Flux for refining aluminum and aluminum alloy melts and method for refining aluminum and aluminum alloy melts

A technology of aluminum alloy melt and flux, which is applied in the field of flux for refining aluminum and aluminum alloy melt and in the field of refining aluminum and aluminum alloy melt, which can solve the problem of unsatisfactory refining effect and deterioration, grain refinement, and influence on casting Ingot or casting performance, complex process and other issues, to avoid further oxidation, improve refining effect, enhance the effect of adsorption and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the flux for aluminum and aluminum alloy melt refining comprises the following steps:

[0022] S1. Crushing the components of the above-mentioned first flux, and passing through a sieve of 80 to 100 meshes for screening;

[0023] S2. Weigh the screened components by mass percentage, mix and stir for 5-10 minutes, and prepare the dry material mixture of the first flux;

[0024] S3. Heating the dry material mixture of the first flux to 600°C-800°C for melting and dehydration treatment, stirring mechanically for 5-20 minutes, keeping it warm for 20-40 minutes, and obtaining the first flux after cooling;

[0025] S4. Crushing the first flux into particles with a particle diameter of 0.1-1 mm, subpackaging and sealing to obtain a finished product.

[0026] The components of the first flux are prepared in a blending manner, which can completely remove the moisture in the components of the first flux, and make the components of the first flux uniform...

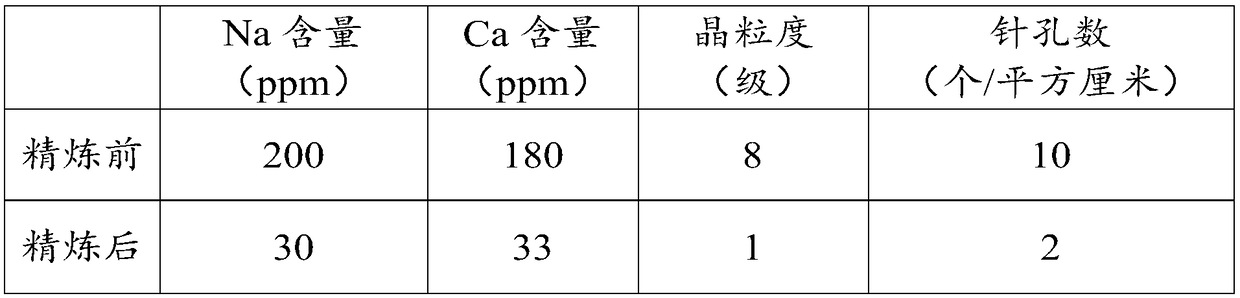

Embodiment 1

[0039] A flux for refining aluminum and aluminum alloy melts, the flux includes a first flux and a second flux. Wherein the composition of the first flux comprises by mass percent: K 3 AlF 6 10%, KCl 40%, MgCl 2 10%, Na 2 CO 3 30%, NaBF 4 10%; wherein the components of the second flux include: Na 2 TiF 6 55%, graphite powder 30%, mixed rare earth metal fluoride 15%.

[0040] The preparation method of the flux used for refining aluminum and aluminum alloy melts includes: preparing the first flux and the second flux respectively, wherein the components of the first flux are weighed according to the mass percentage, and then the components of the first flux are weighed. After preliminary mixing, a uniform dry material mixture of the first flux is prepared; then the dry material mixture of the first flux is placed in a graphite crucible and heated to 650°C for melting, and the molten state of the flux is mechanically stirred for 5 minutes with a tungsten tool. Keep war...

Embodiment 2

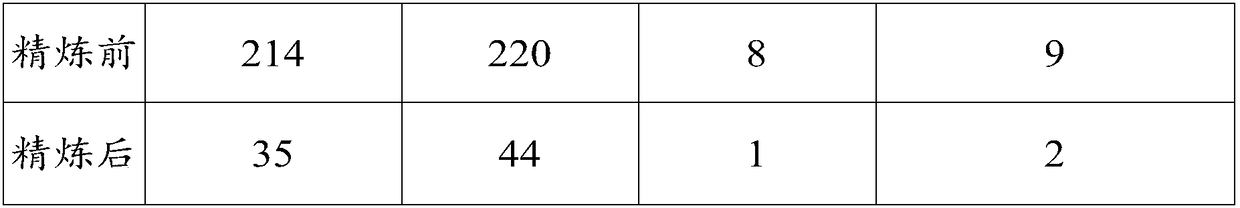

[0046] A flux for refining aluminum and aluminum alloy melts, the flux includes a first flux and a second flux. Wherein the first flux comprises by mass percentage: K 3 AlF 6 3%, K 2 AlF 5 10%, KAlF 4 5%, Na 2 AlF 5 2%, NaCl 25%, AlF 3 15%, Na 2 CO 3 35%, KBF 4 5%; Wherein the second flux comprises by mass percentage: Na 2 TiF 6 75%, graphite powder 10%, mixed rare earth metal fluoride 15%.

[0047] The preparation method of the flux used for refining aluminum and aluminum alloy melts includes: separately preparing the first flux and the second flux, wherein the components of the first flux are first broken and passed through 80-mesh sieves respectively. Secondly, weigh according to the mass percentage, preliminarily mix the weighed components, put them in a graphite crucible and heat up to 700°C to melt, use tungsten tools to mechanically stir the first flux in the molten state for 7 minutes, and keep it warm for 30 minutes . Crushing and sieving the cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com