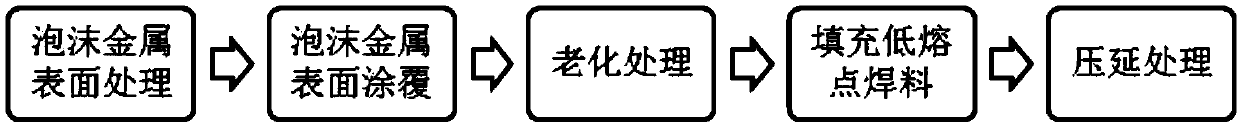

A kind of preparation method of metal foam composite solder sheet

A foam metal and metal solder technology, applied in metal processing equipment, metal material coating technology, welding equipment, etc., can solve the problem that the real addition amount of elements is difficult to accurately control, cannot improve the performance of solder, and the particle reinforcement phase is difficult to achieve. Uniform distribution and other issues to achieve the effect of reducing the content of weak structures, facilitating welding operations, and improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

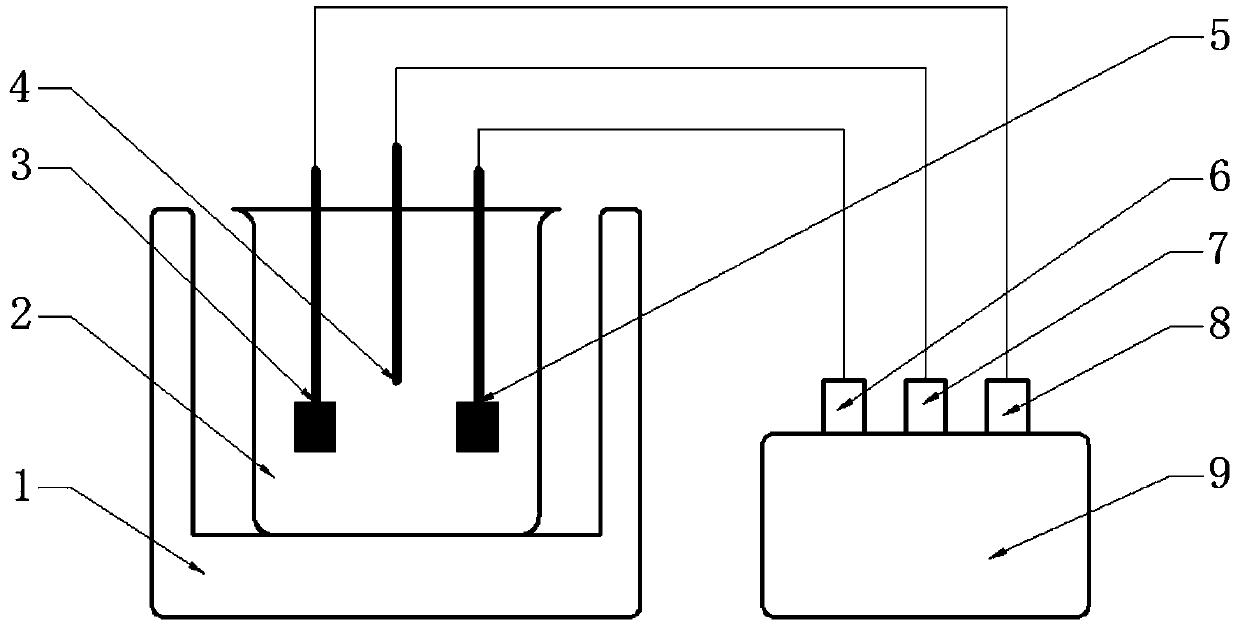

[0025] The metal foam substrate selected in this embodiment is spherical open-cell aluminum foam, the electroplating active metal coating is nickel, and the Sn metal substrate is pure Sn alloy. The specific operation steps are as follows:

[0026] After the aluminum foam with a size of 60mm×80mm has been degreased and derusted, it is cleaned in an ultrasonic environment for 10 minutes, and then the surface is roughened and cleaned with ultrasonic cleaning and deionized water for 10 minutes each; preheated in a deionized water bath for 10 minutes, The preheating temperature is 40°C, followed by ultrasonic assisted plating. The anode is a nickel plate, the cathode is the aluminum foam workpiece to be plated, the electroplating temperature is 40°C, the electroplating time is 30min, and the current density is 1A / dm 2 ; Ultrasonic power 5w / L, frequency 80kHz, ultrasonic action time 20min. After the electroplating is completed, the composite foamed aluminum material obtained is pla...

Embodiment 2

[0029] The metal foam substrate selected in this embodiment is spherical open-cell titanium foam, the electroplating active metal coating is Cu, and the Sn metal substrate is a Sn-Cu alloy. The specific steps are as follows:

[0030] After the titanium foam with a size of 50mm×90mm is degreased and derusted, it is cleaned in an ultrasonic environment for 12 minutes, and then the surface is roughened and cleaned with ultrasonic cleaning and deionized water for 12 minutes each; preheated in a deionized water bath for 10 minutes, The preheating temperature is 35°C, followed by ultrasonic assisted plating. The anode is graphite, the cathode is titanium foam workpiece to be plated, the electroplating temperature is 35°C, the electroplating time is 30min, and the current density is 1A / dm 2 ; Ultrasonic power 5w / L, frequency 80kHz, ultrasonic action time 20min. After the electroplating is completed, the composite aluminum foam material obtained is placed in soybean oil for dehydroge...

Embodiment 3

[0033] The metal foam substrate selected in this embodiment is spherical open-cell foam copper, the active metal coating is nickel, and the Sn metal substrate is a Sn-Zn alloy. The specific steps are as follows:

[0034]After the copper foam with a size of 50mm×90mm has been degreased and derusted, it is cleaned in an ultrasonic environment for 12 minutes, and then the surface is roughened and cleaned with ultrasonic waves and deionized water for 12 minutes each; preheated in a deionized water bath for 10 minutes, preheated The heat temperature was 50°C, followed by ultrasonic assisted plating. The anode is graphite, the cathode is copper foam workpiece to be plated, the electroplating temperature is 50°C, the electroplating time is 30min, and the current density is 2A / dm 2 ; Ultrasonic power 5w / L, frequency 60kHz, ultrasonic action time 20min. The components of the electroplating solution and the concentration of each component are as follows: NiSO 4 ·6H 2 O, 10g / L; NiCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com