A kind of intergranular insulating high-silicon steel core and its preparation method

A high-silicon and high-silicon technology, applied to the high-silicon steel core with inter-particle insulation and its preparation field, can solve the problems of high eddy current loss and poor plastic toughness of the silicon-steel core, and achieve extended service life, high density, Avoiding the effect of plate thickness limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

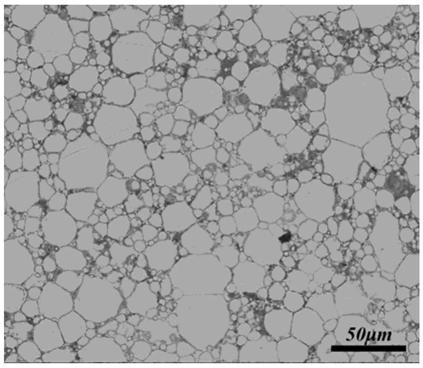

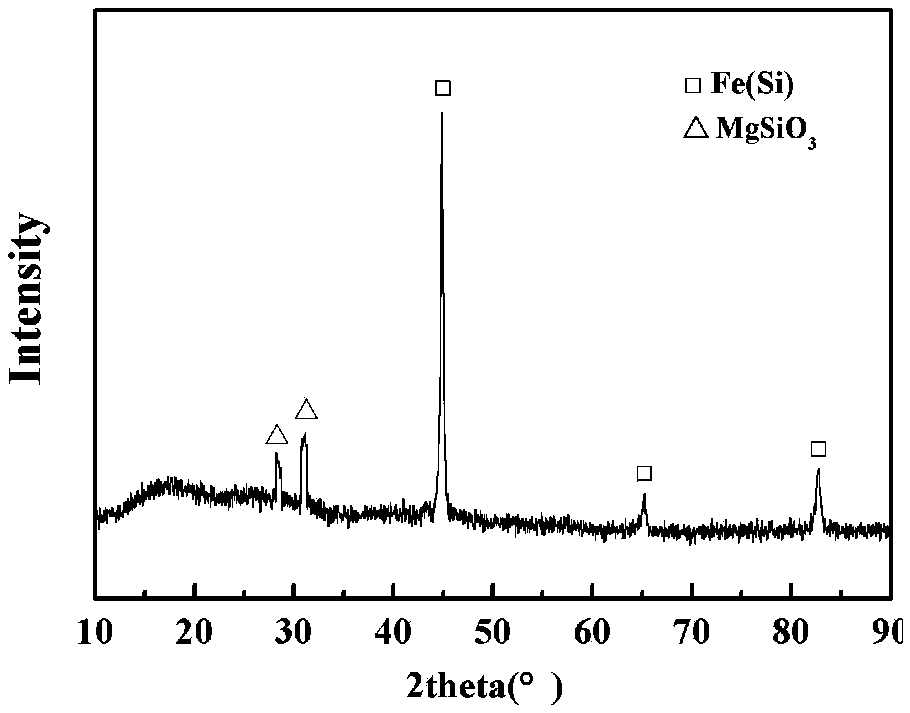

[0040] The preparation method of a high-silicon steel core with interparticle insulation in this embodiment first uses silicon powder to embed and siliconize the high-silicon iron-silicon alloy powder; then oxidizes the silicon-infiltrated high-silicon iron-silicon alloy powder treatment to form a layer of SiO on the surface of the high-silicon-iron-silicon alloy powder 2 Afterwards, the oxidized alloy powder is insulated and coated with inorganic oxides, and sintered to obtain a high-silicon steel core with inter-particle insulation. The specific steps are as follows:

[0041] The first step, embedding silicon infiltration of high-silicon-iron-silicon alloy powder

[0042] First mix 95wt% high-silicon-iron-silicon alloy powder and 5wt% silicon powder evenly, and then conduct heat treatment under the protection of nitrogen. High-silicon iron-silicon alloy powder after silicon.

[0043] The second step, the surface insulation coating of high-silicon-iron-silicon alloy powder ...

Embodiment 2

[0054] A kind of preparation method of the high-silicon steel core of intergranular insulation of the present embodiment, its specific steps are as follows:

[0055] The first step, embedding silicon infiltration of high-silicon-iron-silicon alloy powder

[0056] First mix 96wt% high-silicon-iron-silicon alloy powder and 4wt% silicon powder evenly, and then conduct heat treatment under the protection of argon. High-silicon iron-silicon alloy powder after silicon infiltration.

[0057] The second step, the surface insulation coating of high-silicon-iron-silicon alloy powder

[0058] Place the high-silicon-iron-silicon alloy powder embedded in silicon infiltration in a tubular annealing furnace, and carry out oxidation treatment in an air atmosphere. The oxidation treatment temperature is set at 450°C, and the holding time is 2 hours; , kept at 850° C. for 1 hour to obtain high-silicon-iron-silicon alloy powder with surface insulation coating. Among them: the mass ratio of hi...

Embodiment 3

[0064] A kind of preparation method of the high-silicon steel core of intergranular insulation of the present embodiment, its specific steps are as follows:

[0065] The first step, embedding silicon infiltration of high-silicon-iron-silicon alloy powder

[0066] First mix 98wt% high-silicon-iron-silicon alloy powder and 2wt% silicon powder evenly, and then conduct heat treatment under the protection of nitrogen. High-silicon iron-silicon alloy powder after silicon.

[0067] The second step, the surface insulation coating of high-silicon-iron-silicon alloy powder

[0068]Place the high-silicon-iron-silicon alloy powder embedded in silicon infiltration in a tubular annealing furnace, and carry out oxidation treatment in an air atmosphere. The oxidation treatment temperature is set at 600 ° C, and the holding time is 3 h; 2 o 3 The powder is kept under the protection of argon at 1050° C. for 1.5 hours to obtain a high-silicon-iron-silicon alloy powder with surface insulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com