Method for controlled macroscopic preparation of molybdenum disulfide nano strip

A technology of molybdenum disulfide and nano-strips, applied in the direction of molybdenum sulfide, etc., can solve the problems of staying in theoretical calculations, high equipment requirements, and no promotion, and achieve the effects of stable properties, simple production equipment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Accurately weigh 0.753g of sulfur element and 0.452g of molybdenum trioxide strip, place sulfur element and molybdenum trioxide strip in porcelain boats respectively, and then put the porcelain boats into two In the temperature zone;

[0034] (2) Set the temperature range of the dual temperature zone tube furnace, set the temperature zone where the sulfur element is located to rise to 200°C, set the temperature zone where the molybdenum trioxide strip is located to rise to 450°C, and set the holding time to 10min;

[0035] (3) Clean the tube furnace with argon before starting heating (starting the tube furnace heating), and keep argon flowing continuously during the heating process and heat preservation process, and the argon gas flow rate is 1mL / s;

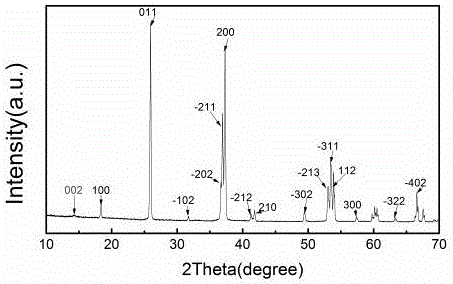

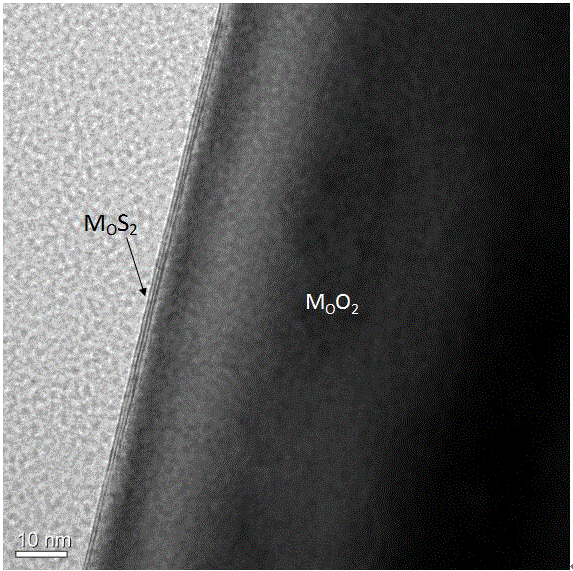

[0036] (4) After the heat preservation is completed, open the furnace to cool down quickly, and take out the porcelain boat to obtain single-layer or few-layer molybdenum disulfide nano-strips grown on the edge of the ...

Embodiment 2

[0038] (1) Accurately weigh 0.902g of elemental sulfur and 0.479g of strips of molybdenum trioxide, respectively, place the elemental sulfur and strips of molybdenum trioxide in quartz boats, and then put the quartz boats into the two chambers of the dual-temperature zone tube furnace. within a temperature zone;

[0039] (2) Set the temperature range of the tube furnace with dual temperature zones, set the temperature zone where the sulfur element is located to a temperature of 200°C, set the temperature zone where the molybdenum trioxide strip is located to a temperature of 500°C, and set the holding time to 5 minutes;

[0040] (3) After cleaning the tube furnace with argon gas, start heating the tube furnace, and keep the nitrogen gas flowing continuously, and the argon gas flow rate is 1mL / s;

[0041] (4) After the heat preservation is completed, open the furnace to quickly cool down;

[0042] (5) Set the temperature zone where the molybdenum trioxide strip is placed to ri...

Embodiment 3

[0046] (1) Accurately weigh 0.681g of elemental sulfur and 0.352g of molybdenum trioxide strips, place them in porcelain crucibles, and then put the two porcelain crucibles into the two temperature zones of the dual-temperature zone tube furnace;

[0047] (2) Set the temperature range of the dual temperature zone tube furnace: set the temperature of the temperature zone where the sulfur element is located to 300°C, set the temperature zone where the molybdenum trioxide strip is located to 750°C, and set the holding time to 40min;

[0048] (3) Clean the tube furnace with argon, start heating while keeping argon flowing continuously, the amount of argon flowing is 50mL / s;

[0049] (4) After the heat preservation is completed, the furnace is opened to cool down quickly, and the molybdenum disulfide nanoribbons grown on the edge of molybdenum dioxide with two to four layers can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com