Coal-fired flue gas demercuration method employing additive and adsorbent

A technology of coal-fired flue gas and additives, which is applied in the fields of air pollution control, energy conservation and environmental protection, can solve the problems of limited adsorption capacity enhancement, cost reduction, and dosage reduction, and achieves low cost, convenient operation and high mercury removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

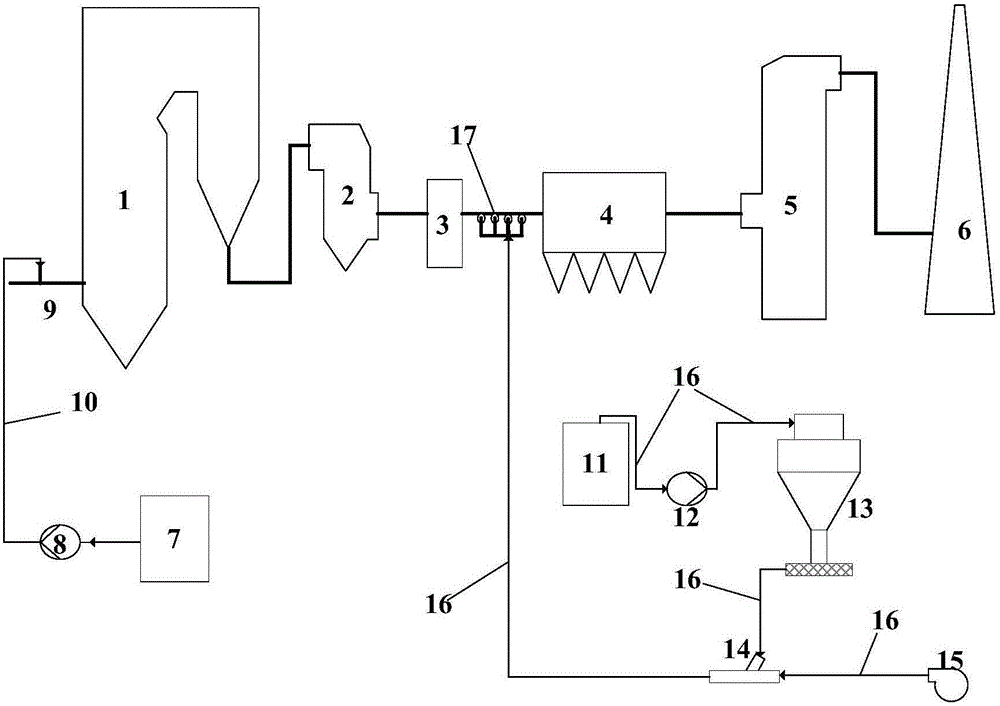

[0026] The mercury removal test of the present invention was carried out in a 300MW unit coal-fired power plant. The coal-fired unit was equipped with flue gas purification devices such as SCR, ESP, and WFGD. First, the total mercury concentration in the flue gas at the boiler outlet was measured to be 8.56 μg / m 3 , where Hg 0 The concentration ratio is 39.5%, and the total mercury concentration in the chimney inlet flue gas is 4.74μg / m 3 , with a benchmark overall mercury removal efficiency of 44.6%. Secondly, measure the mercury removal rate when the additive solution is added separately, and the additive adopts 5mol / L CaBr 2 Solution, the addition amount is 44L / h, after the test is stable, the Hg in the flue gas at the boiler outlet is measured 0 The concentration ratio is 11.8%, indicating about 70% Hg 0 To Hg 2+ conversion, while the total mercury concentration in the flue gas at the chimney inlet is 0.84 μg / m 3, compared with the baseline condition, the total mercur...

Embodiment 2

[0029] In a 300MW unit coal-fired power plant, the mercury removal test of the present invention is carried out, and the additive is 1mol / LCaBr 2 solution, the addition amount is 22L / h, the adsorbent adopts the mixture of activated carbon and Br-loaded activated carbon, and its mass mixing ratio is 1:1, wherein the Br load in the Br-loaded activated carbon is 10wt%, and the mixing ratio of the two adsorbents is 0.2 : 1~0.8:1, the injection amount of adsorbent is injected with the weight ratio of adsorbent to mercury in the flue gas of 1900:1, and the rest of the conditions are the same as in Example 1. After the test is stabilized, the total mercury concentration in the flue gas at the chimney inlet is measured to be 0.60 μg / m 3 , compared with the baseline condition, the total mercury concentration was reduced by 87.1%, and its total mercury removal efficiency reached 93.0%.

Embodiment 3

[0031] The mercury removal test of the present invention is carried out in a 300MW unit coal-fired power plant, and the additive uses NaBrO 3 and KBrO 3 Mixed solution, the mixing ratio is 0.2:1 ~ 0.8:1, the total concentration of the mixed solution is 2mol / L, and the addition amount is 40L / h. The adsorbent is a mixture of activated carbon and Br-loaded activated carbon, and the mass mixing ratio is 1:1. Among them, the Br loading in the Br-loaded activated carbon is 10wt%, the mixing ratio of the two adsorbents is 0.2:1-0.8:1, and the adsorbent injection volume is sprayed at a weight ratio of adsorbent to mercury in the flue gas of 1900:1, and the rest The conditions are the same as in Example 2. After the test was stabilized, the total mercury concentration in the flue gas at the chimney inlet was 0.62 μg / m3. Compared with the reference condition, the total mercury concentration was reduced by 86.9%, and the total mercury removal efficiency reached 92.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com