Nano-holmium oxide preparation method

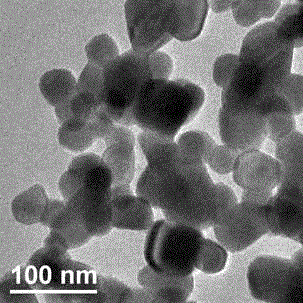

A kind of holmium oxide and nanotechnology, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of uneven product particles and poor dispersion, and achieve good dispersion, simple process and large specific surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: 1 kg of the final product nano holmium oxide was added into the reaction kettle to prepare a concentration of 0.3mol / L with pure water and a volume of holmium chloride solution of 17.64L after calculation. The measured temperature was 15 degrees, and then weighed Analyze pure sodium carbonate 1KG, be mixed with pure water concentration and be 0.4mol / L, volume is 23.58L, temperature is 15 degrees, takes by weighing the polyethylene glycol 20000 surfactant of final product nano holmium oxide mass ratio 10%, is 100g, add 1L pure water, heat to dissolve it into a liquid, put polyethylene glycol 20000 into the feed liquid holmium chloride, mix and stir for 15min, and finally add sodium carbonate evenly, and the dropping time is 35min, from which it can be calculated The adding speed is 0.67L / min, and the flow rate and adding speed are controlled by the governor. After the dropwise addition, continue to stir for 0.5 hours, age for 2 hours, soak and wash with hot pur...

Embodiment 2

[0013] Example 2: The final product nano holmium oxide 5KG was calculated and added into the reaction kettle with pure water to prepare a holmium chloride solution with a concentration of 0.4mol / L and a volume of 66.16L. The measured temperature was 17 degrees, and then weighed Analytical pure sodium carbonate 5KG, prepared with pure water to a concentration of 0.4mol / L, a volume of 117.92L, a temperature of 18 degrees, weighed the final product nano holmium oxide quality 3% polyethylene glycol 4000 surfactant, 150g , add 4L of pure water, heat to dissolve it into a liquid, put polyethylene glycol 4000 into the feed liquid holmium chloride and mix and stir for 15 minutes, and finally add sodium carbonate dropwise evenly, and the dropping time is 107 minutes, from which it can be calculated The speed is 1.1L / min, and the flow rate and adding speed are controlled by the governor. After the dropwise addition, continue to stir for 0.5 hours, age for 3 hours, soak and wash with hot ...

Embodiment 3

[0014] Example 3: 1kg of the final product nano holmium oxide was calculated and added into the reactor with pure water to prepare holmium chloride with a concentration of 0.1mol / L and a volume of 52.93L. The measured temperature was 15 degrees, and then weighed and analyzed Pure sodium carbonate 1KG, is mixed with pure water concentration and is 0.2mol / L, and volume is 47.17L, and temperature is 15 degrees, takes by weighing the polyethylene glycol 2000 surfactant of final product nano holmium oxide quality 15%, is 150g, Add 1L of pure water, heat to dissolve it into a liquid, put polyethylene glycol 2000 into the material liquid holmium chloride, mix and stir for 15 minutes, and finally add sodium carbonate dropwise evenly, and the dropping time is 45 minutes, from which the adding speed can be calculated It is 1.05L / min, and the flow rate and adding speed are controlled by the governor. After the dropwise addition, continue to stir for 0.5 hours, age for 2 hours, soak and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com