Nitrogen-doped and carbon-coated iron trioxide anode material for lithium ion battery and preparation method of nitrogen-doped and carbon-coated iron trioxide anode material

A technology for ferric oxide and lithium ion batteries, which is applied in the field of electrochemical power sources, can solve the problems of ferric oxide easy to powder and agglomerate, decrease battery cycle performance, unfavorable electron transport, etc., and achieves good application prospects and easy preparation process. Amplified, high cycle capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, the nitrogen-doped carbon-coated ferric oxide lithium ion battery negative electrode material was prepared according to the following steps:

[0041] A. Add ferric chloride hexahydrate and sodium dihydrogen phosphate dihydrate into 300mL water to obtain a reaction solution; the concentration of ferric chloride in the reaction solution is 0.02mol / L, and the concentration of sodium dihydrogen phosphate is 0.45mmol / L L;

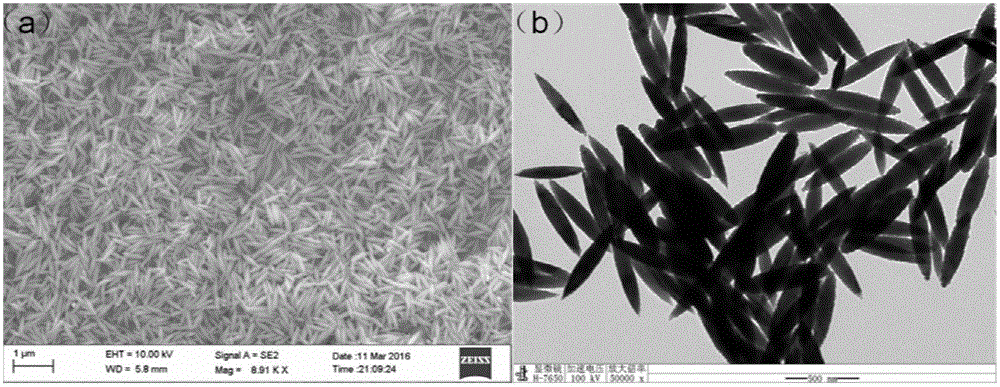

[0042] Add the reaction solution into the reaction kettle, conduct a hydrothermal reaction at 105°C for 48 hours, cool down to room temperature naturally, centrifuge and wash to obtain the nano-spindle-shaped ferric oxide.

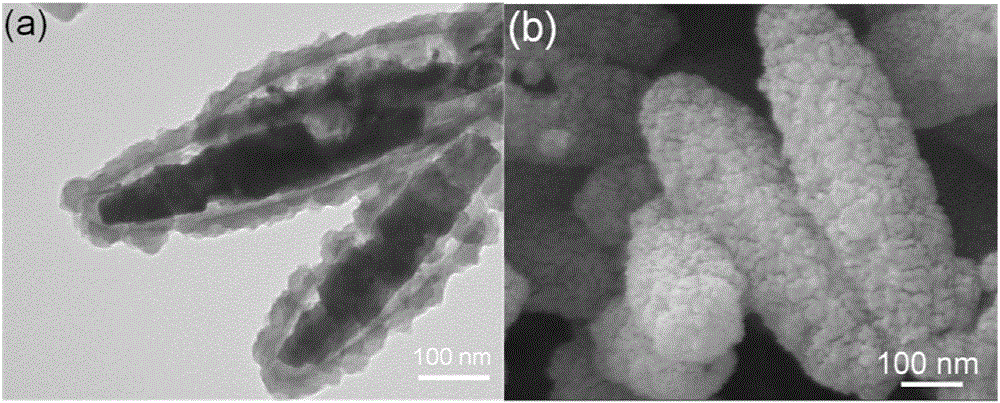

[0043] B. Disperse 50mg of nano-spindle-shaped ferric oxide in 200mL of a mixture of isopropanol and water at a volume ratio of 4:1, stir ultrasonically for 30min, and then add 2mL of ammonia and 0.2mL of orthosilicate Ethyl ester, continue to stir for 4h, centrifuge and wash to obtain the spindle precursor Fe 2 o ...

Embodiment 2

[0053] In this example, the nitrogen-doped carbon-coated ferric oxide lithium ion battery negative electrode material was prepared according to the following steps:

[0054] A. Add ferric chloride hexahydrate and sodium dihydrogen phosphate dihydrate into 300mL water to obtain a reaction solution; the concentration of ferric chloride in the reaction solution is 0.02mol / L, and the concentration of sodium dihydrogen phosphate is 0.45mmol / L L;

[0055] Add the reaction solution into the reaction kettle, conduct a hydrothermal reaction at 105°C for 48 hours, cool down to room temperature naturally, centrifuge and wash to obtain the nano-spindle-shaped ferric oxide.

[0056] B. Disperse 50mg of nano-spindle-shaped ferric oxide in 200mL of a mixture of isopropanol and water at a volume ratio of 4:1, stir ultrasonically for 30min, and then add 2mL of ammonia and 0.3mL of orthosilicate Ethyl ester, continue to stir for 4h, centrifuge and wash to obtain the spindle precursor Fe 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis length | aaaaa | aaaaa |

| Minor axis length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com