Alkane isomerization catalyst and preparation method thereof

A technology for alkane isomerization and catalysts, which is applied in the field of preparation of the above-mentioned catalysts, can solve the problems of no acidity, no charge that can be exchanged, limited application of catalytic reactions, etc., and achieve the effect of low reaction temperature and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

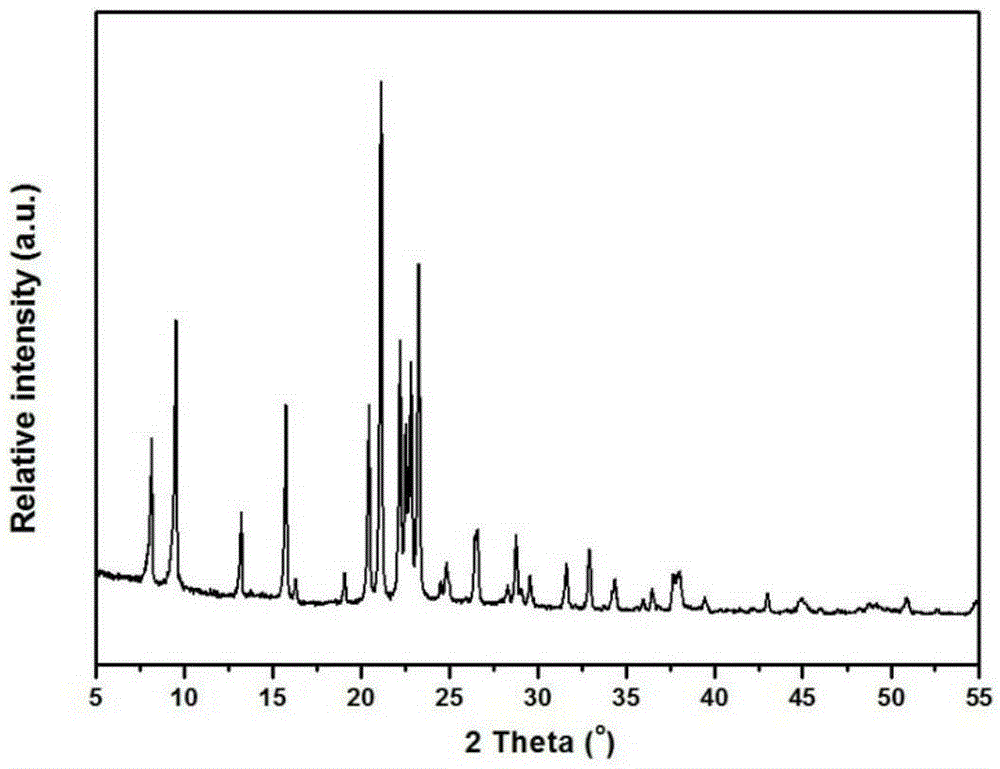

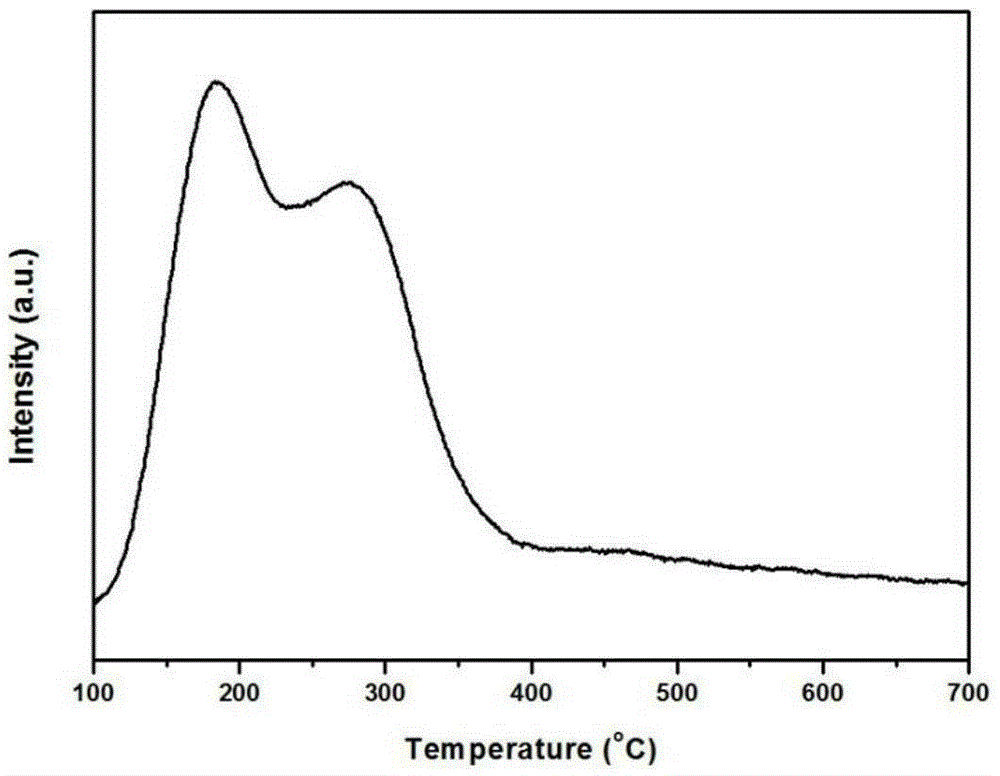

[0068] Weigh 70g of pseudo-boehmite, dissolve in 200g of deionized water, stir and mix evenly; weigh 130g of phosphoric acid, dissolve in 100g of deionized water, mix evenly; add the phosphoric acid solution dropwise to the pseudo-boehmite in a stirring state The solution forms a precursor mixture A; A is aged at 10°C for 4 hours; weigh 57g of diisopropylamine, add it dropwise to A, and stir evenly; then weigh about 45g of silica sol (30wt%), and add it dropwise to A , and stir evenly to form precursor mixture B; put B into a reaction kettle with a volume of 1L, and start crystallization at a temperature of 200°C for 24 hours; after the crystallization is completed, wash and filter the product until the filtrate is Neutral, the filtered product was dried in an oven at 120°C for 24 hours to obtain a silicon-aluminum phosphate composite molecular sieve SC1. Its X-ray diffraction spectrum is attached as image 3 , the acidic characterization results are attached Figure 4 The X...

Embodiment 2

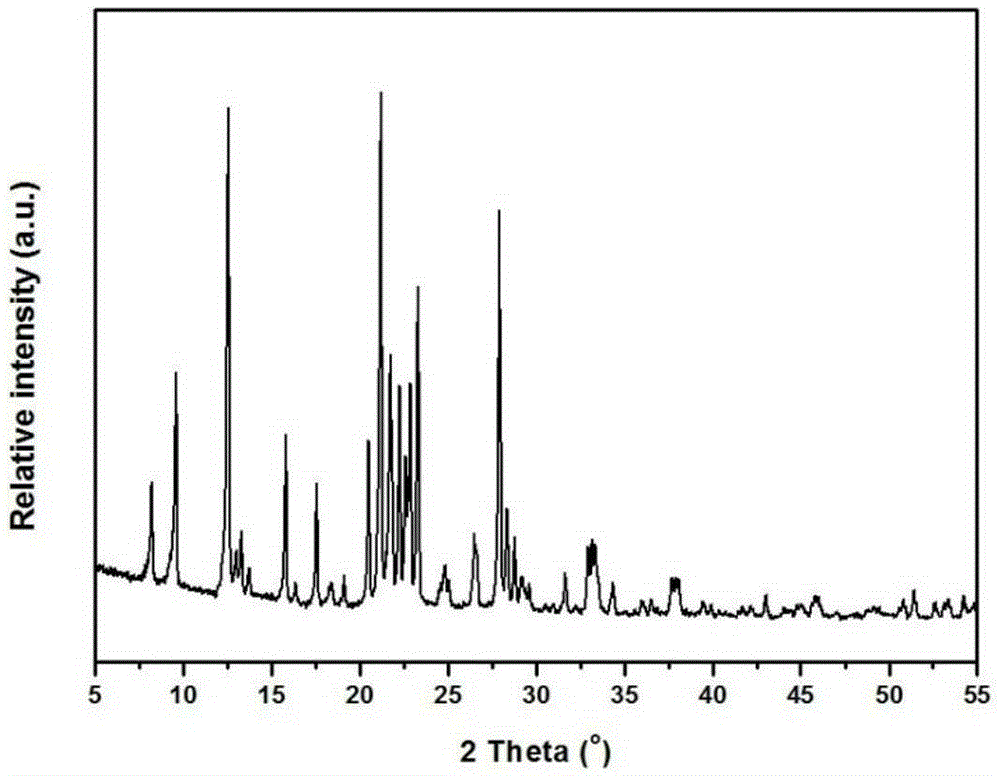

[0070] Weigh 70g of pseudo-boehmite, dissolve in 200g of deionized water, stir and mix evenly; weigh 130g of phosphoric acid, dissolve in 100g of deionized water, mix evenly; add the phosphoric acid solution dropwise to the pseudo-boehmite in a stirring state The solution forms a precursor mixture A; A is aged at 0°C for 2 hours; weigh 57g of di-n-propylamine, add it dropwise to A, and stir evenly; then weigh about 45g of silica sol (30wt%), and add it dropwise to A , and stir evenly to form precursor mixture B; put B into a reaction kettle with a volume of 1L, and start crystallization at a temperature of 200°C for 24 hours; after the crystallization is completed, wash and filter the product until the filtrate is Neutral, the filtered product was dried in an oven at 120°C for 20 hours to obtain a silicon-aluminum phosphate composite molecular sieve SC1. The X-ray diffraction peak positions are summarized in Table 2.

Embodiment 3

[0072] Weigh 70g of pseudo-boehmite, dissolve in 200g of deionized water, stir and mix evenly; weigh 130g of phosphoric acid, dissolve in 100g of deionized water, mix evenly; add the phosphoric acid solution dropwise to the pseudo-boehmite in a stirring state The solution forms a precursor mixture A; A is aged at 0°C for 8 hours; weigh 57g of di-n-propylamine, add it dropwise to A, and stir evenly; then weigh about 23g of silica sol (30wt%), and add it dropwise to A , and stir evenly to form precursor mixture B; put B into a reaction kettle with a volume of 1L, and start crystallization at a temperature of 200°C for 24 hours; after the crystallization is completed, wash and filter the product until the filtrate is Neutral, the filtered product was dried in an oven at 120°C for 18 hours to obtain a silicon-aluminum phosphate composite molecular sieve SC1. The X-ray diffraction peak positions are summarized in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com