A kind of preparation method of modified graphene reinforced polyurethane sponge for oil-water separation

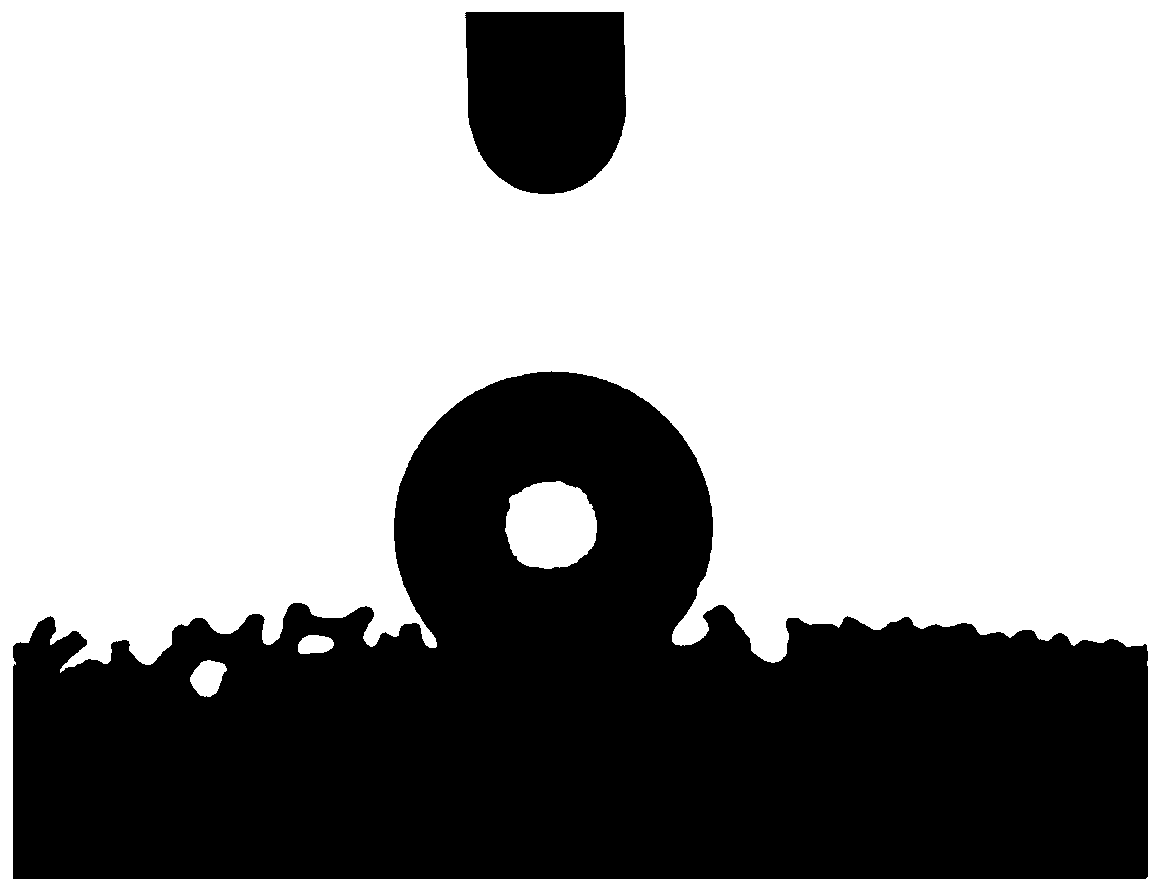

A polyurethane sponge, oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high cost, difficult to popularize and utilize, expensive carbon nanotubes, etc., and achieves good reusability, easy operation, The effect of high-efficiency water-oil separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare 100mL of graphene oxide dispersion with a concentration of 1mg / mL, ultrasonicate (400W power, 40kHz frequency) for 2 hours to make it evenly dispersed, and alternately add Tris and 10mM HCl to adjust its pH to 8.5;

[0029]Take 100 mg of dopamine and add it to the above-mentioned dispersion, ultrasonically react at room temperature (power 400W, frequency 40kHz) for 2 hours, centrifuge to collect the reaction product, wash twice with deionized water and ethanol respectively, and dissolve in 100mL ethanol;

[0030] Then add 480mg 1H,1H,2H,2H-perfluorodecyl mercaptan (PFDT), react at room temperature for 24 hours, collect the reaction product by centrifugation, and place it in a drying oven at 50°C for 4 hours to obtain the improved Graphene powder;

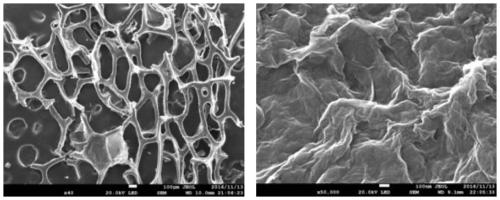

[0031] Dissolve 4 mg of the above powder in 5 mL of ethanol to prepare an infusion solution, soak 10 mg of a clean commercially available polyurethane sponge in it, oscillate ultrasonically (power 400 W, frequency 40 ...

Embodiment 2

[0034] Prepare 100 mL of graphene oxide dispersion with a concentration of 1 mg / mL, ultrasonically (power 400 W, frequency 40 kHz) for 2 hours to make it evenly dispersed, and alternately add Tris and 10 mm of HCl to adjust its pH to 8.5;

[0035] Take 100 mg of dopamine and add it to the above-mentioned dispersion liquid, react with ultrasound (power 400W, frequency 40kHz) at room temperature for 2 hours, collect the reaction product by centrifugation, wash twice with deionized water and ethanol respectively, and replace the solvent with ethanol at the same time;

[0036] Then add 720mg 1H, 1H, 2H, 2H-perfluorodecyl mercaptan (PFDT), react at room temperature for 24 hours, collect the reaction product by centrifugation, and place it in a drying oven at 50°C for 4 hours to obtain the improved Graphene powder;

[0037] Dissolve 5 mg of the above powder in 5 mL of ethanol to prepare an infusion solution, soak 10 mg of a clean commercially available polyurethane sponge in it, osc...

Embodiment 3

[0040] Prepare 100 mL of graphene oxide dispersion with a concentration of 1 mg / mL, ultrasonically (power 400 W, frequency 40 kHz) for 2 hours to make it evenly dispersed, and alternately add Tris and 10 mm of HCl to adjust its pH to 8.5;

[0041] Take 150 mg of dopamine and add it to the above-mentioned dispersion liquid, react with ultrasound (400W power, 40kHz frequency) at room temperature for 2 hours, collect the reaction product by centrifugation, wash twice with deionized water and ethanol respectively, and replace the solvent with ethanol at the same time;

[0042] Then add 270mg of octadecylamine (ODA), react at room temperature for 24 hours, collect the reaction product by centrifugation, and place it in a drying oven at 50°C for 4 hours to obtain a modified graphene powder;

[0043] Dissolve 8 mg of the above powder in 5 mL of ethanol to prepare an infusion solution, soak 10 mg of a clean commercially available polyurethane sponge in it, oscillate ultrasonically (pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com