Preparation method of Fe-N-TiO2/13X molecular sieve photocatalyst

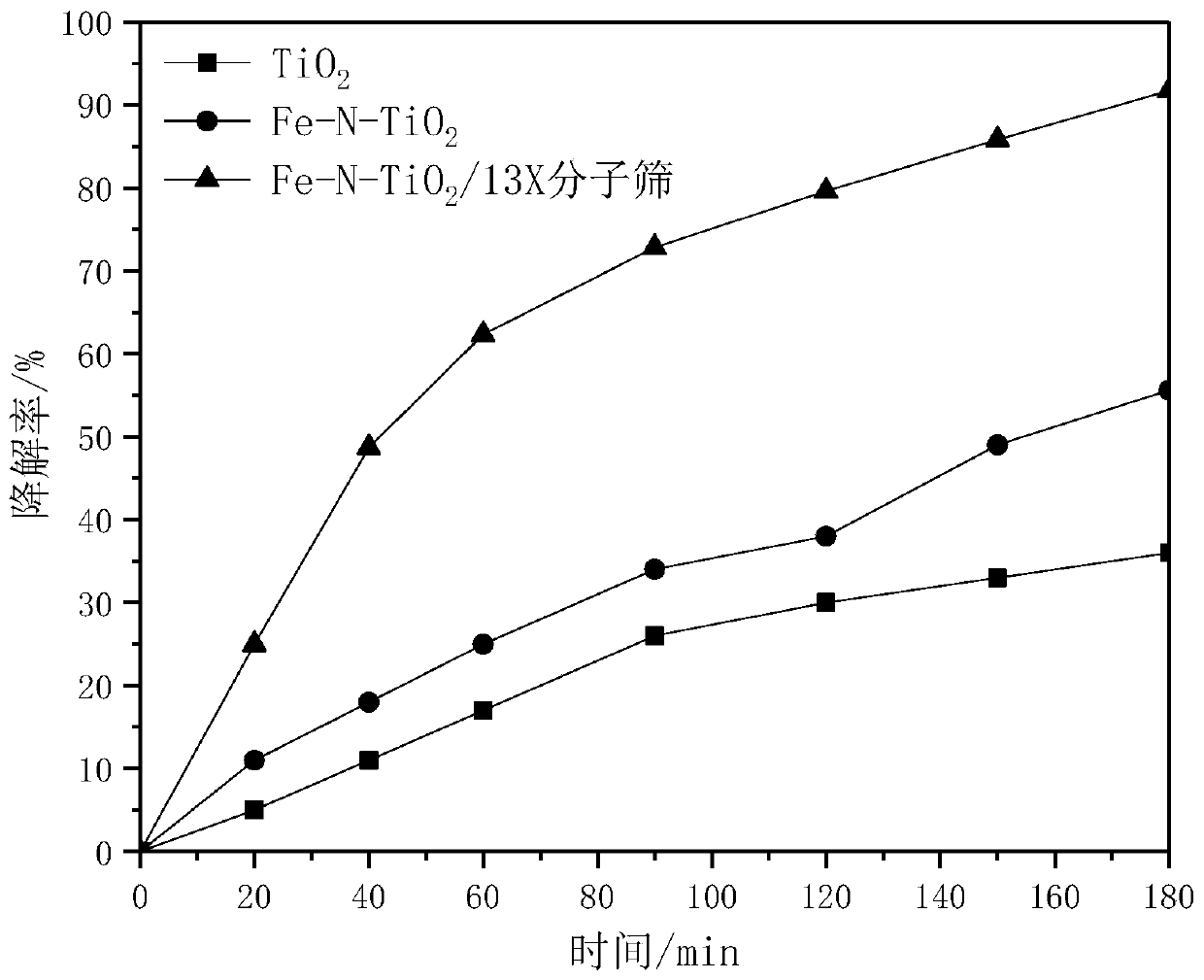

A technology of photocatalyst and molecular sieve, which is applied in the direction of molecular sieve catalyst, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problem of fast electron-hole recombination rate, low light utilization rate of photocatalyst, loss of active components of catalyst, etc. problem, to achieve the effect of improving photon utilization rate, improving adsorption performance and photocatalytic rate, and promoting electron-hole separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The Fe-N-TiO that this embodiment 1 provides 2 The preparation method of / 13X molecular sieve photocatalyst comprises the steps:

[0030] Step S1: Activate the 13X molecular sieve, grind the spherical 13X molecular sieve into powder particles, sieve to 40-60 mesh, and use the sieved molecular sieve powder with a mass concentration of 10% hydrochloric acid solution and 5% Soak in sodium hydroxide solution at room temperature, wash with ultrasonic vibration for 15 minutes, then rinse with distilled water several times, then put it in an oven for 10 hours at 100°C, and calcinate at 500°C for 1 hour in a muffle furnace to remove surface and channel impurities, take it out and cool it for later use;

[0031] Step S2: Fully mix 40ml of absolute ethanol, 10ml of acetic acid and 20ml of tetrabutyl titanate to form a clear solution after stirring. Weigh 20g of the activated molecular sieve powder into the above clear solution and stir to obtain A;

[0032] Step S3: take by weig...

Embodiment 2

[0036]The Fe-N-TiO that this embodiment 2 provides 2 The preparation method of / 13X molecular sieve photocatalyst comprises the steps:

[0037] Step S1: Activate the 13X molecular sieve, grind the spherical 13X molecular sieve into powder particles, sieve to 40-60 mesh, and use the sieved molecular sieve powder with a mass concentration of 10% hydrochloric acid solution and 5% Soak in sodium hydroxide solution at room temperature, wash with ultrasonic vibration for 15 minutes, then rinse with distilled water several times, then put it in an oven for 11 hours at 110°C, and calcinate at 520°C for 1.5 hours in a muffle furnace to remove surface and channel impurities, take it out and cool it for later use ;

[0038] Step S2: fully mix 60ml of absolute ethanol, 13ml of acetic acid and 30ml of tetrabutyl titanate, and then form a clear solution after stirring. Weigh 20g of activated molecular sieve powder into the above clear solution and stir to obtain A;

[0039] Step S3: take ...

Embodiment 3

[0043] The Fe-N-TiO that this embodiment 3 provides 2 The preparation method of / 13X molecular sieve photocatalyst comprises the steps:

[0044] Step S1: Activate the 13X molecular sieve, grind the spherical 13X molecular sieve into powder particles, sieve to 40-60 mesh, and use the sieved molecular sieve powder with a mass concentration of 10% hydrochloric acid solution and 5% Soak in sodium hydroxide solution at room temperature, clean with ultrasonic vibration for 15 minutes, then rinse with distilled water for several times, then put it in an oven for 12 hours at 120°C, calcinate at 550°C for 2 hours in a muffle furnace to remove surface and channel impurities, take it out and cool it for later use;

[0045] Step S2: fully mix 30ml of absolute ethanol, 7ml of acetic acid and 15ml of tetrabutyl titanate, and then form a clear solution after stirring. Weigh 20g of the activated molecular sieve powder into the above clear solution and stir to obtain A;

[0046] Step S3: take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com