Method for preparing anti-pollution forward-permeating polyamide composite film through aftertreatment

A forward osmosis, polyamide technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of forward osmosis polyamide membrane being easily contaminated by organic compounds, reducing the processing efficiency of forward osmosis process, etc. Anti-fouling performance, maintaining selectivity, effect of low catalyst amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

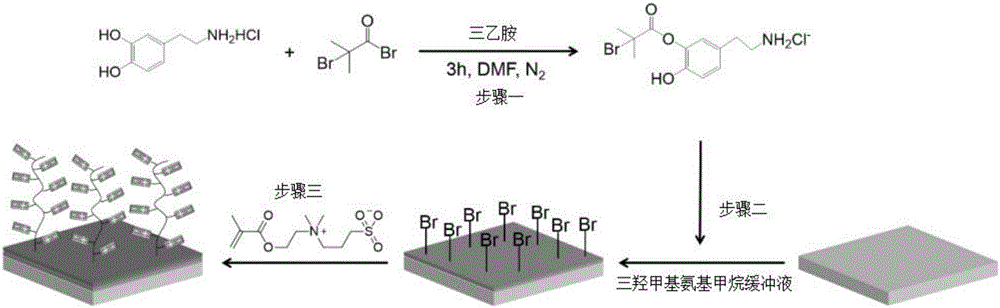

[0017] Specific embodiment 1: This embodiment is a post-treatment method for preparing anti-pollution forward osmosis polyamide composite membrane, which is specifically completed according to the following steps:

[0018] 1. Coupling: Dissolve dopamine hydrochloride in dimethylformamide, then add 2-bromoisobutyryl bromide and triethylamine under nitrogen protection, and stir and react for 2h-6h under nitrogen protection to obtain a coupling solution;

[0019] 2. Grafting initiator: add tris buffer solution to the coupling solution to obtain a mixed solution, and then immerse the active layer on the surface of the forward osmosis polyamide composite membrane in the mixed solution, and ensure the forward osmosis polyamide composite The support layer on the membrane surface is not in contact with the mixed solution, and the immersion time is 10 min to 90 min, to obtain the graft initiator forward osmosis polyamide composite membrane;

[0020] 3. Graft zwitterionic polymer: dissolve zwi...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and embodiment 1 is: in step 1, dopamine hydrochloride is dissolved in dimethylformamide, and then nitrogen is introduced, and 2-bromoisobutyryl bromide is added under the protection of nitrogen. And triethylamine, and stirred for 3h under the protection of nitrogen to obtain a coupling solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: This embodiment is different from one of specific embodiments one or two in that the volume ratio of the mass of dopamine hydrochloride and the volume of dimethylformamide described in step one is 800 mg:40 mL. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com