Technological method for recovering germanium from low-concentration germanium-containing waste liquid

A process method and low-concentration technology, applied in the field of germanium recycling, can solve the problems of large processing capacity, high processing cost, and the recovery rate is difficult to exceed 95%, and achieve low recovery efficiency, high recovery cost, and reduced waste liquid volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

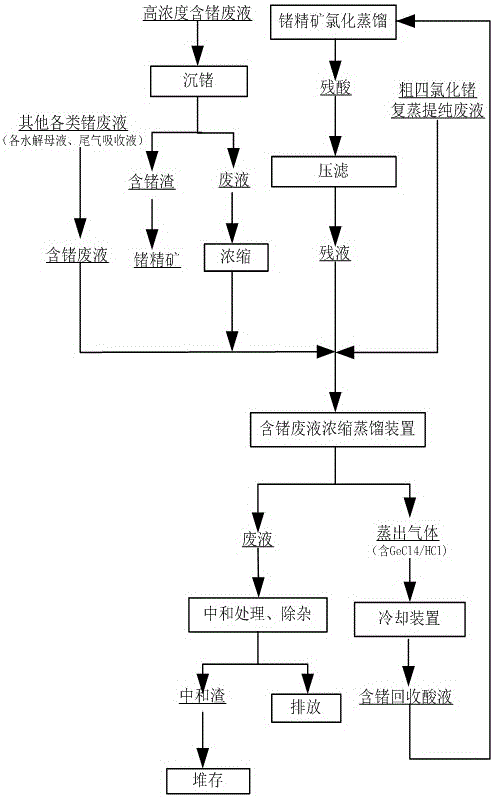

Image

Examples

Embodiment 1

[0013] Example 1: The process for recovering germanium from low-concentration germanium-containing waste liquid is implemented according to the following steps:

[0014] (1) Transfer a total of 30 tons of low-concentration germanium-containing waste liquid produced during the germanium smelting and production process, containing 40.0mg / L germanium, to the distillation kettle in 6 batches;

[0015] (2) Turn on the heating steam to heat and distill the low-concentration germanium-containing waste liquid at a distillation temperature of 115 ℃; at the same time, cool the germanium tetrachloride and hydrogen chloride gas produced by the distillation;

[0016] (3) The gas from the cooling device adopts hydrochloric acid solution to absorb germanium tetrachloride and hydrogen chloride gas in reverse;

[0017] (4) The recovered germanium-containing acid solution is gradually transferred to the germanium concentrate chlorination distillation unit, and used together with new hydrochloric acid to...

Embodiment 2

[0019] Embodiment 2: The process for recovering germanium from low-concentration germanium-containing waste liquid is implemented according to the following steps:

[0020] (1) A total of 60 tons of low-concentration germanium-containing waste liquid produced during the company's germanium smelting and production process, containing 30.0 mg / L germanium, was transferred to the still in 10 batches;

[0021] (2) Turn on the heating steam to heat and distill the low-concentration germanium-containing waste liquid at a distillation temperature of 120 ℃; at the same time, cool the germanium tetrachloride and hydrogen chloride gas produced by the distillation;

[0022] (3) The gas from the cooling device adopts hydrochloric acid solution to reversely absorb germanium tetrachloride and hydrogen chloride gas;

[0023] (4) The recovered germanium-containing acid solution is gradually transferred to the germanium concentrate chlorination distillation unit, and used together with new hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com