A kind of high mullite crystal phase ceramic slurry

A technology of ceramic slurry and mullite, applied in the field of ceramic slurry, can solve the problems of reducing the yield rate, pollution, environmental harm, etc., and achieve the effects of improving the yield rate of finished products, reducing environmental pollution, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

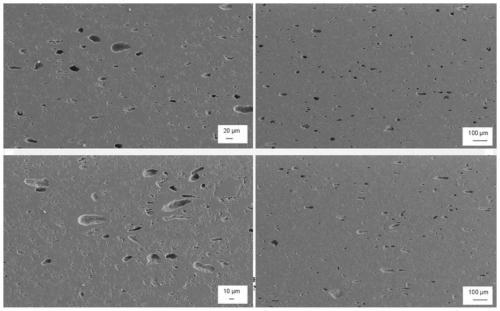

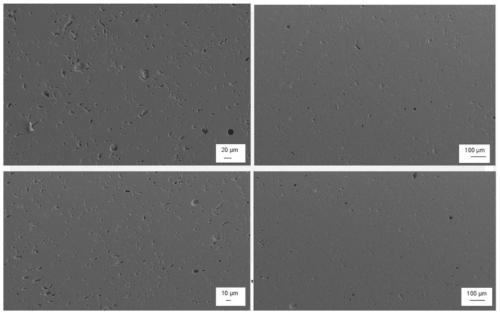

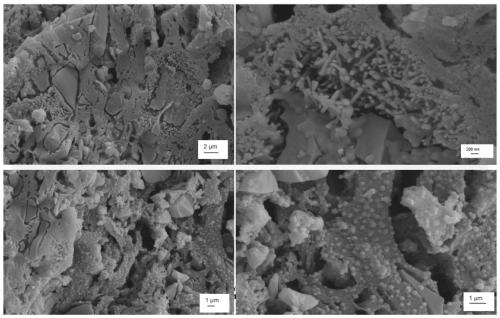

Image

Examples

Embodiment

[0025] Embodiment: Sodium stone powder, pyrophyllite, feldspar, ball clay, kaolin, illite weathered clay, dolomite, and waste porcelain powder are proportioned according to the weight ratio in Table 1, and the slurry is obtained by ball milling, and the mold is used Grouting, green body molding, drying, and high-temperature firing to obtain products, wherein the formula numbered 7 is the formula of the existing ceramic slurry.

[0026]

[0027] Table 1

[0028] Wherein, the chemical composition content of the blank of above-mentioned each embodiment is (see table 2 below):

[0029] Numbering SiO 2

[0030] Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com