High-precision resonant optical voltage sensor and detecting method

An optical voltage, resonant technology, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problem of not completely eliminating temperature error, sensor miniaturization difficulty, error and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be described in detail below with reference to the drawings and specific embodiments.

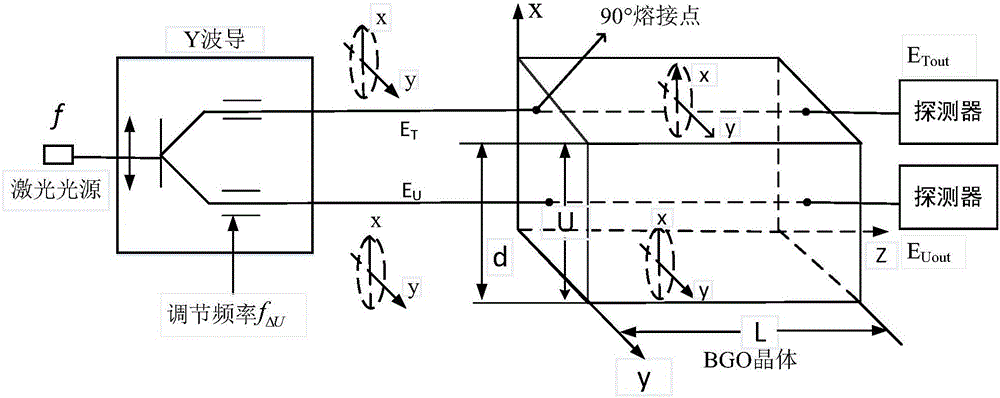

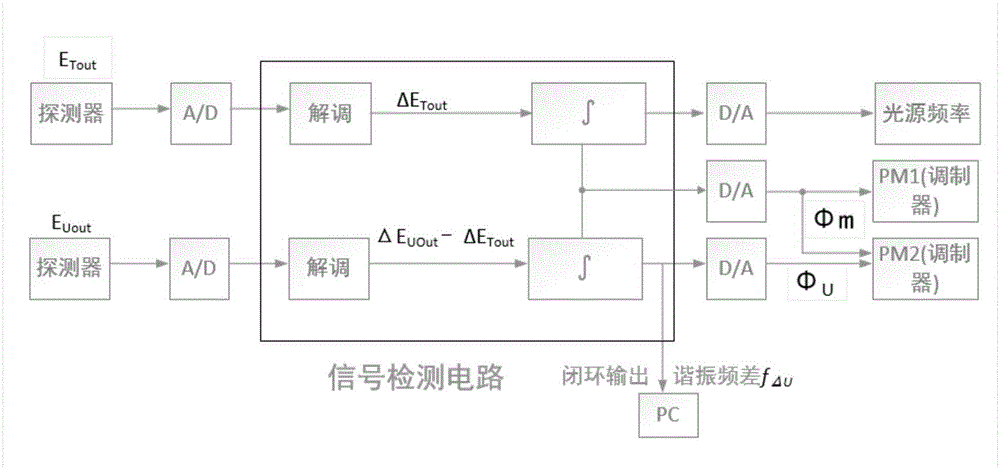

[0108] The high-precision resonant optical voltage sensor of the present invention, through the design of a dual-track resonant optical path, in which two linearly polarized light E U And E T Propagating along the BGO crystal, the temperature field of the two beams at the same time is the same, so the temperature change affects the polarization of the two paths E U And E T The interference caused is also consistent. Synchronously detect two beams of linearly polarized light E in the signal detection circuit U And E T Frequency difference of resonant frequency, linearly polarized light E caused by Pockels effect U The frequency difference information of the resonance frequency change is retained, linearly polarized light E U And E T The rest of the interference in the propagation of the BGO crystal cancels each other out;

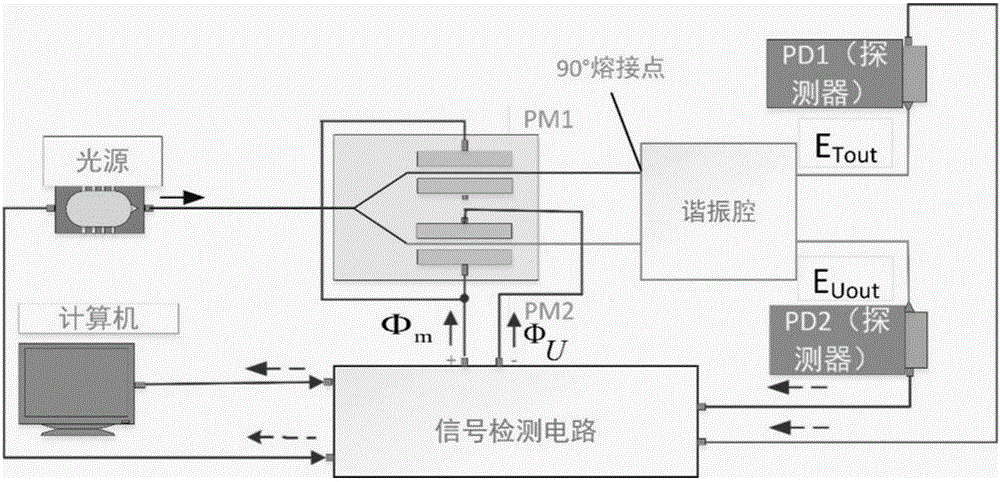

[0109] The high-precision resonant optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com