Preparation method of structure-controllable CdS nanometer materials

A technology of nanomaterials and reactors, which is applied in the field of preparation of CdS nanomaterials, can solve problems that are rarely reported, and achieve the effects of good repeatability, strong photocatalytic activity, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the CdS nanomaterial with controllable structure of the present invention specifically comprises the following steps:

[0034] Step (1), Cd(Ac) 2H 2 O and R 1 NHCSNHR 2 Added to the liner of the reactor, where Cd(Ac)·2H 2 O and R 1 NHCSNHR2 The molar ratio is 1:1~10. And as long as there is a corresponding container, it can be prepared in large quantities;

[0035] Step (2), add the mixed binary system solution of diethylenetriamine DETA and deionized water into the inner tank of the reactor, and the mixed binary system solution of diethylenetriamine DETA and deionized water added to the inner tank of the reactor The volume of the system solution accounts for 75% to 85% of the inner tank volume of the reactor. The volume ratio of diethylenetriamine DETA to deionized water is 50:1~1:10.

[0036] Satisfied: 1~6mmol of Cd(Ac)·2H is added to every 100mm of the mixed binary system solution of diethylenetriamine DETA and deionized water 2 O. ...

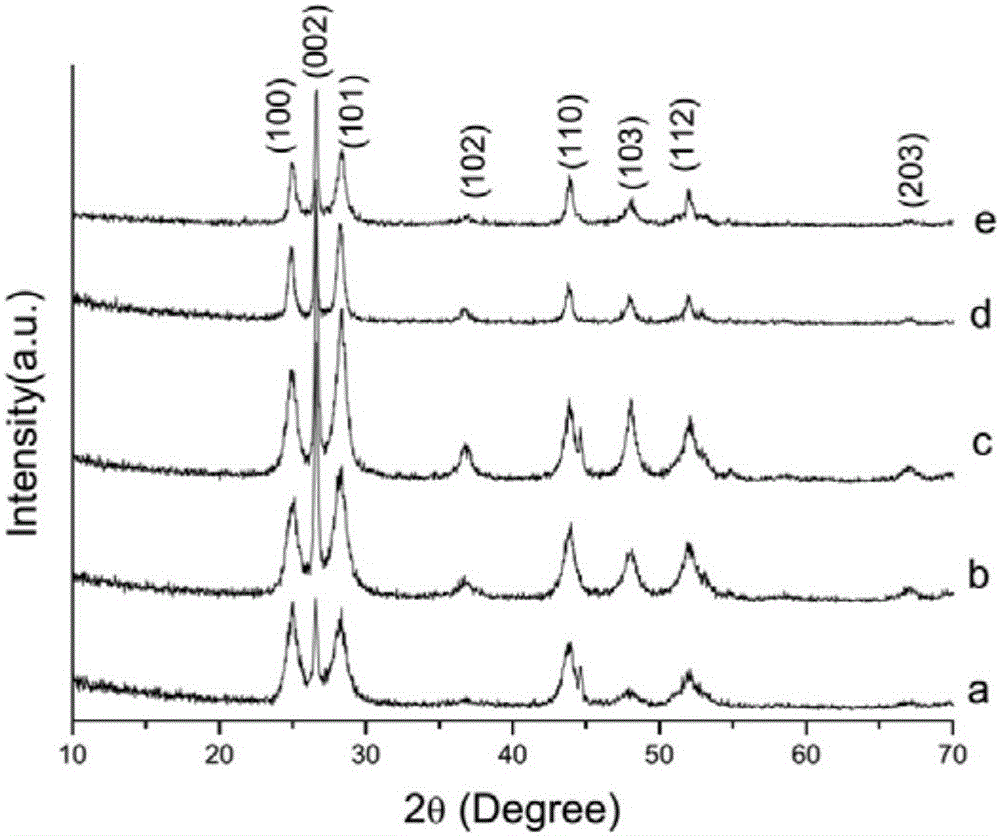

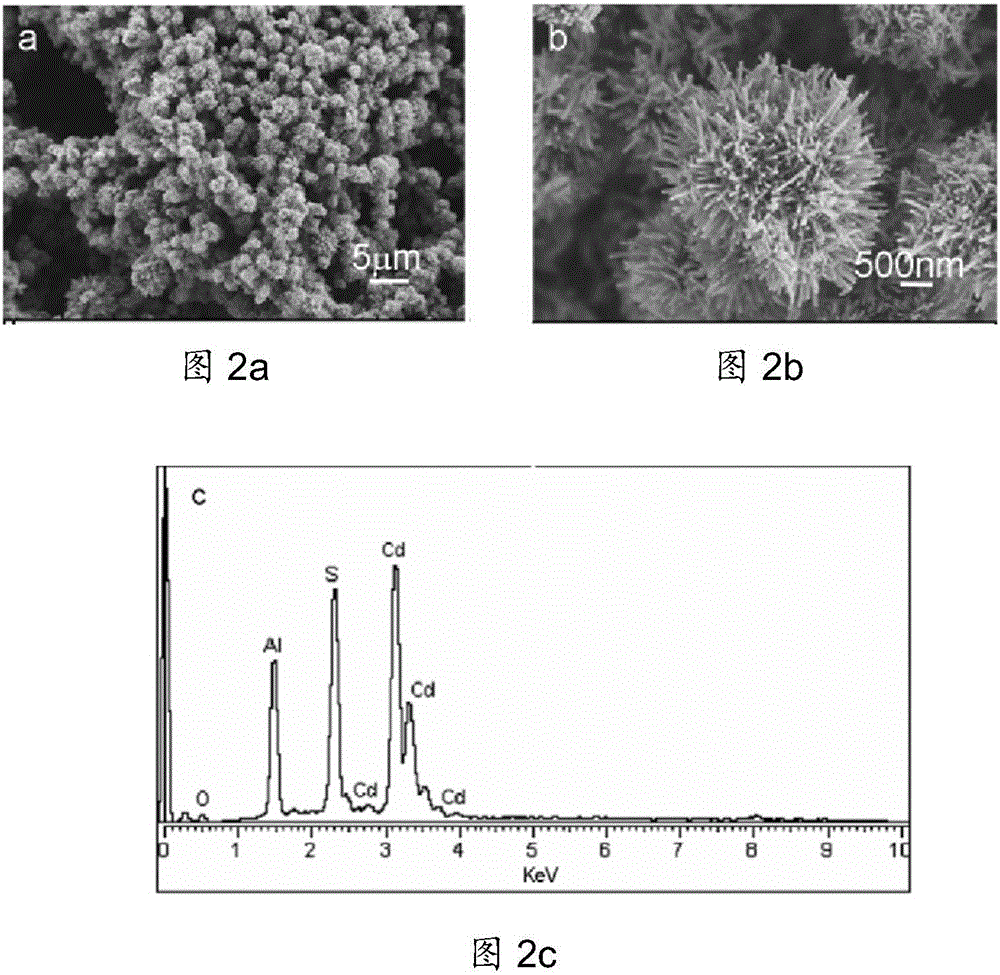

Embodiment 1

[0041] One-step synthesis of CdS nanomaterials by solvothermal method, firstly take 1 mmol of Cd(Ac) 2H 2 O and NH 2 CSNHCH 3 Add it into the inner tank of the reaction kettle, the volume of the inner tank is 50mL, take the mixed binary system solution of diethylenetriamine (DETA) and deionized water in different proportions, and add it to the inner tank, the volume added is to fill the inner tank 80% of the volume, the ratio of diethylenetriamine (DETA) to deionized water is: (a) 33:4; (b) 7:1; (c) 1:1; (d) 2:5; ( d) 1:7; put the reaction kettle into an oven and react at 180°C for 12 hours, then take it out and cool it down to room temperature naturally; the obtained product is centrifuged, washed with distilled water and absolute ethanol, the centrifugation rate is 6000r / min, and the centrifugation time is 5min , distilled water and absolute ethanol were washed 3 to 5 times each; the cleaned product was vacuum-dried at 60° C. for 6 hours to obtain CdS nanomaterials. R in ...

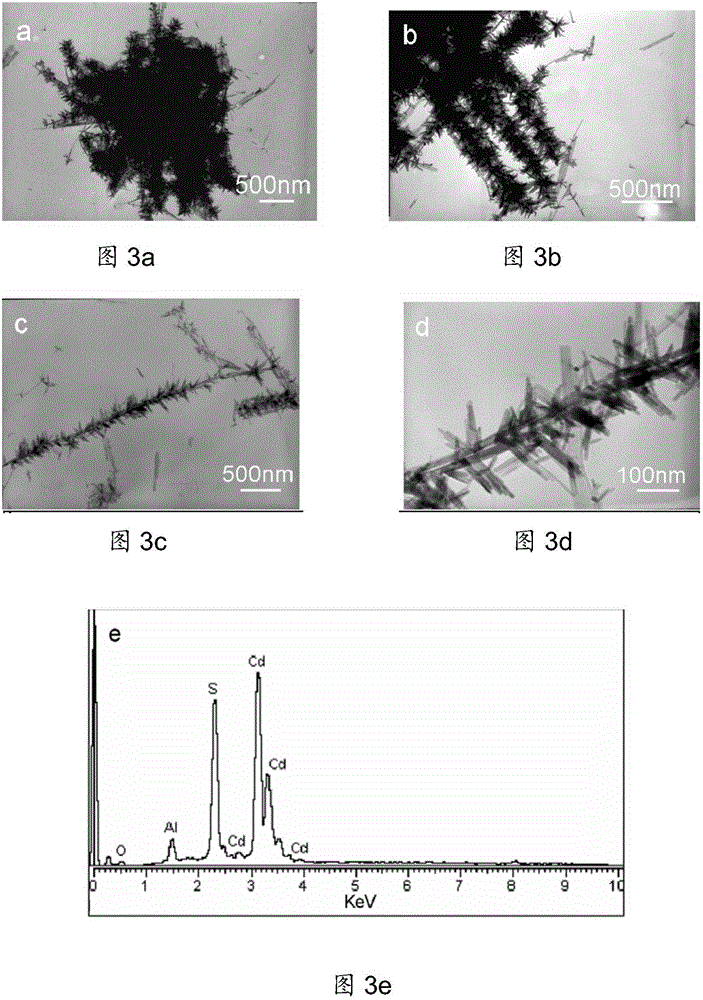

Embodiment 2

[0050] One-step synthesis of CdS nanomaterials by solvothermal method, firstly take 2 mmol of Cd(Ac) 2H 2 O and NH 2 CSNH (NO 2 ) into the inner tank of the reaction kettle, the volume of the inner tank is 50mL, and the mixed binary system solution of diethylenetriamine (DETA) and deionized water in different proportions is added to the inner tank, and the added volume is filled to the inner tank 80% of the gallbladder volume, the ratio of diethylenetriamine (DETA) to deionized water is: (a) 33:4; (b) 7:1; (c) 1:1; (d) 2:5; (d) 1:7; put the reaction kettle into an oven and react at 180°C for 12 hours, then take it out and cool it down to room temperature naturally; the obtained product is centrifuged, washed with distilled water and absolute ethanol, and the centrifugation rate is 8000r / min, and the centrifugation time is After 10 minutes, wash with distilled water and absolute ethanol for 3 to 5 times respectively; the cleaned product was vacuum-dried at 60° C. for 10 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com