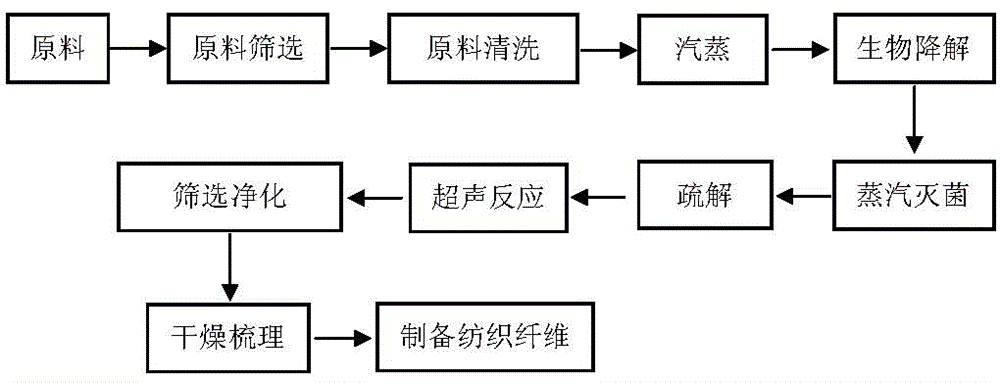

Method for biologically and ultrasonically preparing textile fibers

A textile fiber and ultrasonic technology, which is applied in the field of bio-ultrasonic preparation of textile fibers, achieves the effects of easy popularization and application, huge economic and social benefits, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention also can be realized by following method in concrete implementation:

[0032] (1), preparation of compound bacteria liquid:

[0033] Combine brown rot fungus: Acinetobacter ruckerii: Pseudomonas fluorescens: Rhinemeria tangshanus at a mass ratio of 2.2~2.8︰1.2~1.8︰1.2~1.8︰1.2~1.8, add water to form a flora Density is 6×10 7 more than one / ml compound bacteria solution;

[0034] (2), raw material washing and steaming:

[0035] Cut the hemp raw material into a length of 4-5cm, then wash it with water, enter the steaming chamber, steam and soften it for 10-30 minutes, and then enter the oblique spiral dehydrator for dehydration after the hemp raw material is softened;

[0036] (3), biodegradation:

[0037] The dehydrated hemp raw material is sent to the composite bacteria liquid warehouse, so that the composite bacterial group begins to biodegrade the lignin of the hemp raw material. The mass ratio of the dehydrated hemp raw material to the composi...

Embodiment 2

[0048] The present invention in concrete implementation, comprises the following steps:

[0049] (1), preparation of compound bacteria liquid:

[0050] Brown rot fungus: Acinetobacter ruckerii: Pseudomonas fluorescens: Rhinemeria tangshanensis with a mass ratio of 2.5︰1.5︰1.5︰1.5, adding water to make a colony density of 6×10 7 more than one / ml compound bacteria solution;

[0051] (2), wood chip washing and steaming:

[0052]Cut the raw wood chips into lengths of 3-4cm, then wash them with water, enter the steaming bin, steam and soften them for 10-30 minutes, and after the wood chips are softened, enter the oblique spiral dehydrator for dehydration;

[0053] (3), biodegradation:

[0054] Send the dehydrated wood chips to the composite bacteria liquid tank, let the composite bacteria group start to biodegrade the lignin of the wood chips, the mass ratio of the dehydrated wood chips to the composite bacteria liquid is 1:7, and the biodegradation temperature is 36~38℃ , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com