Method for producing mold-pressing door planks through wood scraps

A technology of miscellaneous wood and molding, which is applied in the field of furniture, can solve problems such as easy cracking, high waste rate, and short miscellaneous wood fibers, so as to achieve humanized design and reduce inventory backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

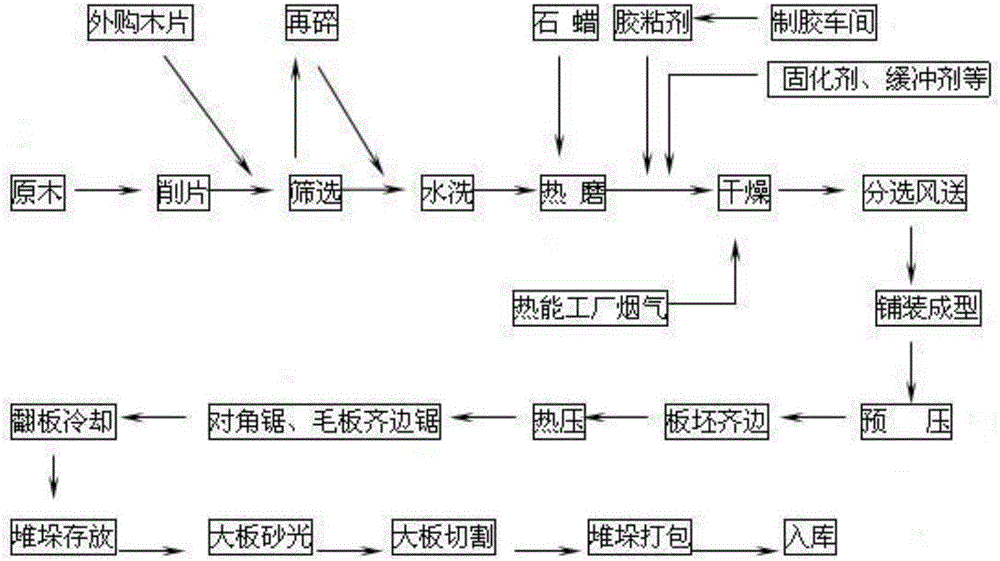

[0020] Example: such as figure 1 As shown, a method of producing molded door panels with miscellaneous wood, including chipping, sieving, washing, hot grinding, drying, paving, pre-pressing, hot-pressing and post-treatment after specification sawing, the main process is :

[0021] 1. Preparation means chipping and sorting:

[0022] 2. The small-diameter wood, branches and wood processing residues are chipped and screened (the small ones are sent to the thermal energy center as fuel, and the oversized wood chips are crushed by the re-crusher and incorporated into qualified wood chips, screened Use magnets before and after to remove iron).

[0023] The wood chips that meet the specifications are washed to remove stones, mud, sand, metal and other sundries, and then sent to the pre-steaming bin. The wood chips are heated and cooked by steam in the pre-heating bin. Enter the vertical cooker for cooking and softening treatment. After the softened wood chips are added with paraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com