A kind of carbon dot/polyurethane composite material and its preparation method and application

A composite material and polyurethane technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve separation difficulties, small carbon dot size, and unreported inventions, etc. problem, to achieve the effect of simple preparation process, easy separation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

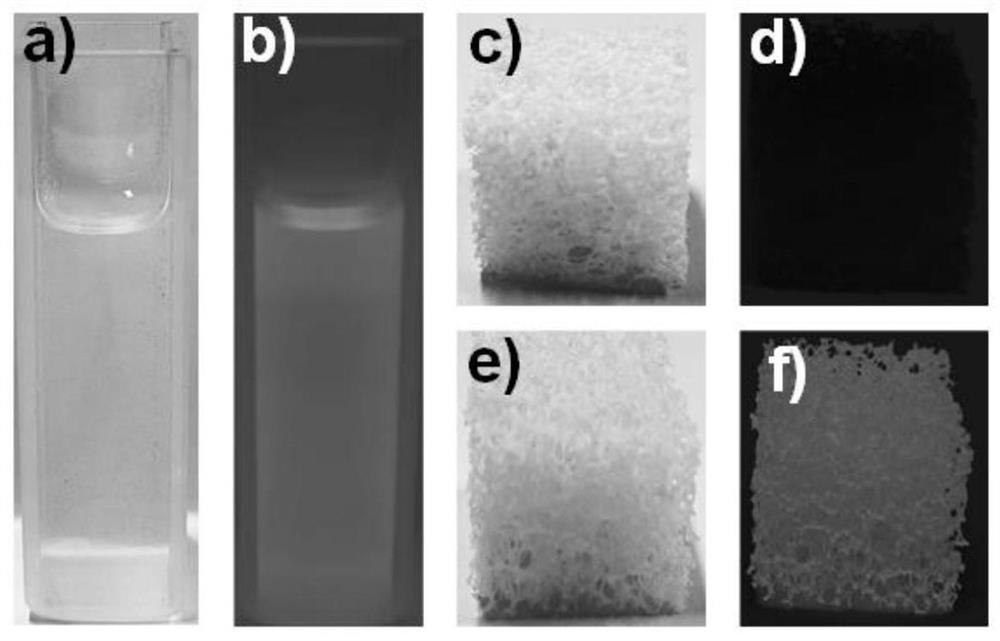

[0034] (1) Synthesize yellow light carbon dots by hydrothermal method: weigh 2.3g of neutral red with a balance and dissolve in 60mL of ethylene glycol, and stir for 30 minutes. Then it was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reactor and reacted at 200°C for 4 hours. After the reaction was finished, it was naturally cooled to room temperature, and the reacted solution and solid were taken out, and centrifuged and washed with a mixed solution of n-hexane and acetone (volume ratio: 95:5). After centrifugation, take the supernatant in a beaker, which is the carbon dot solution used later, and its concentration is 0.1g / L.

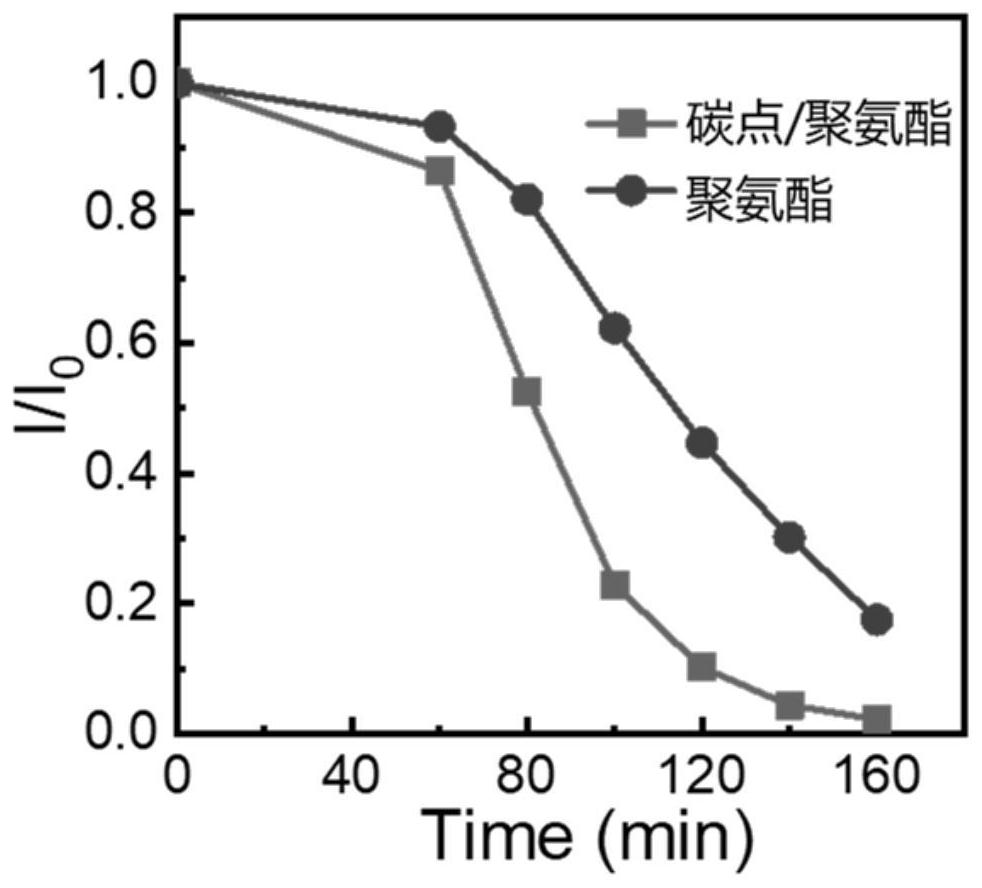

[0035](2) Synthesis of carbon dots / polyurethane composite material: Polyurethane is a commercially available polyurethane foam, which is cut into cubes of 2cm*2cm*2cm (the porosity of the polyurethane foam is 93%). Get 20mL of the carbon dot solution in step (1), immerse the polyurethane foam block (0.2g) in the carbon d...

Embodiment 2

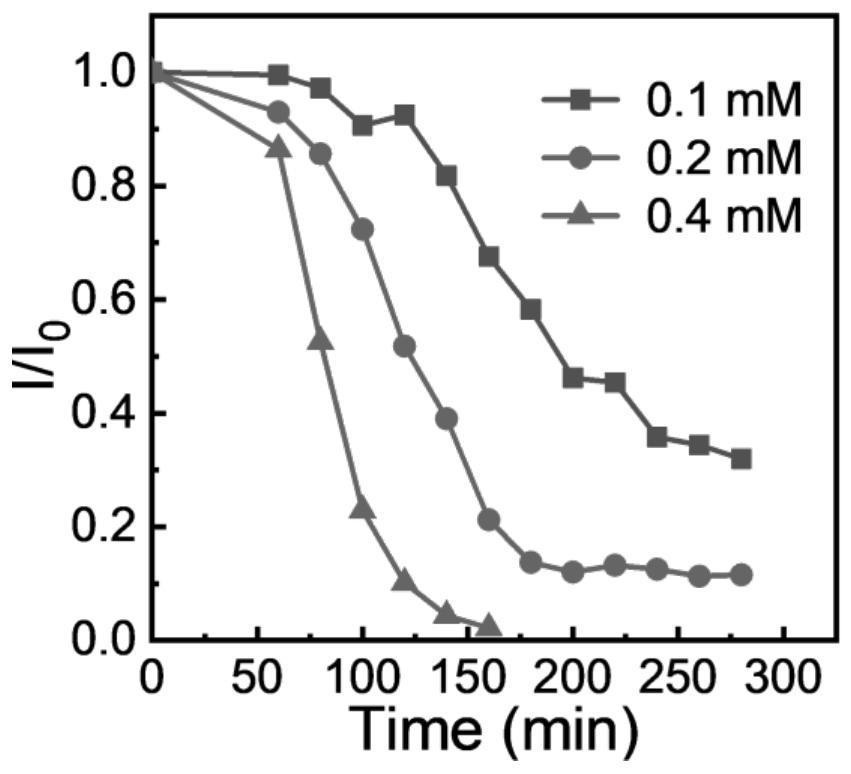

[0044] (1) Synthesize yellow light carbon dots by hydrothermal method: weigh 2.3g of neutral red with a balance and dissolve in 60mL of ethylene glycol, and stir for 30 minutes. Then it was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal reactor and reacted at 200°C for 4 hours. After the reaction was finished, it was naturally cooled to room temperature, and the reacted solution and solid were taken out, and centrifuged and washed with a mixed solution of n-hexane and acetone (volume ratio: 95:5). After centrifugation, take the supernatant in a beaker, and this supernatant is the carbon dot solution used later.

[0045] (2) Synthesis of carbon dots / polyurethane composites:

[0046] Take 10g of polyethylene glycol and 5g of 4,4'-dicyclohexylmethane diisocyanate, stir and mix evenly, and react at a constant temperature of 80°C to obtain product A; add 10PEG-2000, 0.7g of simethicone and 0.7g of liquid paraffin, drop 3 Drop dibutyltin dilaurate, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com