Preparation method of nano array solar battery

A nano-array and solar cell technology, applied in the field of solar modules, can solve the problems of reducing photoelectric conversion efficiency, reducing the life of photo-generated carriers, and accelerating the recombination of photo-generated carriers, so as to improve photoelectric conversion efficiency, increase electron collection ability, Effect of improving photon utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the nano-array solar cell of the present embodiment comprises the following steps:

[0032] (1) De-damaging and texturing of the silicon wafer surface: place the silicon wafer in an aqueous solution of nitric acid, hydrofluoric acid, and texturing additives, and the texturing time is 0.8 minutes; The volume ratio of 40%, 11%, 0.3% is mixed, and the concentrations of nitric acid, hydrofluoric acid and texturing additives are the same.

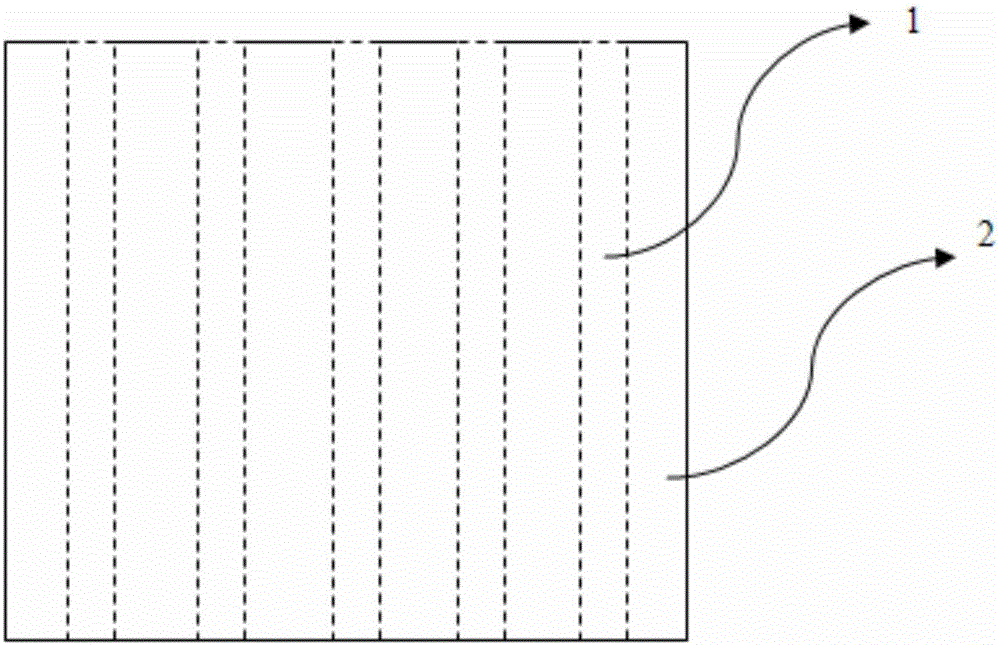

[0033] (2) Preparation of silicon wafer surface corrosion mask: use printing method to print negative polarity photoresist on the textured silicon wafer to prepare a surface corrosion mask, and the area 1 of the surface corrosion mask is as follows figure 1 As shown in , the thickness of the surface etching mask is 0.3 μm, and the width of the surface etching mask is 1.3 mm;

[0034] (3) Metal ion wet chemical catalytic corrosion nano-array preparation: the nano-array was prepared by hydrofluoric acid and silver...

Embodiment 2

[0043] The preparation method of the nano-array solar cell of the present embodiment comprises the following steps:

[0044] (1) De-damaging and texturing of the silicon wafer surface: place the silicon wafer in an aqueous solution of nitric acid, hydrofluoric acid, and texturing additives, and the texturing time is 0.8 minutes; The volume ratio of 40%, 11%, 0.3% is mixed, and the concentrations of nitric acid, hydrofluoric acid and texturing additives are the same.

[0045] (2) Preparation of silicon wafer surface corrosion mask: use printing method to print negative polarity photoresist on the textured silicon wafer to prepare a surface corrosion mask, and the area 1 of the surface corrosion mask is as follows figure 1 As shown in , the thickness of the surface etching mask is 0.3 μm, and the width of the surface etching mask is 1.3 mm;

[0046] (3) Metal ion wet chemical catalytic corrosion nano-array preparation: the nano-array was prepared by hydrofluoric acid and silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com