Embodiment 2

[0038] Embodiment 2: A method for separating lead, antimony and arsenic from anode slime alkaline leaching solution, the specific steps include:

[0039] (1) Add 500g of antimony-lead alloy powder with a particle size of less than 300 mesh and 160g of sodium nitrite (the mass ratio of antimony-lead alloy powder to sodium nitrite is 25:8) into a 10L reaction kettle, and add 7.92 L at a concentration of 130g / L of NaOH solution (the ratio of liquid to solid in the reactor is 12:1 in mL:g), leached for 2.5h at a temperature of 230°C and a stirring speed of 250 rpm. After the reaction was completed, it was cooled to 110°C and filtered to obtain lead ( Ⅱ) acid sodium salt (Na 2 PbO 2 ) and antimony (Ⅲ) sodium salt (NaSbO 2 ) mixed solution; add sodium nitrite to the mixed solution according to the liquid-solid ratio mL:g of 70:1, and react at a temperature of 105°C for 40 minutes to oxidize antimony (Ⅲ) to antimony (Ⅴ); cool the reaction solution to 25 ℃, the crystallization tim...

Embodiment 3

[0041] Embodiment 3: A method for separating lead, antimony and arsenic from anode slime alkaline leaching solution, the specific steps include:

[0042] (1) Add 500g of antimony-lead alloy powder with a particle size of less than 300 mesh and 160g of sodium nitrate (the mass ratio of antimony-lead alloy powder to sodium nitrate is 25:8) into a 10L reactor, and add 7.26L of 150g / L NaOH solution (the ratio of liquid to solid in the reactor is 11:1 mL:g), leached for 1.8h at a temperature of 250°C and a stirring speed of 350rpm, after the reaction was completed, cooled to 105°C, filtered to obtain lead (II) acid Sodium salt (Na 2 PbO 2 ) and antimony (Ⅲ) sodium salt (NaSbO 2 ) mixed solution; add sodium nitrite to the mixed solution according to the liquid-solid ratio mL:g of 90:1, and react at a temperature of 108°C for 50 minutes to oxidize antimony (Ⅲ) to antimony (Ⅴ); cool the reaction solution to 35°C, the crystallization time was 17 h, and lead pyroantimonate (Pb 2 Sb ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com