Super-hydrophobic and super-oleophylic cellulose sponge as well as preparation method and application thereof

A cellulose sponge and super lipophilic technology, which is applied in the field of marine oil spill treatment and functional materials, can solve the problems of acid and alkali resistance, complex process, and fragile substrate, etc., to reduce surface energy, simple preparation method, and not easy to fall off with the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A kind of preparation method of superhydrophobic-superoleophilic cellulose sponge provided by another aspect of the embodiment of the present invention comprises:

[0048] Provide porous cellulose sponge;

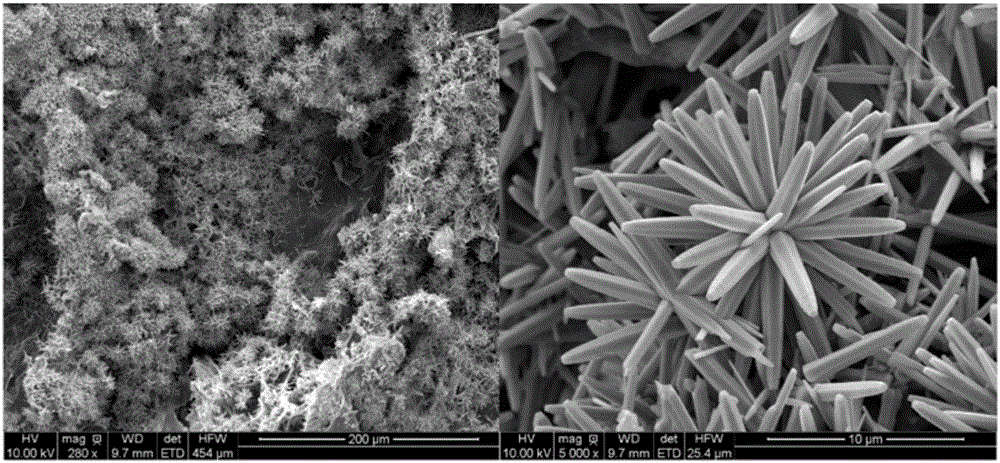

[0049] Immersing the porous cellulose sponge in a solution containing zinc salt, so that the porous cellulose sponge grows to form a ZnO micro-nano structure, and obtains a ZnO / cellulose sponge;

[0050] The ZnO / cellulose sponge is contained in the silane hydrolyzate solution containing lipophilic and hydrophobic groups, so that -Si(OH) in the silane hydrolyzate 3 At least chemically bond with the hydroxyl groups on the ZnO micro-nanostructures in the ZnO / cellulose sponge, thereby at least grafting lipophilic and hydrophobic groups on the ZnO micro-nanostructures to obtain the superhydrophobic-superoleophilic cellulose sponge.

[0051] In some more preferred embodiments, the preparation method may also include: after processing the porous cellulose sponge into a de...

Embodiment 1

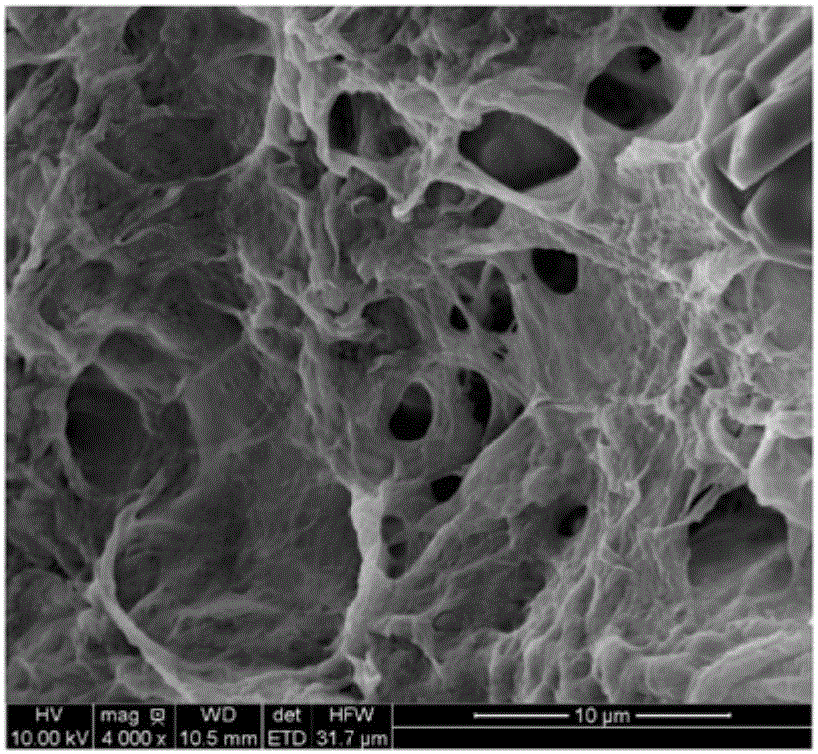

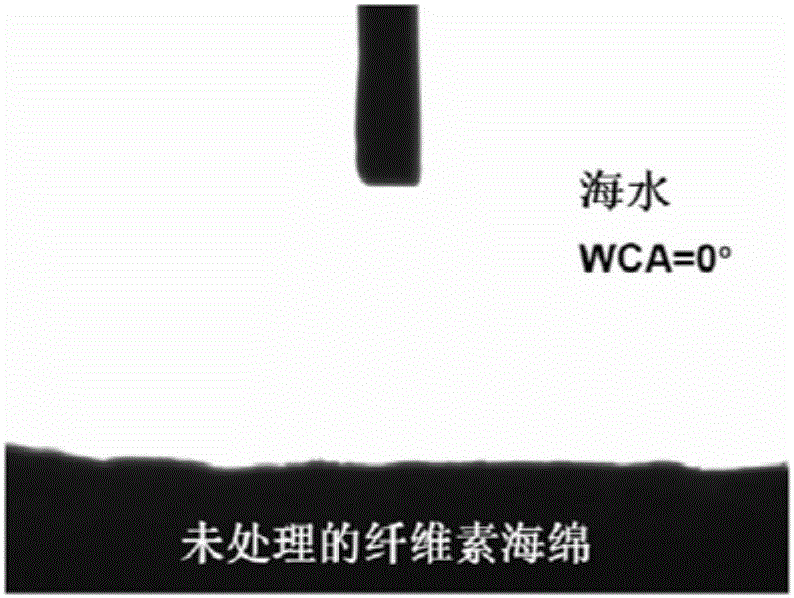

[0104] Example 1: In the superhydrophobic-superoleophilic cellulose sponge provided in this example, the sponge matrix is exactly the same as the sponge selected in Comparative Example 1, and both are three-dimensional porous cellulose sponges with an average pore diameter of 300 μm. However, in this embodiment, ZnO micro-nano structures are grown on the substrate, and hydrophobic chemical groups are grafted. The hydrophobic group is the growth of cellulose sponge with ZnO structure and the hydrophobic compound CH 3 (CH 2 ) 7 Si(OCH 3 ) 3 The hydrolyzate reacts, the -Si(OH) in the hydrolyzate 3 The functional groups and the hydroxyl groups in the cellulose sponge are bonded by chemical bonds and grafted onto the surface of the sponge.

[0105] The preparation method of the superhydrophobic-superoleophilic cellulose sponge of the present embodiment is as follows:

[0106] (1) is exactly the same as step (1) in comparative example 1;

[0107] (2) Add 0.02mol Zn(NO 3 ) ...

Embodiment 2

[0115] Example 2: The superhydrophobic-superoleophilic cellulose sponge used in this example is prepared in the same way as the superhydrophobic-superoleophilic cellulose sponge in Example 1, except that the average pore size of the sponge matrix is 500 μm cellulose sponge.

[0116] The above-mentioned superhydrophobic-superoleophilic cellulose sponge is carried out oil-absorbing property test, and test method is exactly the same as the method in comparative example 1, and the results are as follows:

[0117] After 3 minutes, the cellulose sponge was completely submerged in crude oil, and weighed after taking out the cellulose sponge: the oil absorption of the cellulose sponge was 27.5g / g, and the cellulose sponge was subjected to a speed of 2000 rpm After centrifugation for 1 minute, the oil retention rate was measured to be 90.2%.

[0118] Similar to Example 1, compared with the cellulose sponge in Comparative Example 1, the cellulose sponge in this Example 2 has excellen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com