Electrospinning preparation method for cobaltosic oxide carbon nanometer fibers for sodium-n battery

A carbon nanofiber, sodium-ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology and other directions, can solve the problem of limiting the large-scale use of sodium-ion battery anode materials, reducing the rate performance of electrode materials, Problems such as low electron/ion conductivity, to achieve the effect of promoting penetration and electron/ion transfer, excellent charge and discharge rate performance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

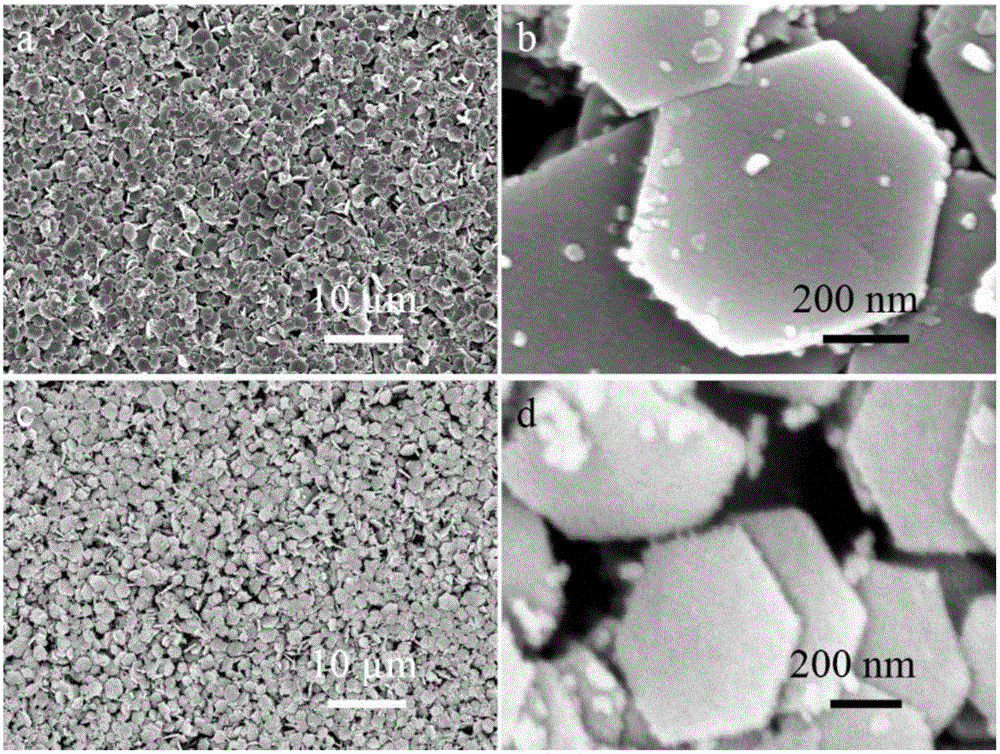

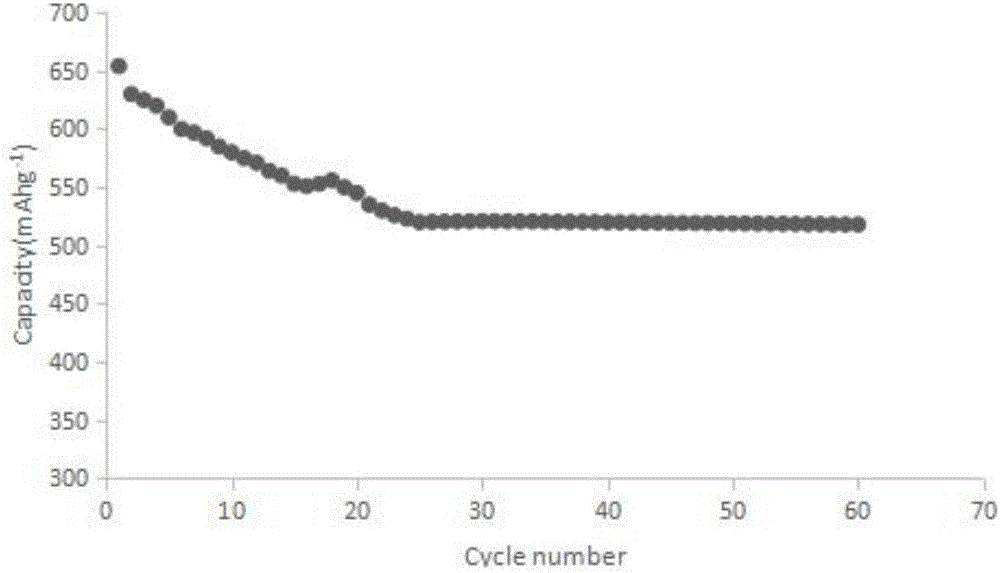

Image

Examples

Embodiment 1

[0020] Embodiment 1, sodium ion battery uses Co 3 o 4 An electrospinning preparation method for carbon nanofibers, comprising the following steps:

[0021] 1) Configuration of electrospinning precursor body fluid: Co 2+ The salt is dissolved in the mixed solution of deionized water and organic solvent according to the volume ratio of 1:1, Co 2+ The mass volume ratio of the quality of the salt to the mixed solution of deionized water and organic solvent is 0.14g / mL; then add polyvinylpyrrolidone (PVP) powder to the mixed solution, and stir to obtain a uniform electrospinning precursor liquid (PVP) is 0.08g / mL with the mass volume ratio of deionized water and organic solvent mixed solution;

[0022] The Co 2+ The salt is cobalt nitrate;

[0023] Described organic solvent is ethanol;

[0024] Described polyvinylpyrrolidone (PVP) molecular weight is 1,300,000;

[0025] 2) Preparation of Co by electrospinning 2+ Salt / PVP composite fiber membrane: electrospinning with the el...

Embodiment 2

[0031] Embodiment 2, sodium ion battery uses Co 3 o 4 An electrospinning preparation method for carbon nanofibers, comprising the following steps:

[0032] 1) Configuration of electrospinning precursor body fluid: Co 2+ The salt is dissolved in the mixed solution of deionized water and organic solvent according to the volume ratio of 1:1, Co 2+ The mass-volume ratio of the quality of the salt to the mixed solution of deionized water and organic solvent is 0.16g / mL; (PVP) is 0.10g / mL with the mass volume ratio of deionized water and organic solvent mixed solution;

[0033] The Co 2+ The salt is cobalt chloride;

[0034] Described organic solvent is methanol;

[0035] Described polyvinylpyrrolidone (PVP) molecular weight is 1,300,000;

[0036] 2) Preparation of Co by electrospinning 2+ Salt / PVP composite fiber membrane: electrospinning with the electrospinning precursor liquid obtained in step 1) to obtain Co 2+ Salt / PVP composite fiber membrane, spinning voltage 12kV; ...

Embodiment 3

[0041] Embodiment 3, sodium ion battery uses Co 3 o 4 An electrospinning preparation method for carbon nanofibers, comprising the following steps:

[0042] 1) Configuration of electrospinning precursor body fluid: Co 2+ The salt is dissolved in the mixed solution of deionized water and organic solvent according to the volume ratio of 1:1, Co 2+ The mass-volume ratio of the quality of the salt to the mixed solution of deionized water and organic solvent is 0.18g / mL; The mass volume ratio of (PVP) and deionized water and organic solvent mixed solution is 0.12g / mL;

[0043] The Co 2+ The salt is cobalt sulfate;

[0044] The organic solvent is N,N-dimethylformamide (DMF);

[0045] Described polyvinylpyrrolidone (PVP) molecular weight is 1,300,000;

[0046] 2) Preparation of Co by electrospinning 2+ Salt / PVP composite fiber membrane: electrospinning with the electrospinning precursor liquid obtained in step 1) to obtain Co 2+ Salt / PVP composite fiber membrane, the spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com