Pesticide composition containing diflufenican, flufenacet and flucarbazone-sodium and application of pesticide composition

A technology of diflufenican and a pesticide composition, which is applied in the field of pesticides, can solve the problems of poor control effect and difficulty in effectively controlling the damage of wheat weeds, and achieve the effects of prolonging the service life, reducing adverse effects, and improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

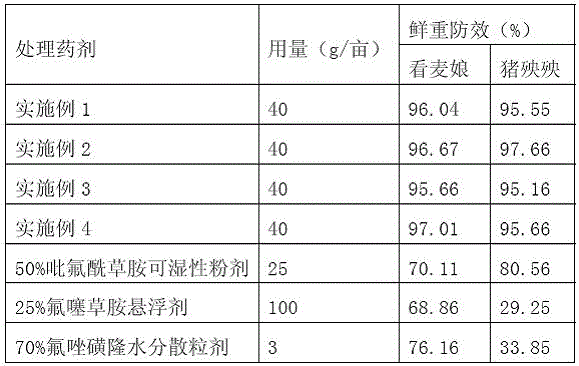

Examples

Embodiment 1)

[0025] 22% diflufenic acid flufenacet flufenazole oil suspension: diflufenic acid 5%, flufenacet 15%, flufenazone 2%, phenethylphenol polyoxyethylene 5% ether, 8% sodium lignosulfonate, 5% epoxy soybean oil, 5% organic bentonite, and 100% methyl oleate.

[0026] After mixing flufenacet with the solvent, add other materials (except organic bentonite) into the reactor mixer, stir evenly, and inject the materials into a multi-stage sand mill for grinding. The fineness of the ground materials is 98% After passing through 1-5μm, the material is discharged, and the material is put into a high-shear emulsification kettle together with the pre-dissolved organic bentonite. After emulsification, it can be made into 22% diflufenican, flufenacet, and fluoxasulfuron. oil suspension.

Embodiment 2)

[0028] 57% Diflufenamide · Flufenacet · Flucarbazone Water Suspension Concentrate: Diflufenamide 15%, Flufenacet 40%, Flufenacet 2%, Phenethylphenol Polyoxyethylene Ether 5%, sodium lignosulfonate 8%, ethylene glycol 5%, magnesium aluminum silicate 2%, silicone defoamer 0.5%, preservative 0.1%, xanthan gum 0.1%, water to 100%.

[0029] After mixing flufenacet with water, add other materials (except xanthan gum) into the reactor mixer together, stir evenly, inject the materials into a multi-stage sand mill for grinding, and the fineness of the ground materials is 98 %After passing through 1-5μm, the material is discharged, and the material is put into a high-shear emulsification kettle together with the pre-dissolved xanthan gum. After emulsification, 57% diflufenican, flufenacet, and flufenazole can be made Sulfonuron Suspended Concentrate.

Embodiment 3)

[0031] 67% Diflufenamide · Flufenacet · Flufenazone WP: Diflufenamide 25%, Flufenacet 40%, Flufenacet 2%, Sodium Lauryl Sulfate 2 %, sodium butylnaphthalene sulfonate 3%, calcium lignosulfonate 5%, white carbon black 5%, kaolin to 100%.

[0032] After flufenacet is adsorbed and mixed with the filler, it is added to the conical mixer together with other materials and mixed evenly, and then pulverized by the jet mill, and the pulverized material is then mixed by the conical mixer, and the fineness of the mixed material is 98 % Pass through a 325 mesh standard sieve to obtain 67% diflufenican · flufenacet · flucarbazone wettable powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com