A photocatalyst immobilization method and a method for continuously treating printing and dyeing wastewater

A technology for printing and dyeing wastewater and photocatalyst, applied in the field of environmental purification, can solve the problems of reducing the catalytic activity of titanium dioxide photocatalyst, unable to realize continuous treatment of wastewater, small catalytic contact area, etc., and achieves low cost, fast degradation speed and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

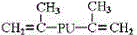

[0018] Dissolve 10g of polyurethane prepolymer with a molecular weight of 4000 in 74.5g of deionized water to form an emulsion, add 10g of nano-titanium dioxide P25 to the emulsion, stir at a high speed to make it mix evenly to form a stable suspension, and then add 5g of polyethylene glycol Acrylic ester and 0.5g N, N, N', N'-tetramethylethylenediamine, undergo emulsion free radical polymerization to form a large block of polyurethane hydrogel with immobilized photocatalyst, and cut the hydrogel to a side length of 3mm cubes, the immobilized photocatalyst is obtained.

[0019] The monolithic photocatalyst for printing and dyeing wastewater prepared in this example is filled in a cylindrical quartz glass reactor with a diameter of 100 mm, and the printing and dyeing wastewater is continuously fed in at a flow rate of 20 mL / min, and the printing and dyeing wastewater is kept in the container under sunlight The hydraulic retention time is 60 minutes. After the reaction is stable...

Embodiment 2

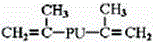

[0021] Dissolve 20g of a polyurethane prepolymer with a molecular weight of 3000 in 52g of deionized water to form an emulsion, add 20g of nano-titanium dioxide P25 to the emulsion, stir at a high speed to make it evenly mixed to form a stable suspension, and then add 7.5g of polyethylene glycol Acrylic ester and 0.5g N, N, N', N'-tetramethylethylenediamine, through emulsion free radical polymerization to form a large block of polyurethane hydrogel with immobilized photocatalyst, cut the hydrogel to a side length of 5mm cubes, the immobilized photocatalyst is obtained.

[0022] The monolithic photocatalyst for printing and dyeing wastewater prepared in this example is filled in a cylindrical quartz glass reactor with a diameter of 100 mm, and the printing and dyeing wastewater is continuously fed in at a flow rate of 20 mL / min, and the printing and dyeing wastewater is kept in the container under sunlight The hydraulic retention time is 60 minutes. After the reaction is stable...

Embodiment 3

[0024] Dissolve 15g of polyurethane prepolymer with a molecular weight of 5000 in 52g of deionized water to form an emulsion, add 25g of nano-titanium dioxide P25 to the emulsion, stir at a high speed to make it mix evenly to form a stable suspension, and then add 7.5g of N,N'-sub Methacrylic acid amide and 0.5 g of sodium sulfite were polymerized by emulsion free radicals to form a large block of polyurethane hydrogel immobilized with a photocatalyst, and the hydrogel was cut into cubes with a side length of 4 mm to obtain an immobilized photocatalyst.

[0025] The monolithic photocatalyst used for printing and dyeing wastewater prepared in this example is filled in a cylindrical quartz glass reactor with a diameter of 100mm, and the printing and dyeing wastewater is continuously fed into the printing and dyeing wastewater at a flow rate of 40mL / min, and the printing and dyeing wastewater is kept in the container under sunlight The hydraulic retention time is 30 minutes. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com