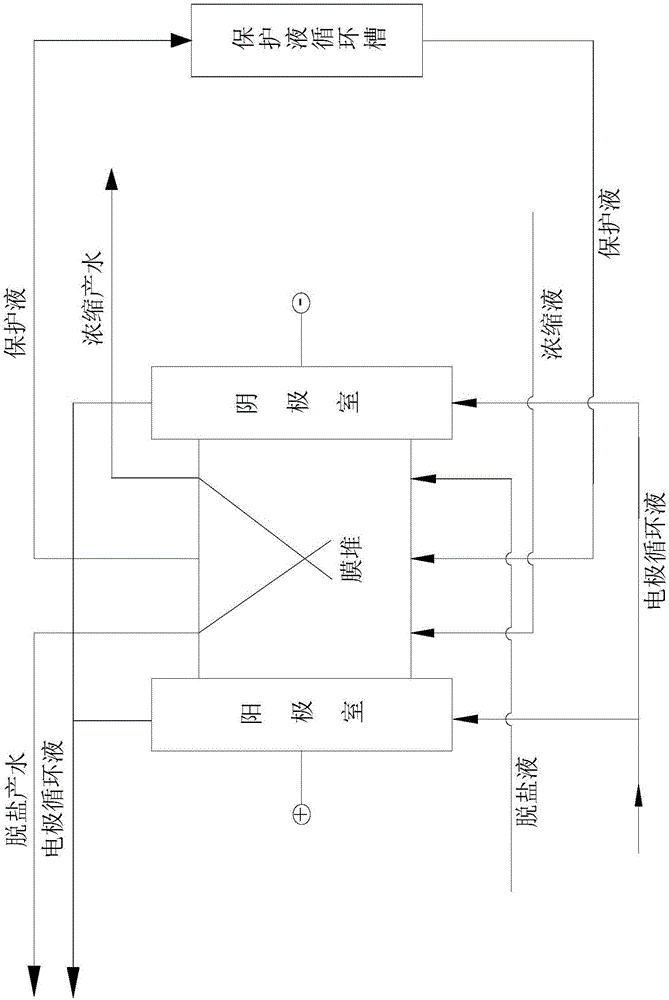

Electrodialysis device

A technology of electrodialysis and positive membrane, applied in electrodialysis, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of no use value, increase of separation cost, high separation cost, etc., to ensure long-term stable operation , mitigation of discharge or reuse issues, effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

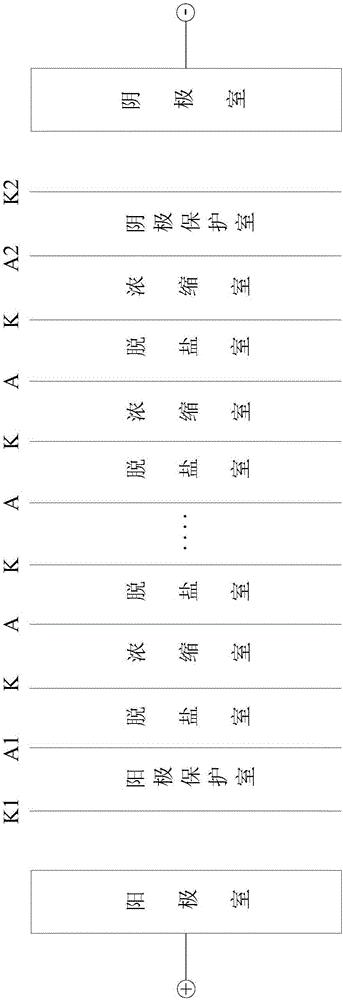

[0046] In Example 1, both the first positive film K1 and the second positive film K2 are resistant to Cl 2 The corrosion-enhanced positive membrane, the first negative membrane A1 and the second negative membrane A2 are all A192 type membranes, the anion exchange membrane A is all ACS type membranes, and the cation exchange membrane K is all CIMS type membranes.

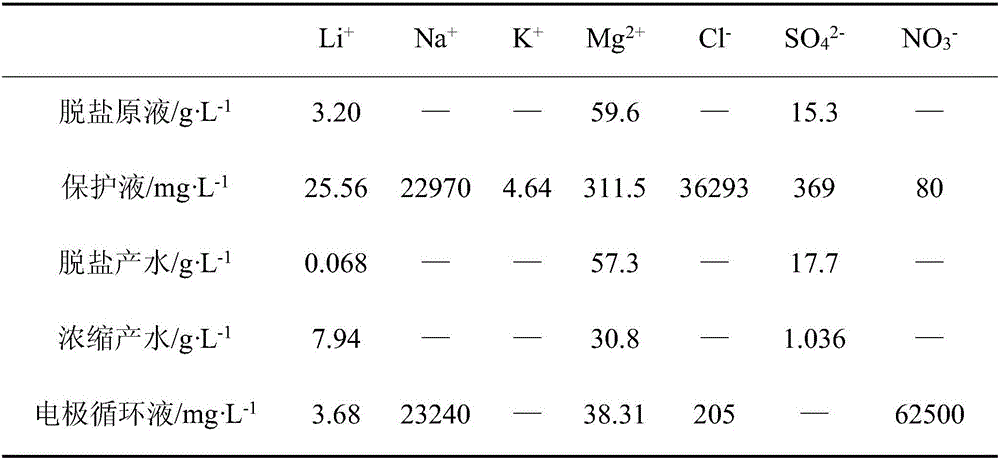

[0047] The inlet water of the protective solution is 1mol / LNaCl, and its inlet volume is 3L; the main composition of the desalination stock solution is shown in Table 1, and its inlet volume is 4.5L; the inlet volume of the concentrated solution is 0.95L; the electrode solution is 1mol / L NaNO 3 with 0.01mol / LHNO 3 The mixed solution, whose entry volume is 2L; the main composition of the protection solution is shown in Table 1.

[0048] During the electrodialysis process, the average current density is controlled to be 210A m -2 , and control the superficial linear velocity of the protective solution in the anode p...

Embodiment 2

[0055] In embodiment 2, the first positive membrane K1 is a CIMS type membrane with an additional protective layer N801 on its outside, the second positive membrane K2 and the cation exchange membrane K are all CIMS type membranes, the first negative membrane A1 and the second negative membrane A2 All are AMX type membranes, and the anion exchange membrane A is all ACS type membranes.

[0056] The inlet volume of the protection solution is 1mol / LNaCl, and its inlet volume is 3L; the main composition of the desalination stock solution is shown in Table 2, and its inlet volume is 4.5L; the inlet volume of the concentrated solution is 0.95L; the electrode solution is 1mol / L NaNO 3 with 0.01mol / LHNO 3 The mixed solution, whose entry volume is 2L; the main composition of the protective solution is shown in Table 2.

[0057] During the electrodialysis process, the average current density is controlled to be 210A m -2 , and control the superficial linear velocity of the protective...

Embodiment 3

[0063] In Example 3, both the first positive film K1 and the second positive film K2 are resistant to Cl 2 The corrosion-enhanced positive membrane, the first negative membrane A1, the second negative membrane A2 and the anion exchange membrane A are all ACS type membranes, and the cation exchange membrane K is all CIMS type membranes.

[0064] Protection solution inlet water is 0.25mol / LNa 2 SO 4 , its entry volume is 3L; the main composition of the desalination stock solution is shown in Table 3, its entry volume is 4.5L; the entry volume of the concentrated solution feedwater is 0.95L; the electrode solution is 0.5mol / L 2 SO 4 and 0.005mol / L H 2 SO 4 The mixed solution, whose entry volume is 2L; the main composition of the protective solution is shown in Table 3.

[0065] During the electrodialysis process, the average current density is controlled to be 210A m -2 , and control the superficial linear velocity of the protective solution in the anode protection chamber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com